Finite element method for on-line board temperature calculation in course of hot rolling

A hot rolling process, finite element technology, applied in the field of rolling, can solve problems such as low precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

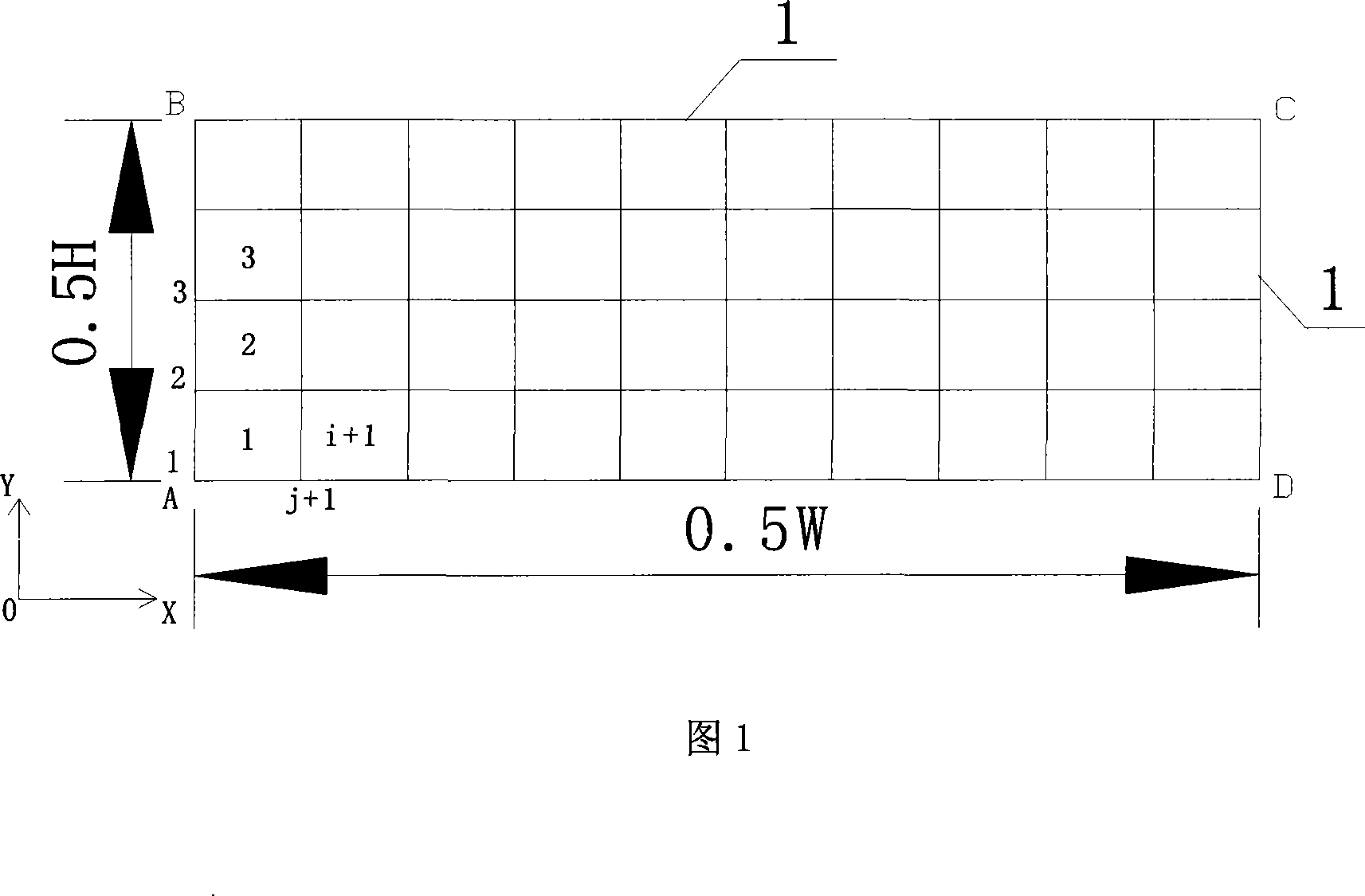

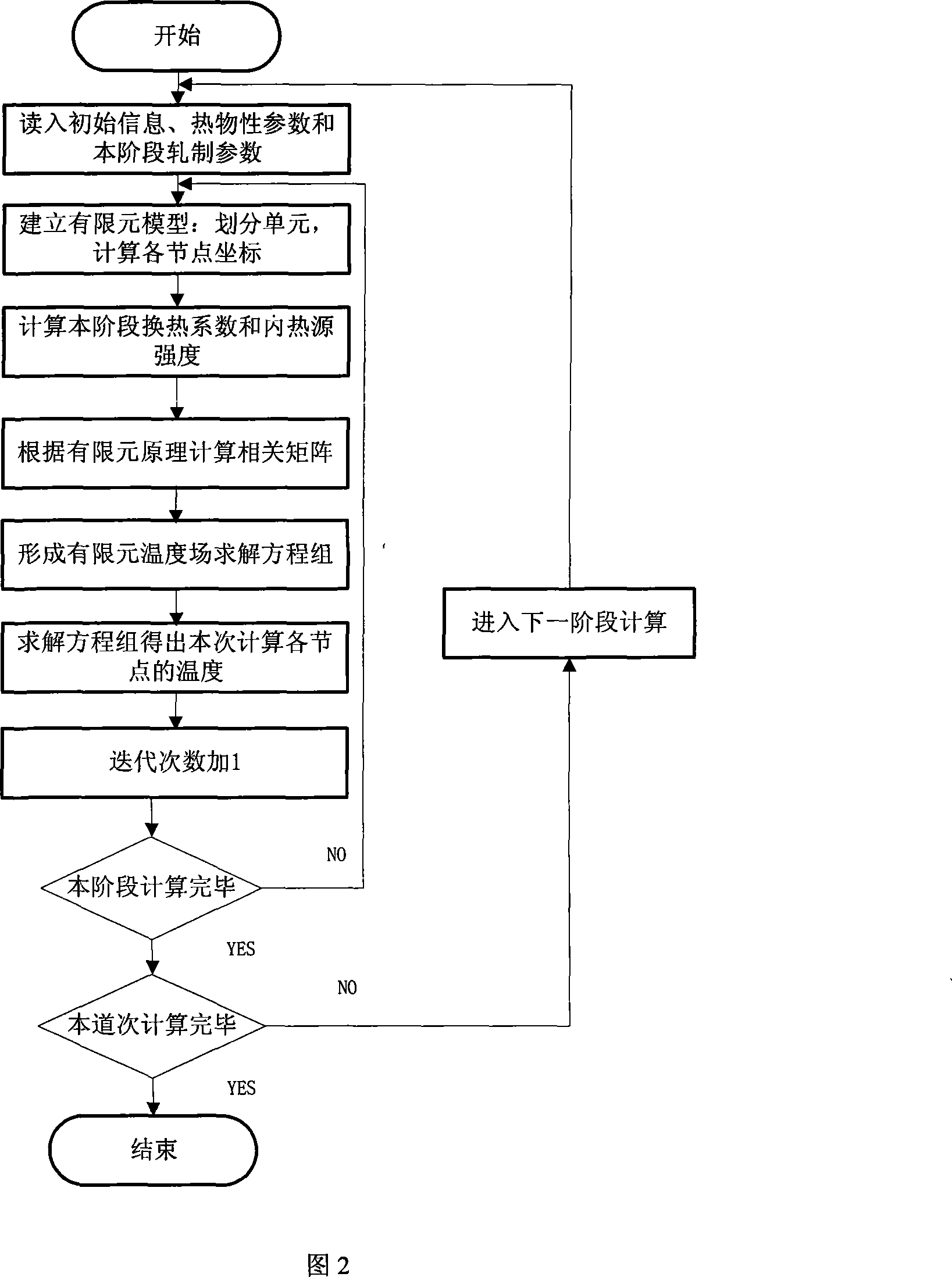

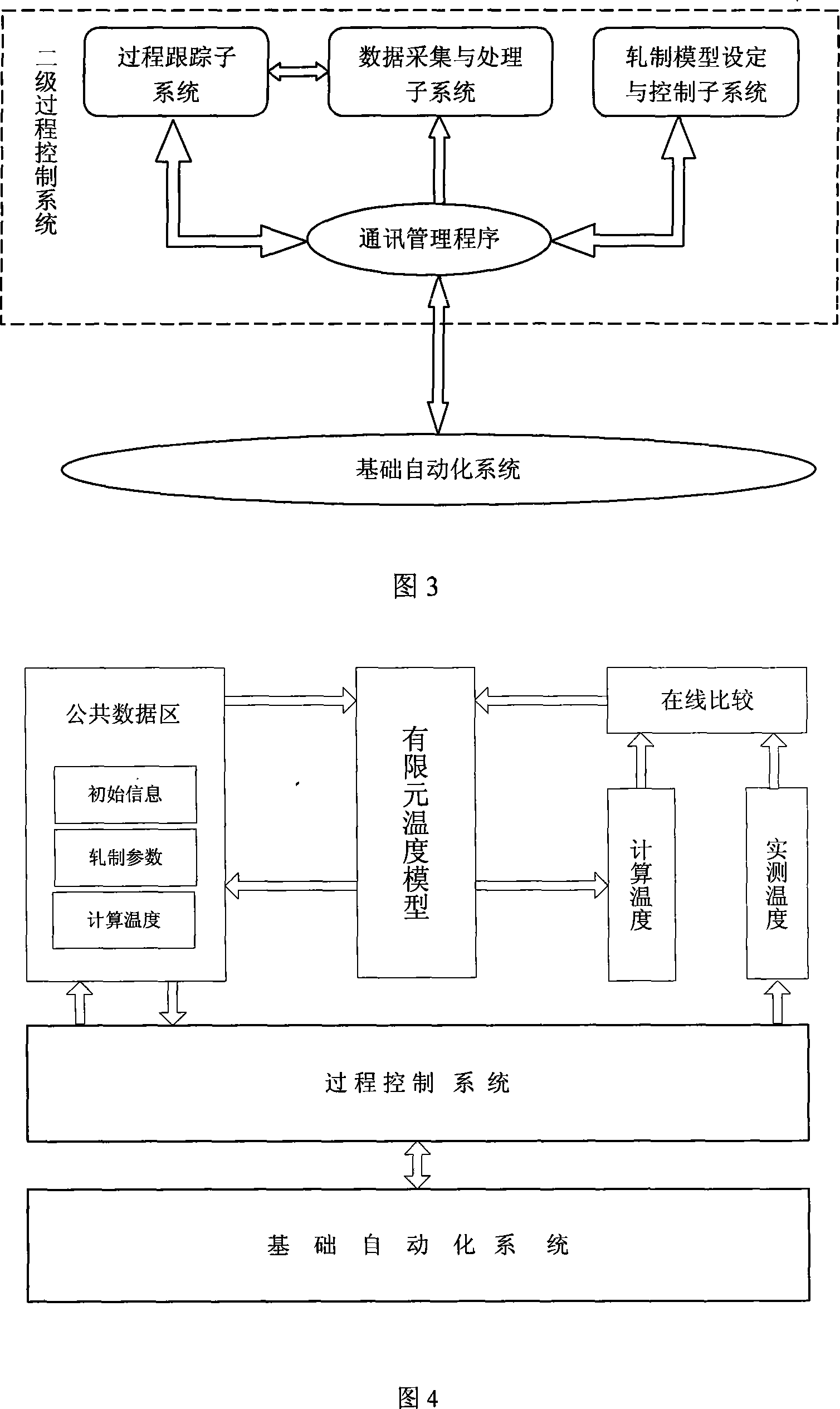

Method used

Image

Examples

Embodiment Construction

[0091] The process layout of the production of a medium and thick plate is shown in Figure 5.

[0092] The rolling process is as follows: the billet is put into the furnace and heated to the corresponding temperature → out of the furnace for high-pressure water descaling → transported to the rolling mill for forming rolling → widening and rolling after transfer → elongation and rolling after transfer to the final Dimensional requirements → transport to accelerated cooling system for cooling → straightening.

[0093] The above process is for conventional rolling; for the controlled rolling process, its elongation rolling process is divided into two stages: the stage before warming (equivalent to air cooling for a long time) and the post-warming stage. After the rolled piece is rolled to a certain thickness in the pre-warming stage, it is transported to the warming roller table for waiting temperature, gradually cooled to the specified rolling temperature, and then starts rollin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com