Pipe heat exchanger

A tubular heat exchanger and heat exchanger technology, applied in the field of heat exchange devices, can solve the problems of reduced heat transfer coefficient, increased use cost, hindering heat exchange between high-temperature fluid and low-temperature fluid, etc., to improve heat transfer coefficient, The effect is good and the production cost is saved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

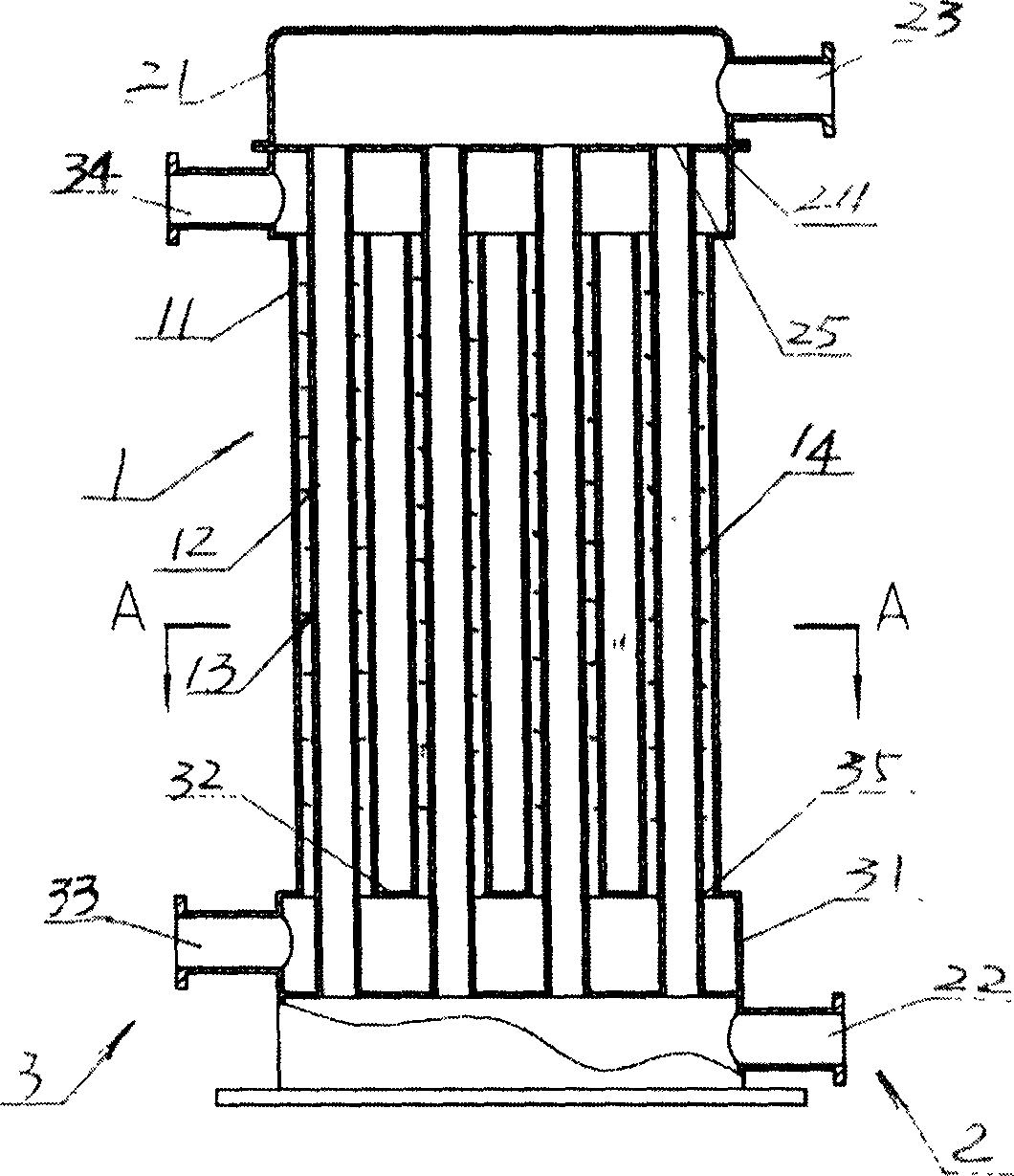

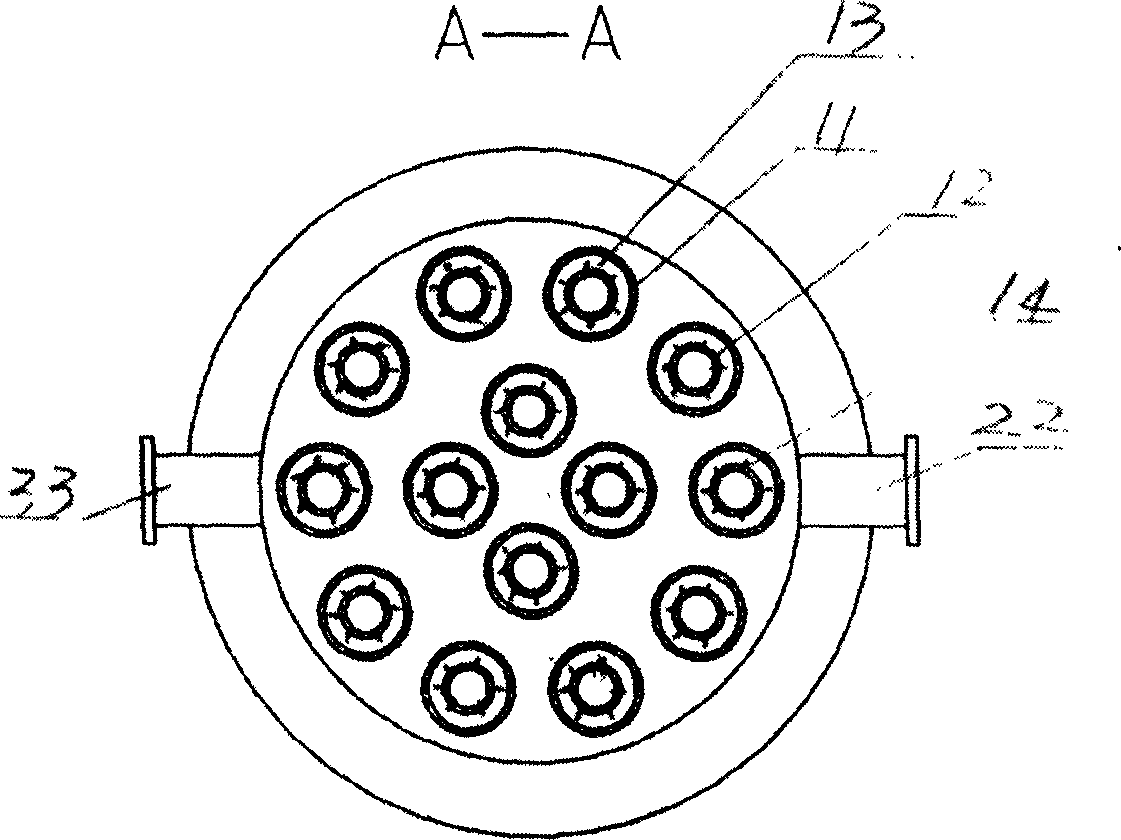

[0010] See attached figure 1 And attached figure 2 , these two drawings show the overall structure of the appearance of an embodiment of the tube heat exchanger proposed by the present invention. As can be seen from the accompanying drawings, the heat exchanger includes two parts: the casing group 1 and the header group.

[0011] The sleeve group 1 is a sleeve bundle composed of multiple sleeves, each of which has an outer tube 11 and an inner tube 12 inserted into the outer tube 11 and provided with rows of protrusions 14 around its periphery, The protrusion 14 can increase the heat dissipation area of the inner tube 12 , both ends of the inner tube 12 extend beyond the two ends of the outer tube 11 , and there is a certain distance 13 between the outer wall of the inner tube 12 and the inner wall of the outer tube 11 . When the high-temperature fluid is oil, the distance 13 can be designed to be relatively small, and when the high-temperature fluid is gas, the distance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com