T cell type reinforced heat exchanging tube

A technology of heat exchange tubes and small cells, which is applied in the direction of tubular elements, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of reducing the flow area and increasing resistance, so as to increase the degree of turbulence and improve the heat transfer coefficient of the tube side , enhance the effect of heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

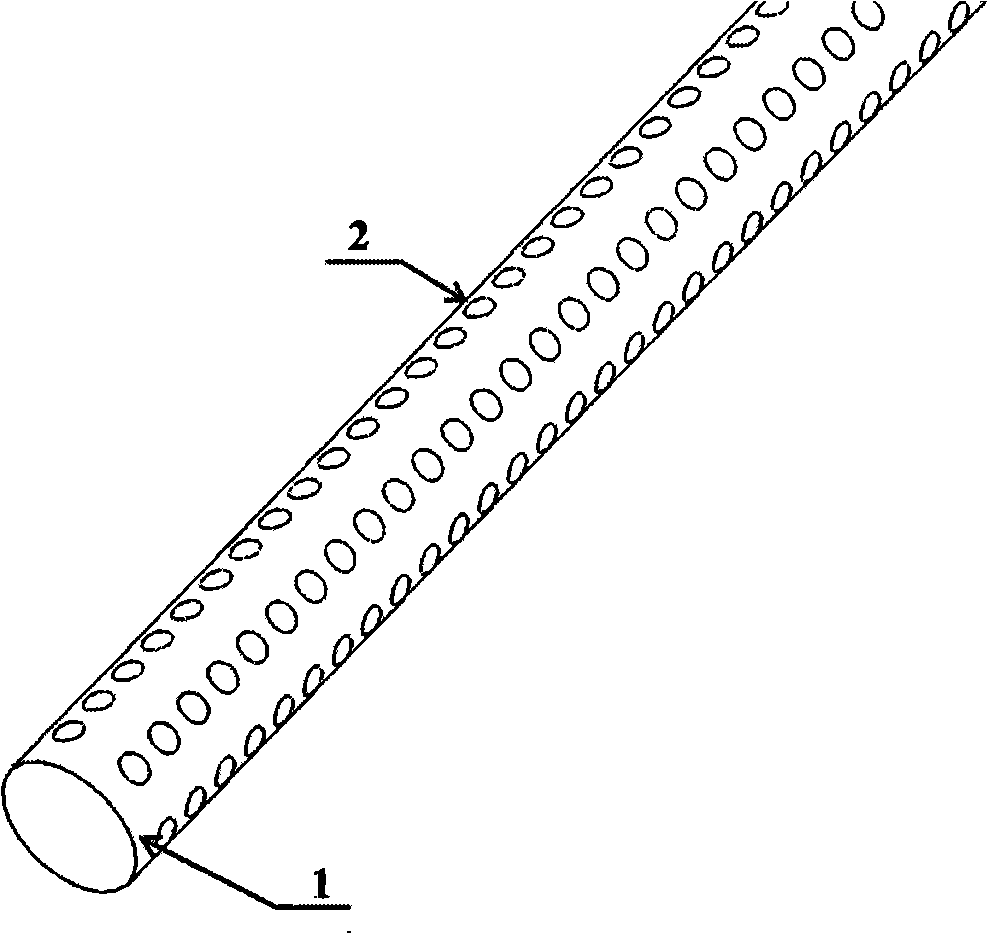

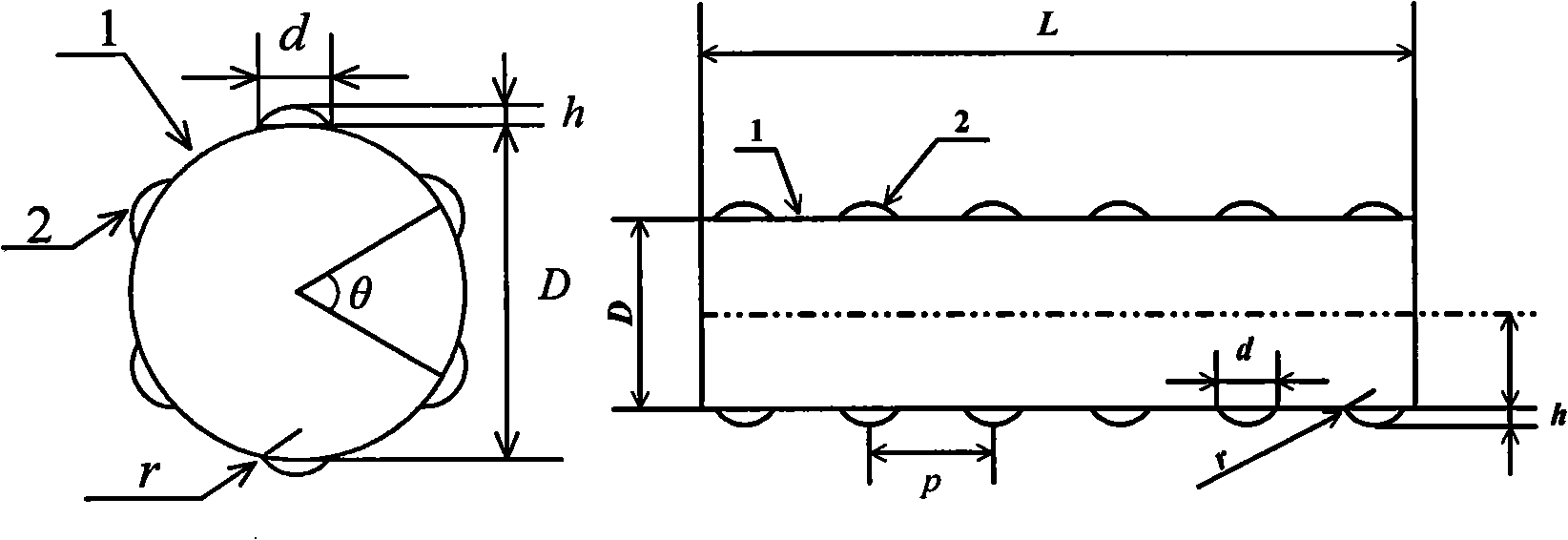

[0013] Example 1, see figure 1 , 2, the present invention includes the base tube 1 and the base tube 1 circumferentially evenly distributed by the base tube 1 The inner wall of the spherical crown tetracystis 2 is formed of the spherical crown tetracystis 2, and several dicytic groups flow along the base tube 1 The directions are evenly distributed, the cross-section of the base tube 1 at the D-cell is plum-shaped, and the other cross-sections are circular; due to the existence of the D-cell, the flow channel is a periodic concave-convex channel, where "L" is the tube length of the base tube 1 , "D" is the diameter of the base tube 1; the height h of the protuberance of the tetracyte is 0.1-1 mm; the radius r of the spherical crown of the tetracyte is 0.5-2.5 mm; The angle θ is 10°~120°, and the distance p between the groups of cells in the flow direction is 1mm~10mm.

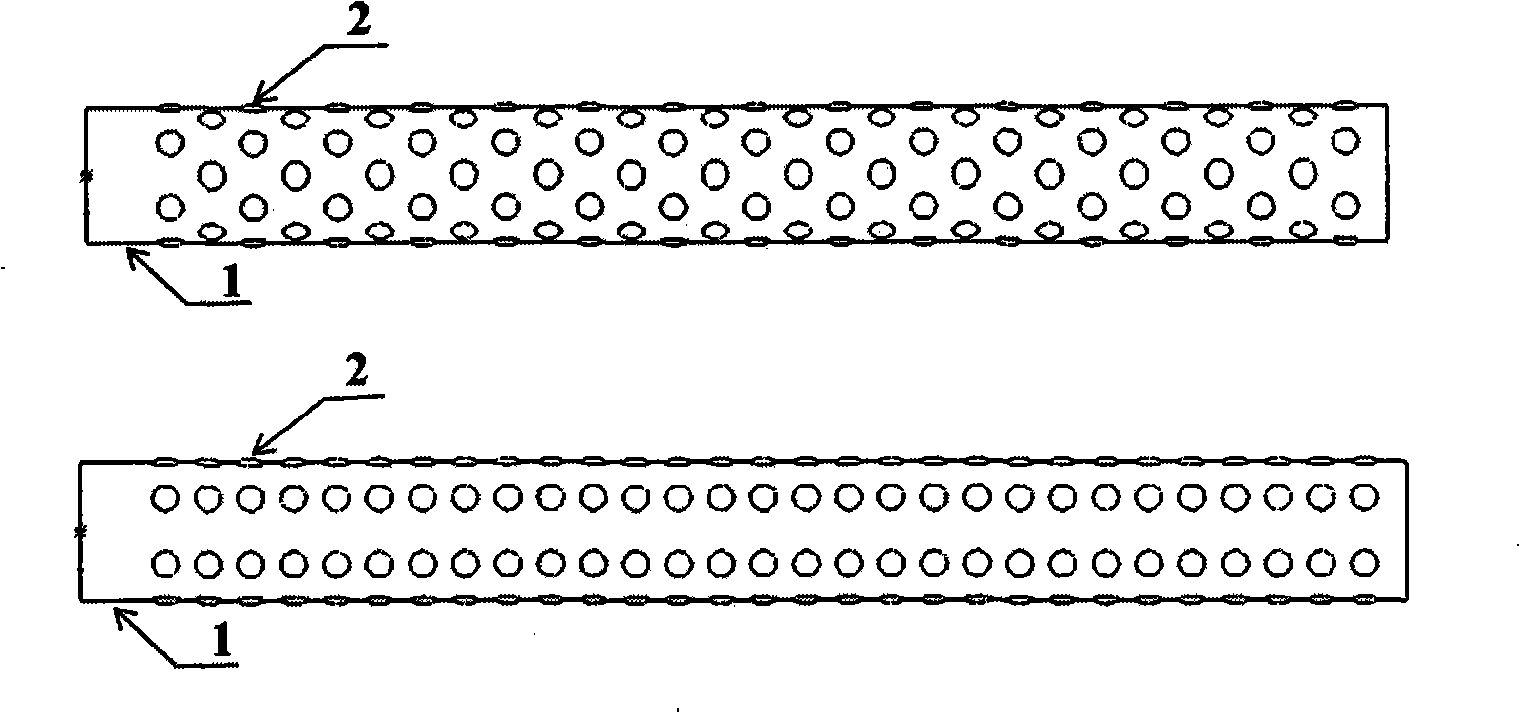

[0014] see image 3 , image 3 There are two different arrangements of D-cell heat exchange tubes, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com