Equal-interval ring type motor cooling water channel

A technology for motor cooling and cooling water channels, applied in cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve problems such as unsatisfactory cooling effect, motor failure, and inability to form turbulent water channels, so as to improve heat transfer coefficient and exchange rate. Effect of heat rate, reduction of temperature rise, and improvement of machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

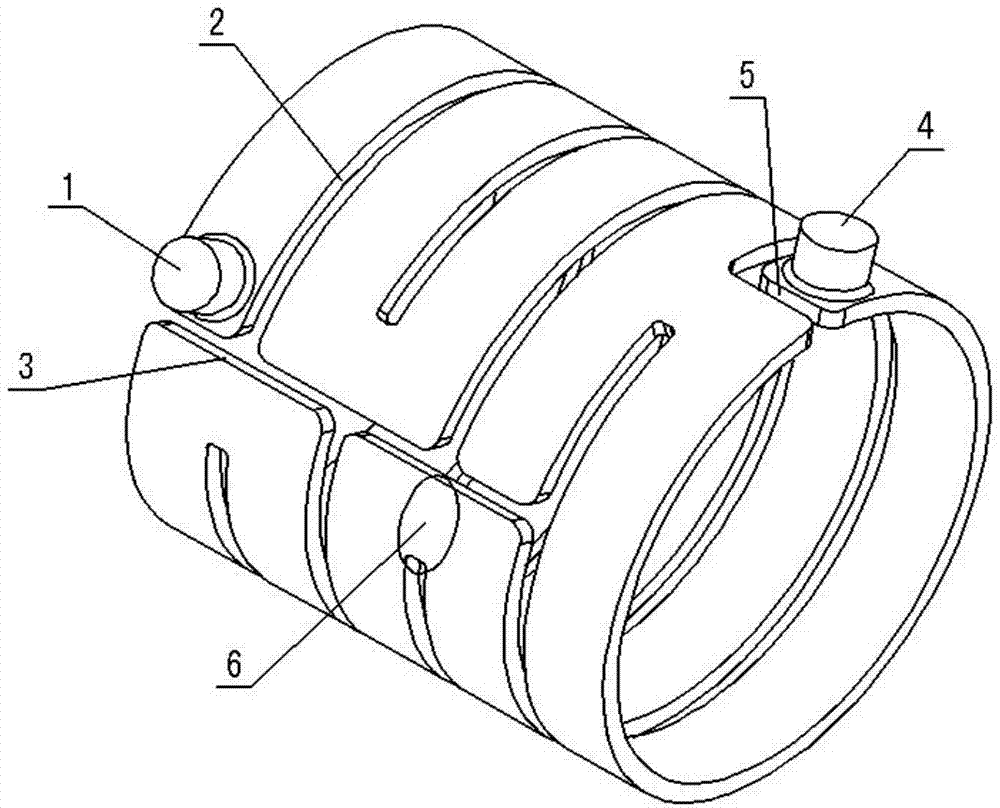

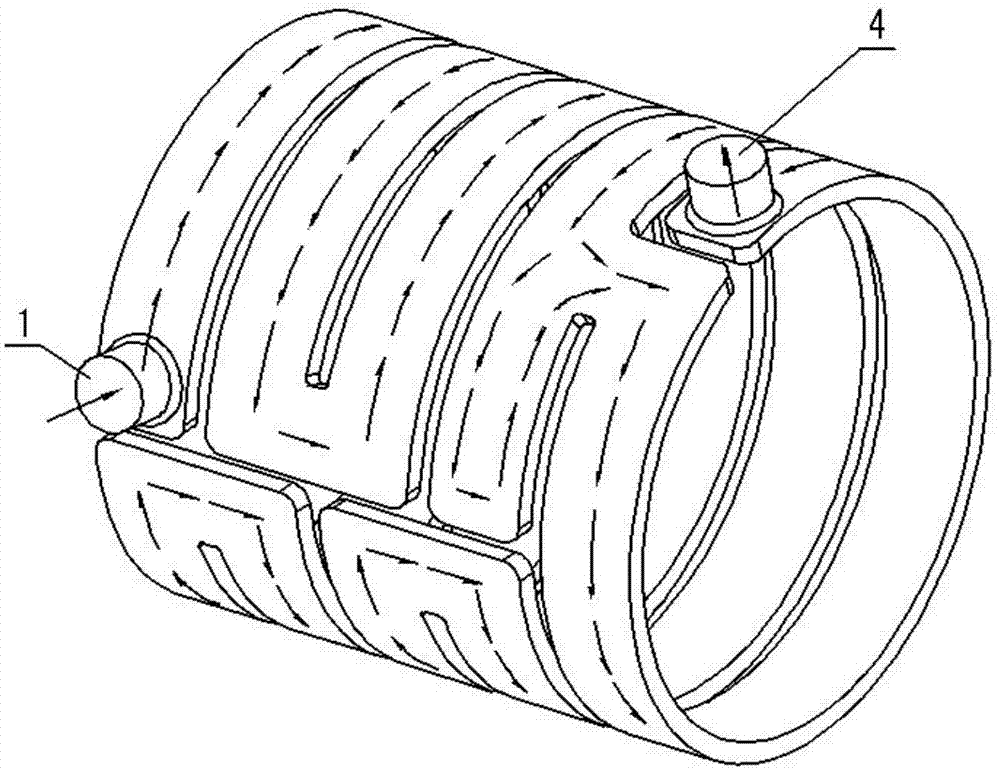

[0019] see figure 1 , figure 2 and image 3 , the structural form of the equidistant ring form motor cooling channel in this embodiment is:

[0020] The cooling water channel is connected to a continuous water flow channel by the annular cavities equidistant and spaced along the axial direction. The cooling water inlet 1 and the cooling water outlet 4 of the water flow channel are located at the water inlet end ring and the cooling water outlet at the two ends. On the water outlet ring; each annular chamber is an open ring that can be flattened into a rectangle; adjacent annular chambers are connected end to end, and end to end connection means that the outlet of the adjacent previous annular chamber is connected with the entrance of the next annular chamber. In order to make the circumferential direction of the water flow formed in the adjacent annular cavity around the surface of the motor casing opposite.

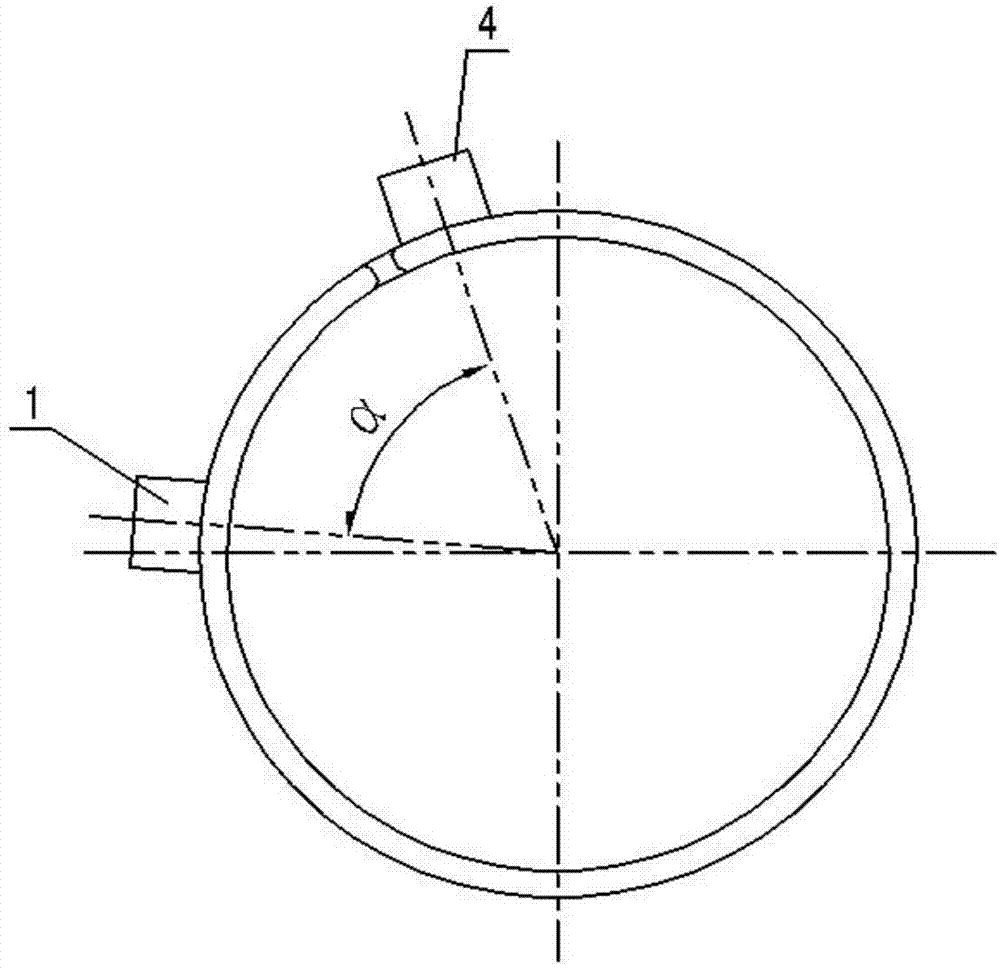

[0021] In the specific implementation, the angle between the ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com