Improved high-efficiency unidirectional heat transfer pipe used for heat dissipation of microelectronics

A microelectronic and high-efficiency technology, applied in the field of heat pipes, can solve the problems of low condensation heat transfer coefficient, low heat transfer coefficient of evaporation section, and does not consider bead condensation, so as to improve condensation heat transfer coefficient and reduce viscous adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention are specifically described below in conjunction with the accompanying drawings:

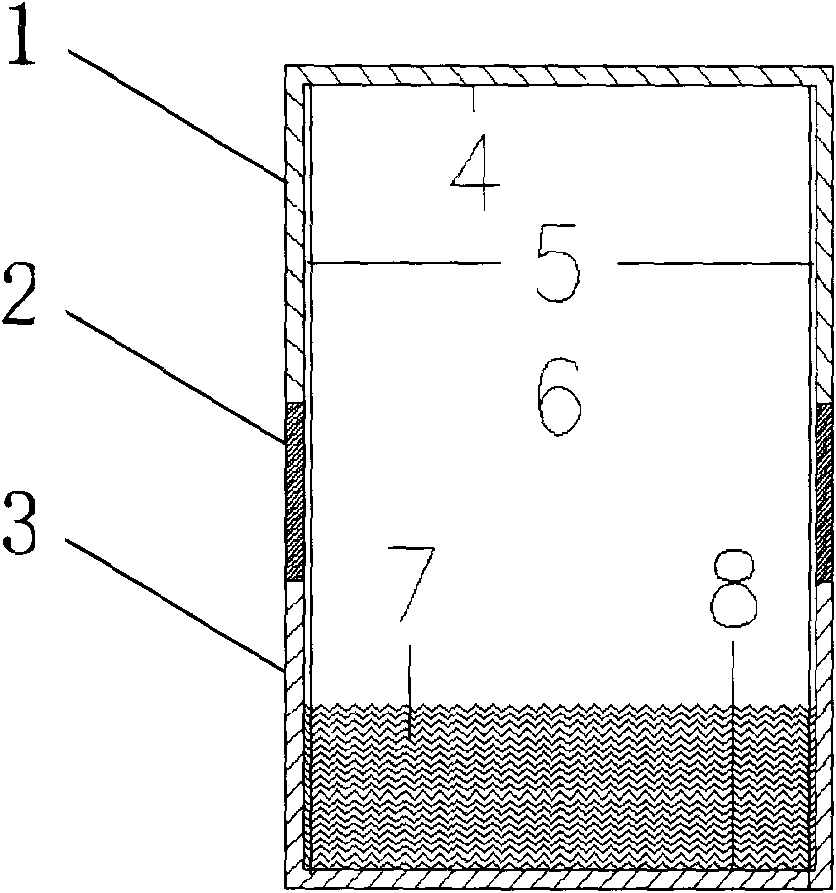

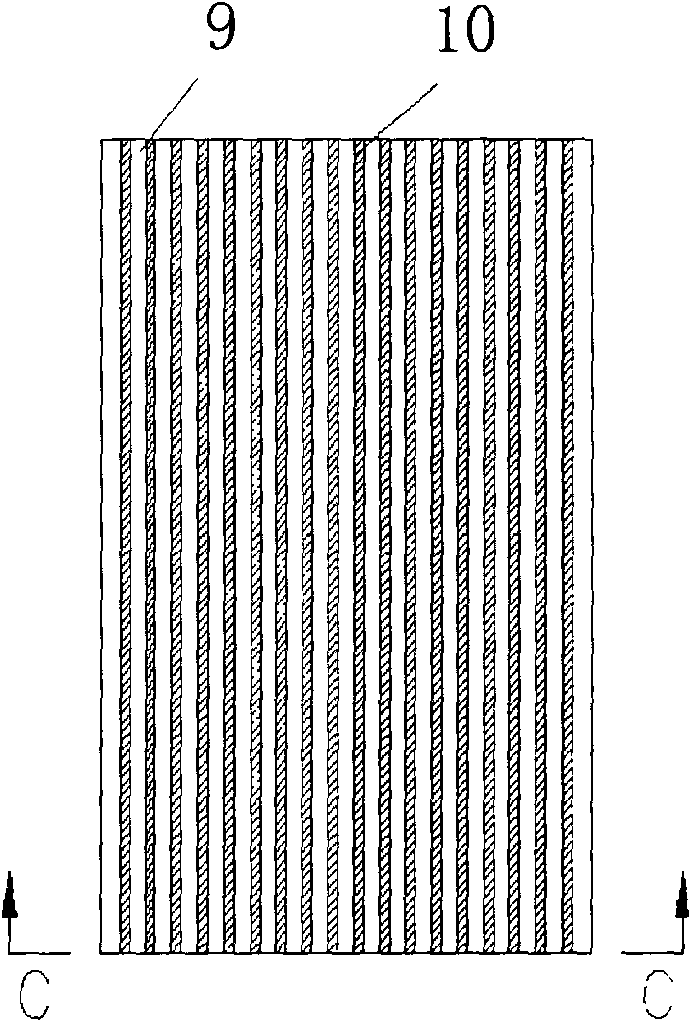

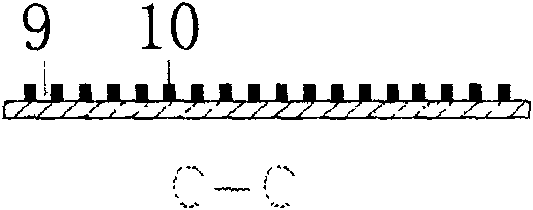

[0018] attached figure 1 It is a cross-sectional view of a heat pipe, including a condensation section 1, an adiabatic section 2, an evaporation section 3, a top of the condensation section 4, a capillary column channel 5, a closed vacuum chamber 6, a heat pipe working medium 7, and a scratched shallow groove surface 8. Among them, the condensing section 1 and the evaporating section 3 are made of materials with high thermal conductivity, such as copper, and the thermal conductivity is 394-401W / m K; the thermal insulation section 2 is made of materials with low thermal conductivity, such as steel, which has a thermal conductivity The coefficient is 36~54W / m·K; the three are seamlessly welded to form a whole; then the capillary channel 5 with channel structure is processed on the inner wall; the channel structure is as attached figure 2 , 3 As shown, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com