Method and device for testing heat exchange coefficients of steel plate with different water film thickness

A heat transfer coefficient and water film thickness technology, applied in the field of hot rolling cooling, can solve the problem of not testing the heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

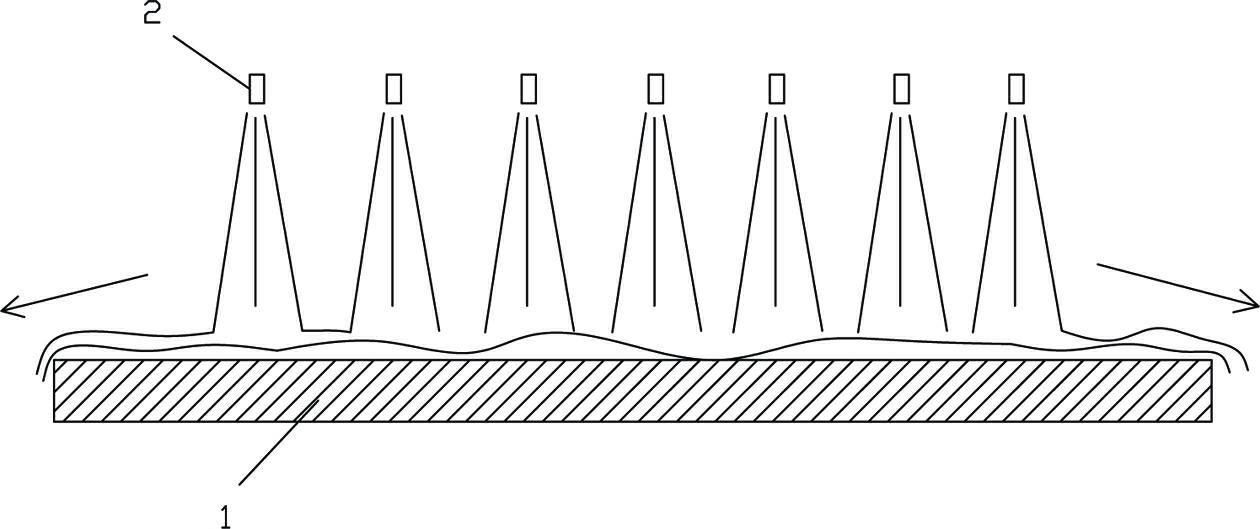

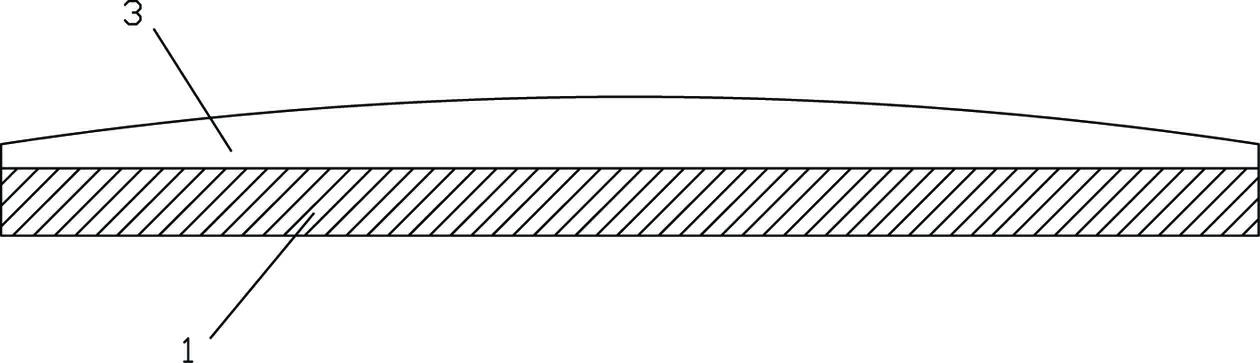

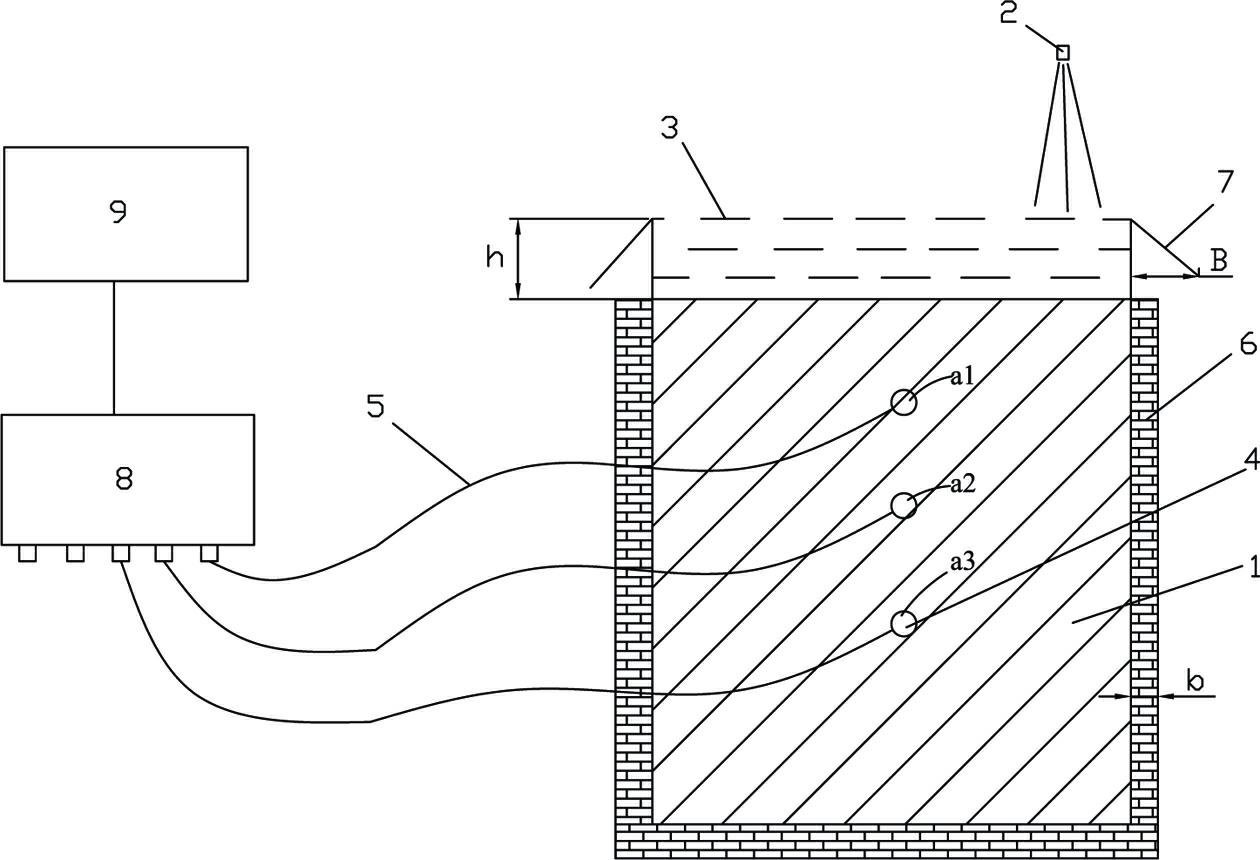

[0067] see Figure 1 to Figure 5 In the present invention, a cylindrical steel sample with a thickness of 145 mm and a radius of 20 mm is used to drill embedded couple holes 4 at the positions of 10 mm (a1), 30 mm (a2), and 50 mm (a3) from the surface, and three K-type thermoelectric tubes are embedded. Couple 5, thermocouple temperature range 0 ~ 1000 ℃, sampling frequency is 5. After the steel plate was heated to 900°C, it was taken out and sprayed with water for cooling, and the temperature data of the cooling process was recorded. The temperature acquisition device uses a multi-channel temperature recorder 8 and a data memory 9 .

[0068] The density of the steel sample is 7850kg / m 3 , the specific heat is 673.9J / (kg*K), the thermal conductivity is 31J / (s*m*K), and the water temperature Tw is 25°C. The height h of the water film cofferdam is 10mm, the length B of the water retaining plate is 50mm, and the thickness of the insulation layer b is 40mm.

[0069] At the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com