Method and apparatus for measuring solid interface contact heat exchange coefficient

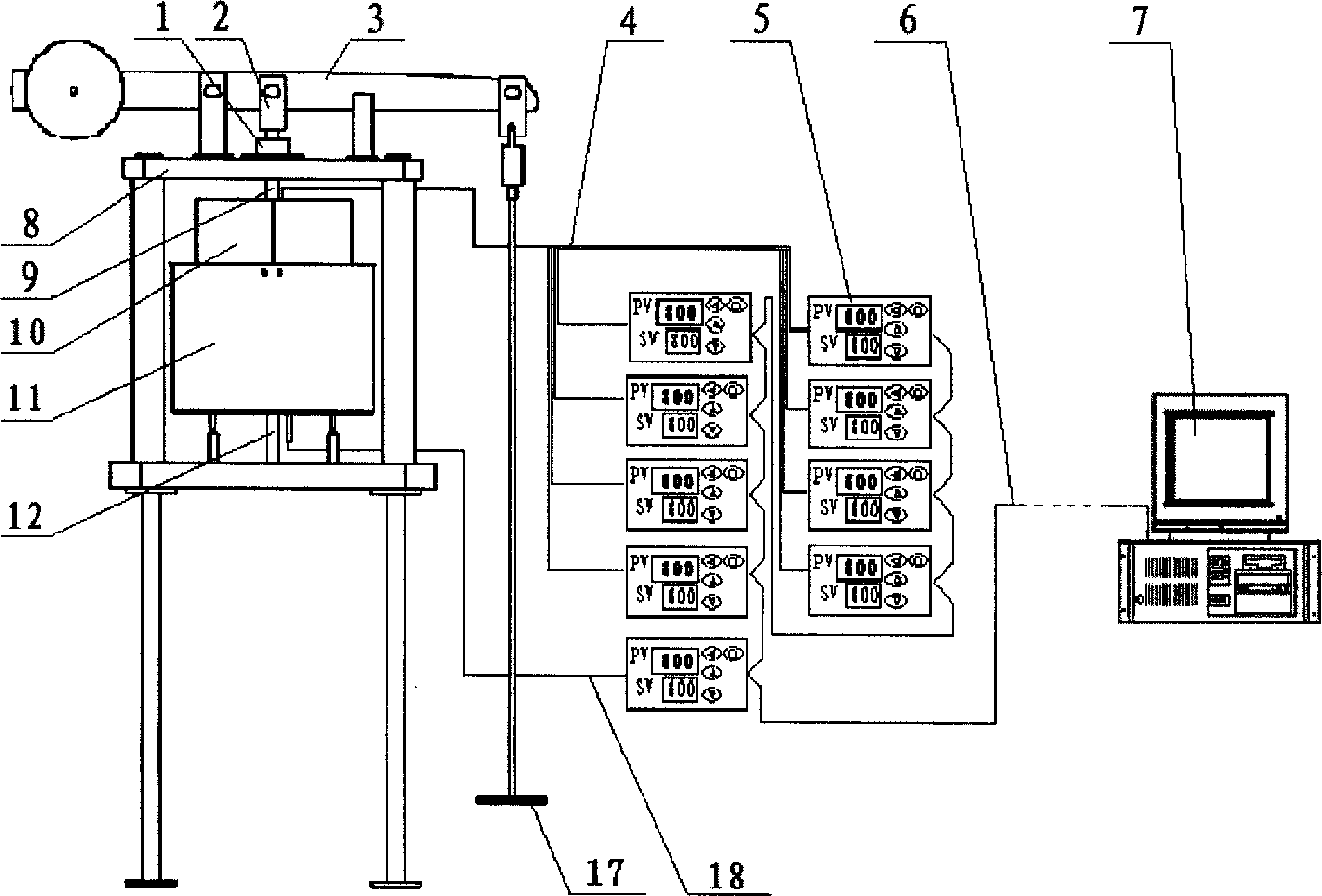

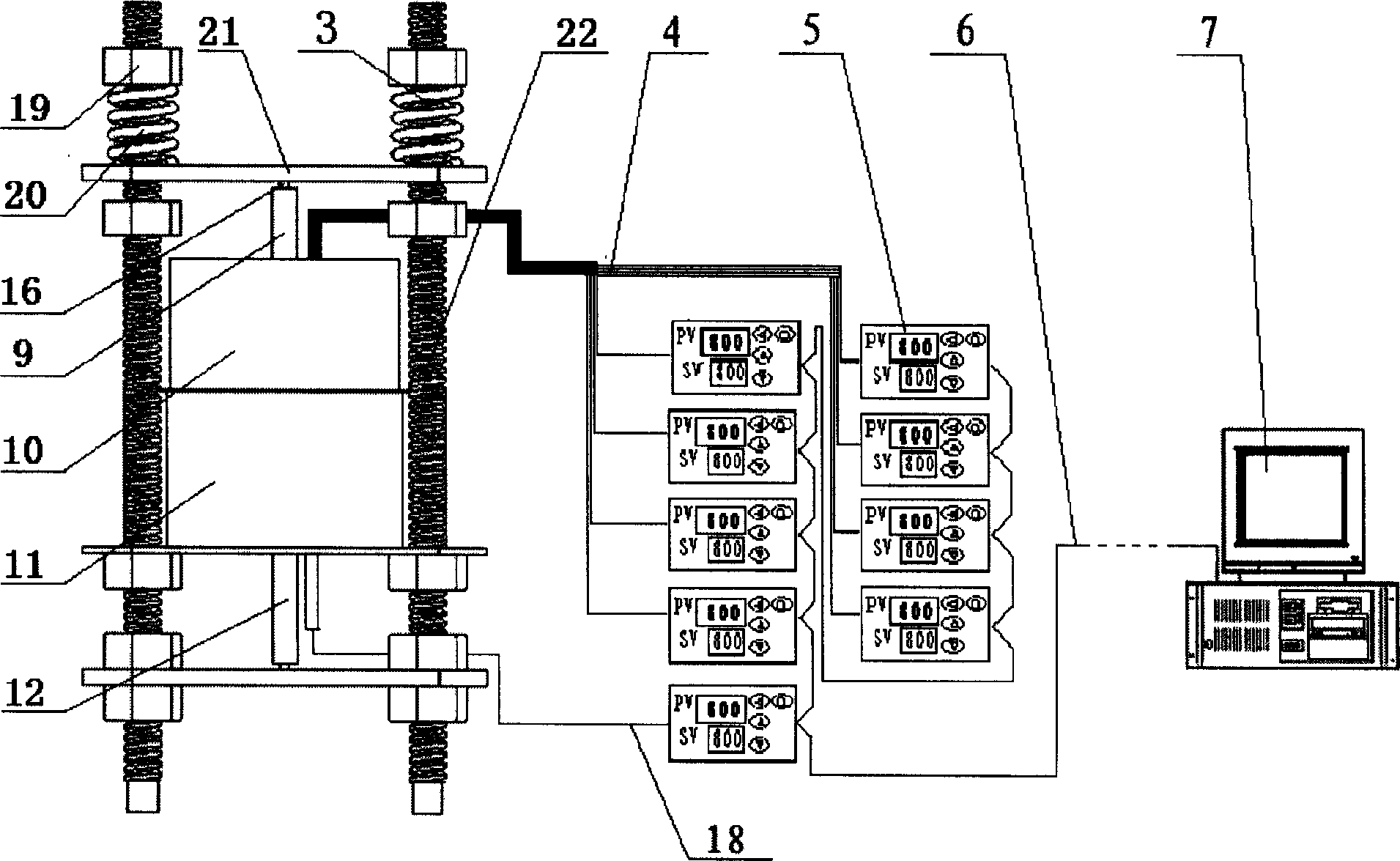

A technology of heat transfer coefficient and solid interface, applied in the field of plastic processing research, which can solve the problems of low measurement temperature of measurement equipment, unintuitive data acquisition and processing, and large measurement error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

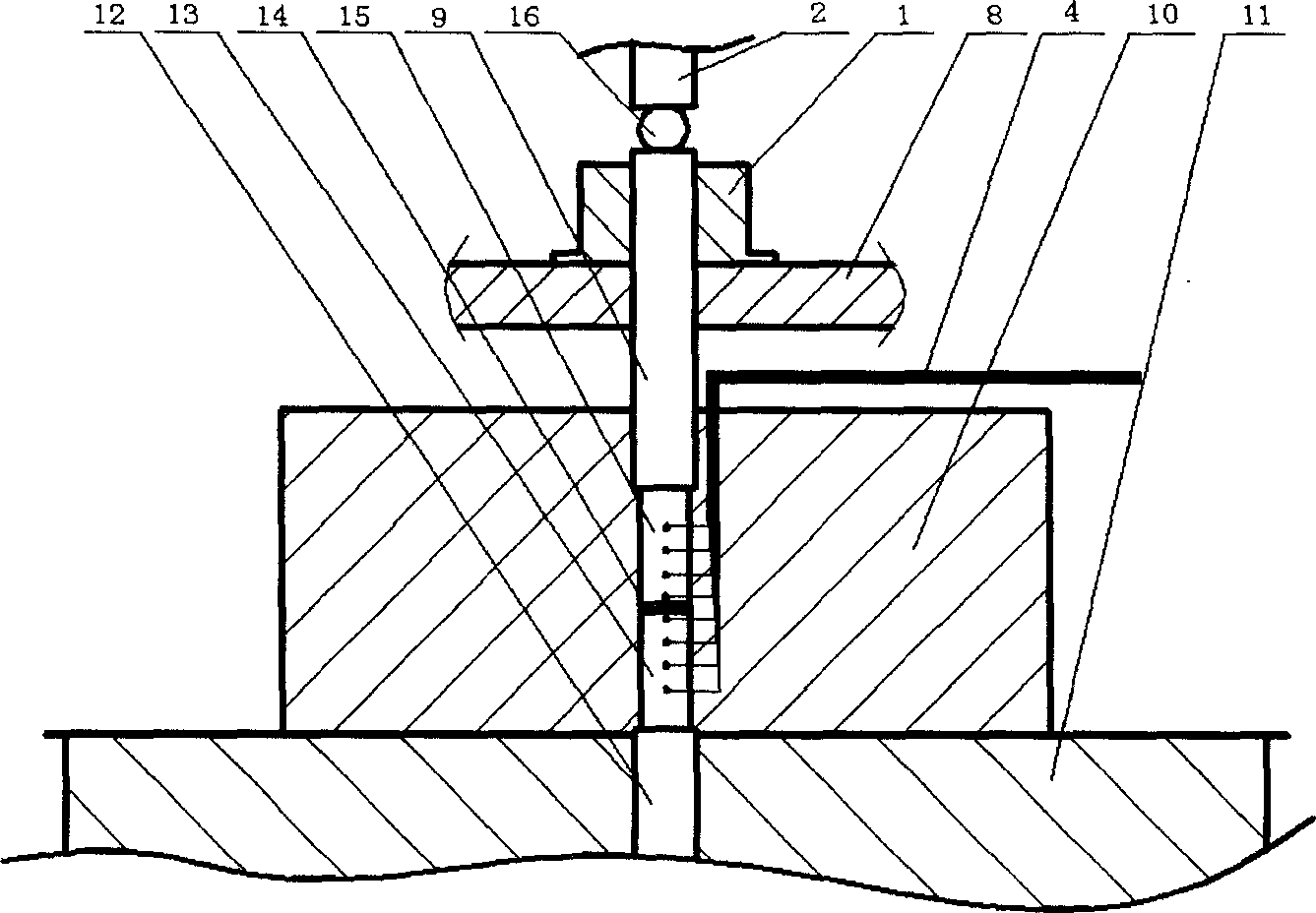

[0035] The material of the first sample 13 is 7050 extruded aluminum alloy, the material of the second sample 15 is 5CrMnMo die steel, the diameter of the sample is: Φ20, the length is: 50mm, and the measurement is carried out under the condition that the contact surface pressure is 1740N. For the contact heat transfer coefficients when the temperature of the heating furnace 11 is 300°C, 400°C, 500°C, and 600°C, a sheet 14 of the same material as that of the first sample 13 and the second sample 15 is added between the contact surfaces , the stacking of the slices 14 is alternate stacking, the surface state of the slices 14 is the same as the surface state of the sample, the same surface state includes: the same surface roughness, the same intermediate medium, etc., here the surface of the sample and the slice 14 is polished by sandpaper , the sandblasting treatment makes the sample and the sheet 14 have the same surface roughness, the number of the sheet 14 is 6, and the purpo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com