Optimal parameter determination method for plate-fin evaporator

An evaporator and plate-fin technology, which is applied in the field of determining the optimization parameters of plate-fin evaporators, can solve the problems that the reliability and safety of electronic equipment cannot be fully guaranteed, and the heat generation of electronic equipment cannot be satisfied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

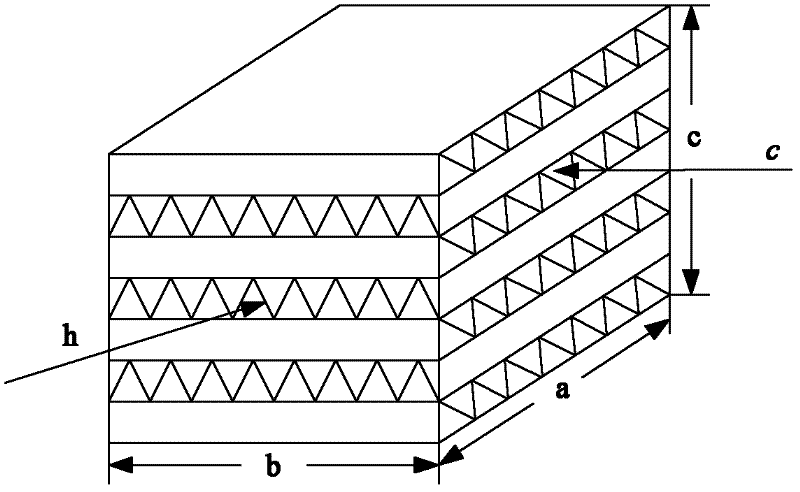

[0014] The design methods in the prior art are mainly suitable for heat exchangers with gas flow, and with the development of industry, compact heat exchangers such as plate-fin heat exchangers are no longer limited to the flow of single-phase gas, but more and more The more it is used as evaporator and condenser, that is, the heat exchange of two-phase fluid, so this method is improved on the basis of the gas compact heat exchanger design method, and a plate suitable for two-phase flow heat exchange is proposed Method for determining the parameters of finned evaporators.

[0015] Determination of parameters in a plate-fin evaporator suitable for two-phase flow heat exchange according to an embodiment of the present invention

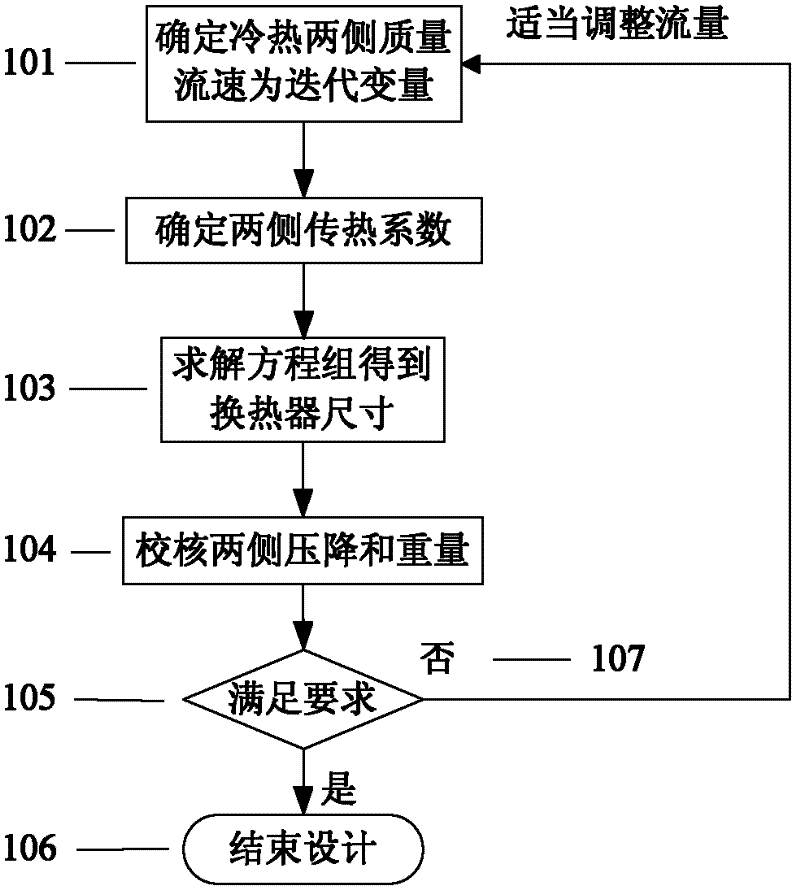

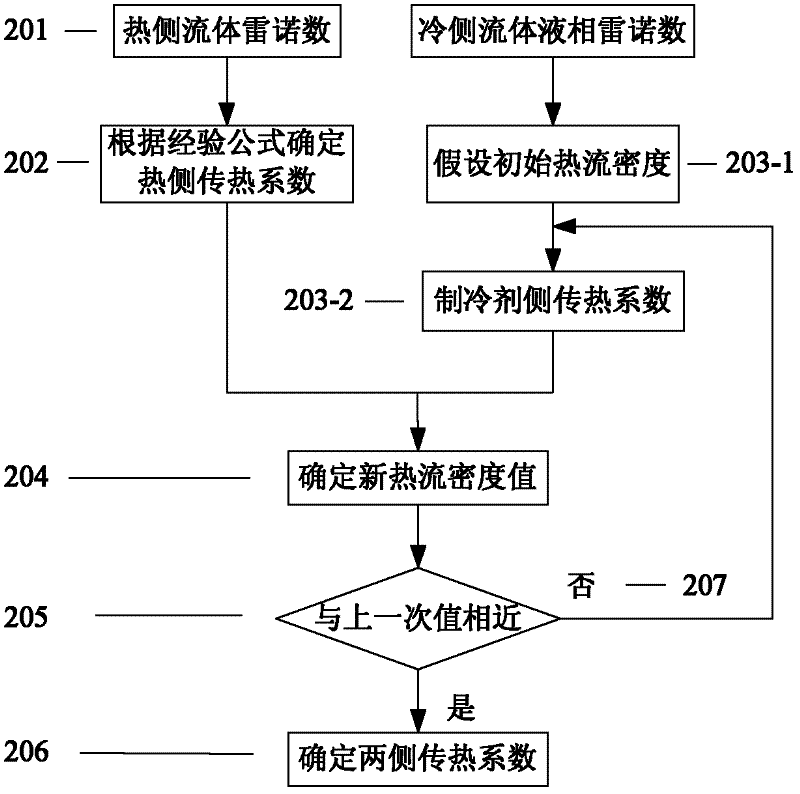

[0016] In the method, the mathematical model of the plate-fin evaporator that can meet the pressure drop and efficiency requirements at the same time is determined first, and its

[0017] Including:

[0018] - Neglect the thermal resistance of the col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com