Thermal model modeling method for lithium ion battery pack based on air-cooling heat dissipating mode

A technology of lithium-ion battery packs and heat dissipation methods, which is applied in the fields of electrical digital data processing, instruments, and calculations, and can solve the problems of complex calculation process, large amount of calculation, and low model accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The present invention includes

[0082] (1) A formula common to all cells in the battery pack;

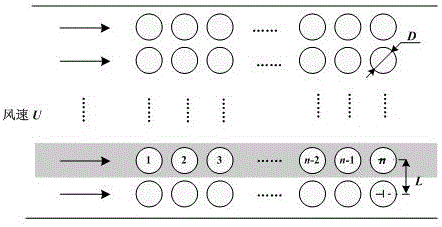

[0083] (2) The formulas for the first and last single cells in a certain row of the battery pack obtained on the basis of the common formula for all single cells in the battery pack;

[0084] (3) The minimum temperature and maximum temperature of the battery pack are represented by the temperature of the first and last single battery in a row;

[0085] (4) The battery pack is composed of individual cells. In order to obtain the temperature range of the battery pack, the thermal model of the battery pack is composed of the thermal models of the first and last batteries.

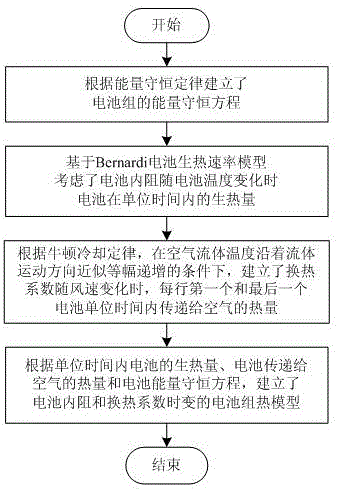

[0086] The invention provides a thermal model modeling method of a lithium-ion battery pack based on an air-cooled heat dissipation method. The modeling process is as follows: figure 1 shown. The specific implementation steps are:

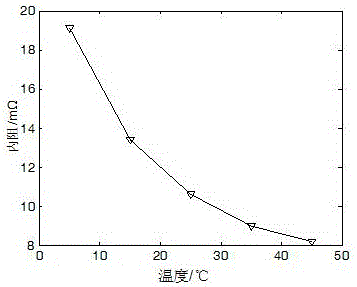

[0087] 1. Establish the energy conservation equation of the lithium-ion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com