Female screw heat-transfer pipe

A heat transfer tube and internal thread technology, which is applied to the field of aluminum and aluminum-based alloy seamless internal thread heat transfer tubes for air conditioning and refrigeration, can solve the problem of reduced heat transfer performance of heat transfer tubes, unfavorable Grigorich effect, and obstruction of refrigerants. flow and other problems, to achieve the effect of maintaining heat exchange effect, reducing weight, and facilitating recycling and reuse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

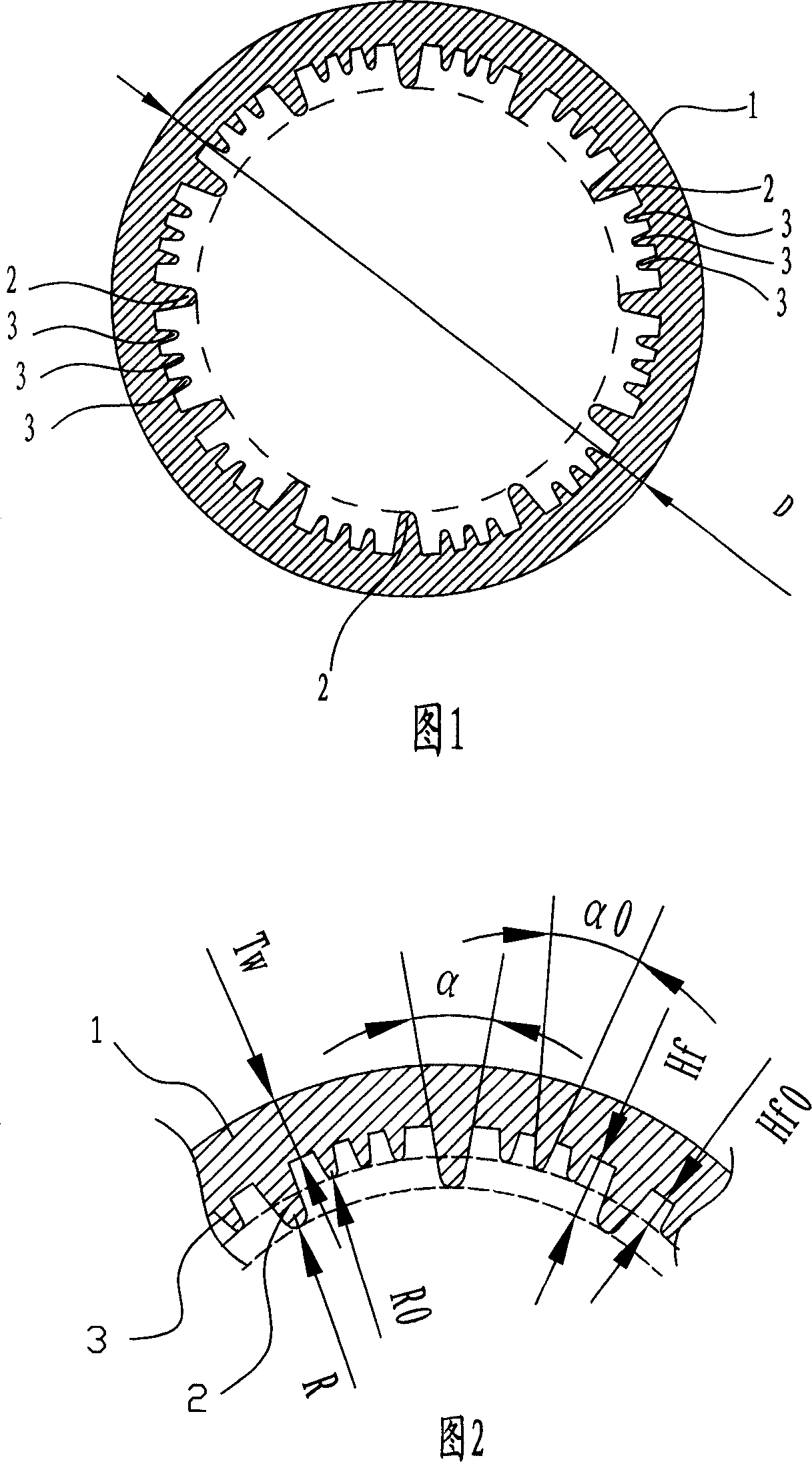

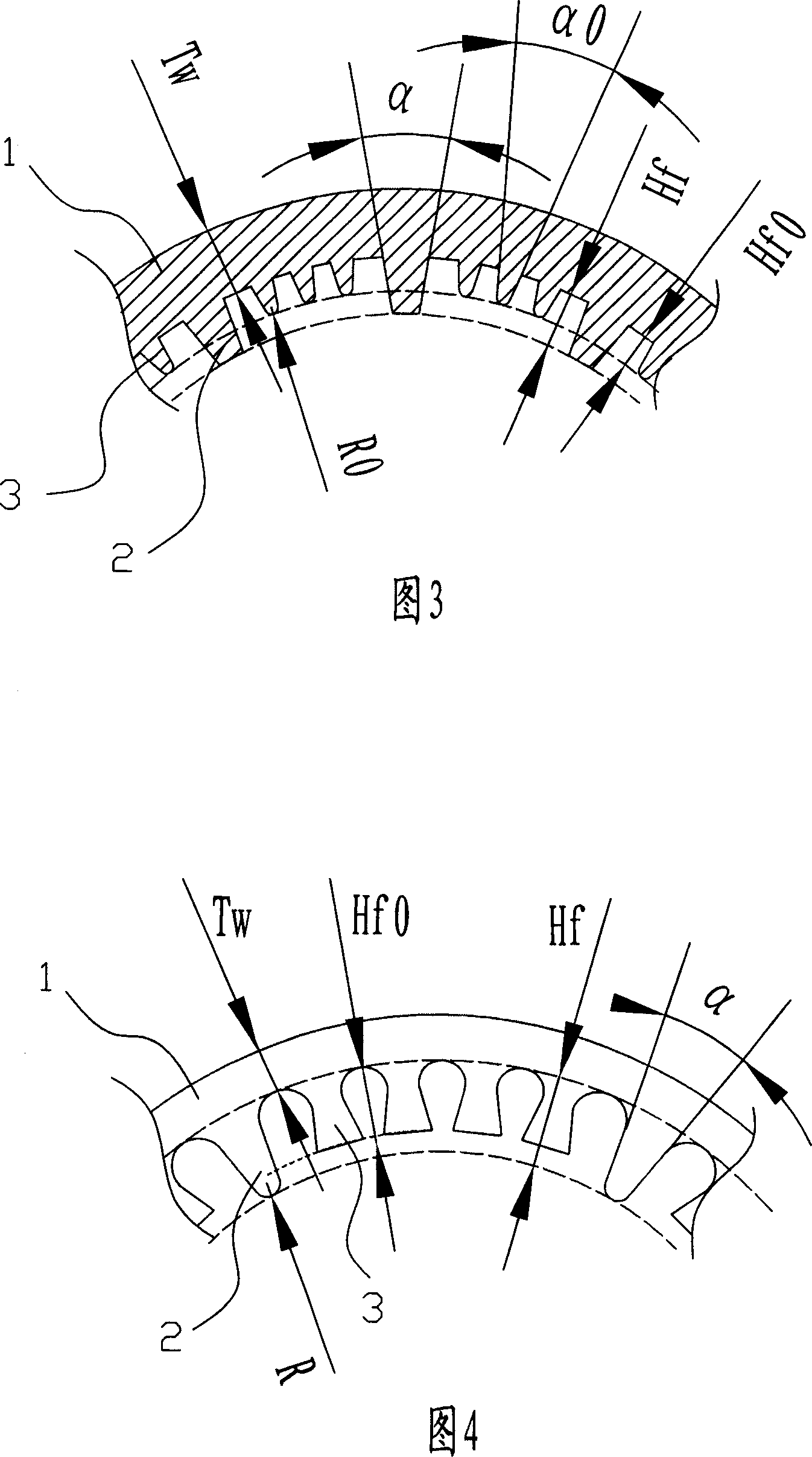

[0020] The structure of a preferred embodiment of the present invention is shown in Figures 1 and 2. The internally threaded heat transfer tube 1 made of aluminum or aluminum alloy material has an outer diameter D of 10 millimeters (hereinafter abbreviated as mm). According to different use and production needs, considering the different characteristics of the extrusion molding process and the spinning forming process, the outer diameter D of the heat transfer tube can also be 3 to 16 mm, and the preferred value of the extrusion molding is 4 to 10 mm. The preferred value for spinning forming is 5-16 mm. The inner surface of the internally threaded heat transfer tube 1 is provided with a plurality of tooth ribs parallel to each other, and the tooth ribs include high teeth 2 and low teeth 3 arranged at intervals, and the interval between the two adjacent high teeth 2 is 1 to 5 A low tooth 3, is 3 in the present embodiment. The high teeth are the tube expansion teeth used to sup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Addendum angle | aaaaa | aaaaa |

| Tooth height | aaaaa | aaaaa |

| Addendum angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com