Fully automatic air cooling semi-solid pulping machine

A semi-solid, pulping machine technology, applied in the field of casting, can solve the problems of difficult product quality assurance, cumbersome control operation, low production efficiency, etc., and achieve the effects of accurate cooling control, cost reduction and production efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

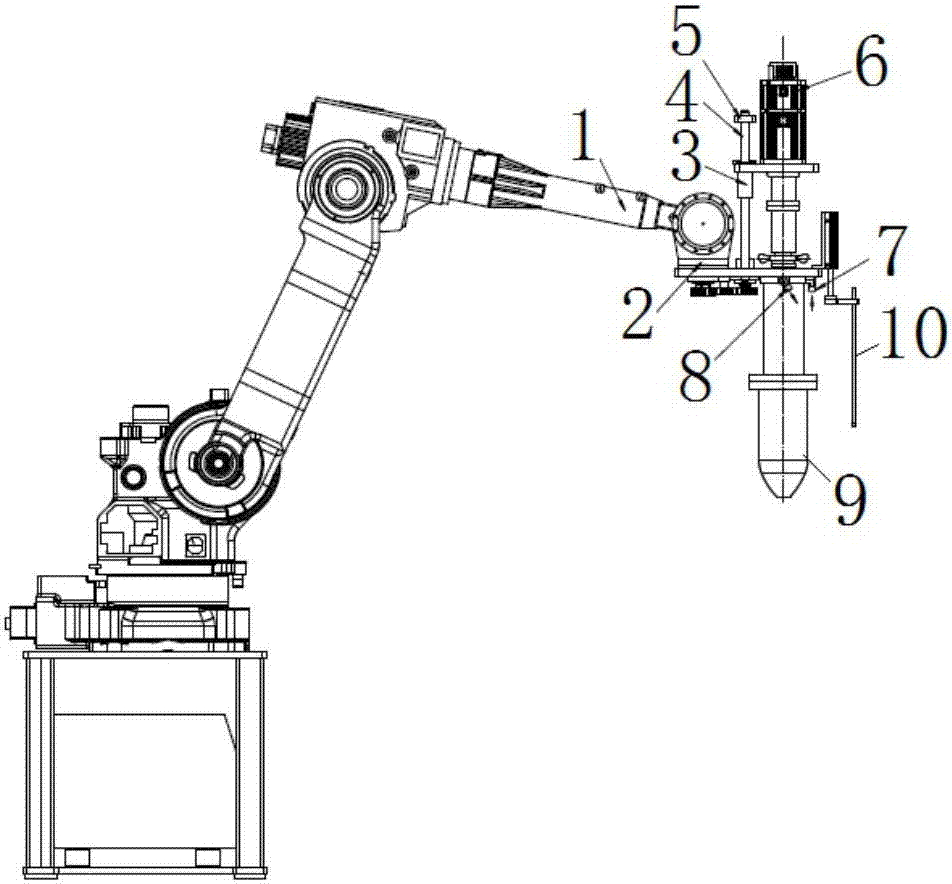

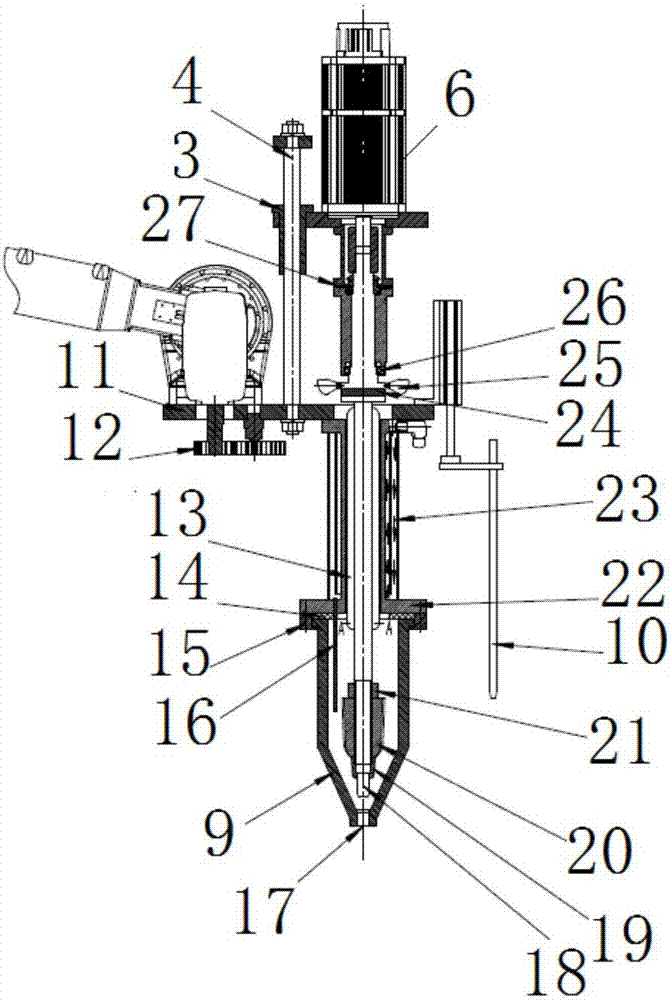

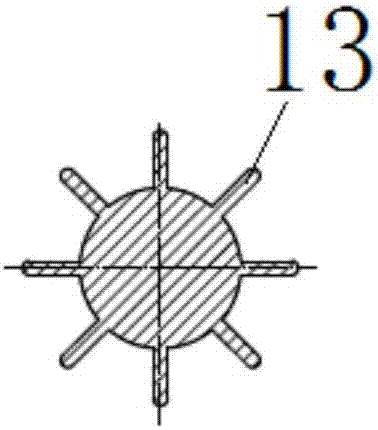

[0030] Such as Figure 1 to Figure 3 As shown, the fully automatic air-cooled semi-solid pulping machine includes a mechanical arm 1, a liquid-taking barrel 9, a motor 6, a main shaft, a liquid level sensor 10, a temperature sensor 16, and a connecting flange 22, wherein the mechanical arm 1 is The arm of the industrial robot, the support plate 11 is fixed on the mechanical arm, and the liquid-taking material cylinder 9 is fixed on the support plate 11 through the connecting flange 22, which can move together with the mechanical arm. The barrel mouth enters the liquid and the casting liquid exits.

[0031] Motor 6 is a servo motor, and the motor is used to drive the main shaft to rotate. The lower part of the main shaft is located in the liquid-taking barrel, and the main shaft located in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com