Device and method for evaluating relation of interface temperature and interface heat exchange coefficient

A technology of interface heat transfer coefficient and temperature detection device, which is applied in the direction of using electrical devices, thermometers, and thermometers using electric/magnetic elements that are directly sensitive to heat, can solve problems that do not involve contact interface temperature and interface heat transfer coefficient, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be further described below in conjunction with the accompanying drawings.

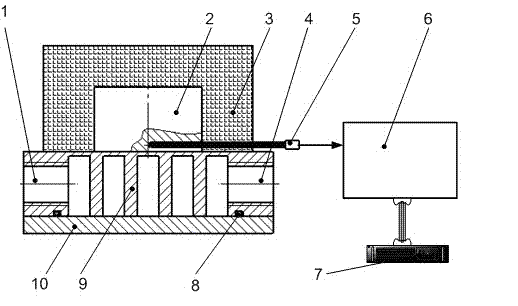

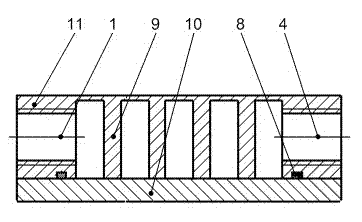

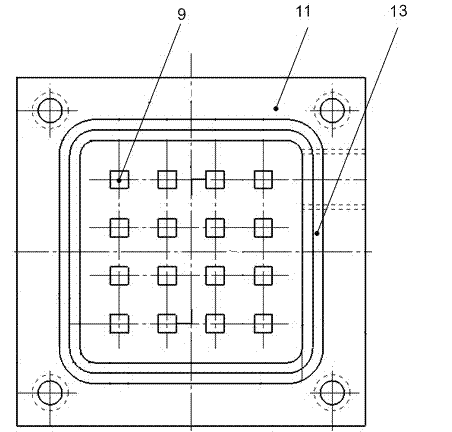

[0071] A device for evaluating the relationship between mold surface temperature and interface heat transfer coefficient during hot stamping, including a cooling device, a sample fixing device and a temperature detection device. The cooling device includes an upper tooling 11 and a lower tooling 10, the upper tooling 11 and the lower tooling 10 are connected by fastening screws, the lower surface of the upper tooling 11 in contact with the lower tooling 10 is provided with a sealing groove 13, and the sealing A sealing ring 8 is installed in the groove 13, and the cooling device is sealed through the compression deformation of the sealing ring 8 to prevent leakage of cooling water. The surface thickness of the upper tooling 11 is 2mm, which reduces the influence of the change of the thermal physical property parameters of the tooling material on the calculation accurac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com