High-density oil-based drilling fluid and preparation method thereof

An oil-based drilling fluid and high-density technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of high-density oil-based drilling fluid that is easy to change, and has a great influence on the stability of the wellbore wall in high-pressure formations. The composition and preparation of emulsifiers are complicated to achieve the effect of improving the balance of hydrophilic and lipophilic, improving the stability of emulsification and good emulsification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

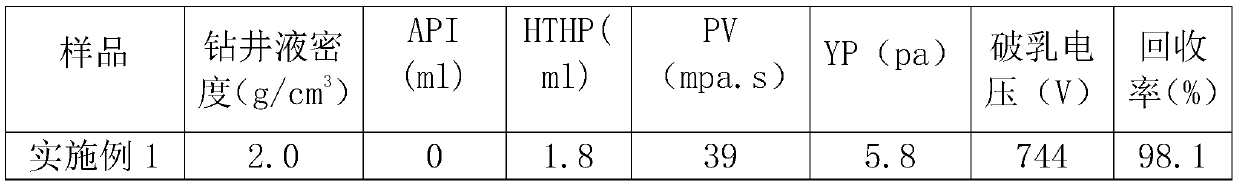

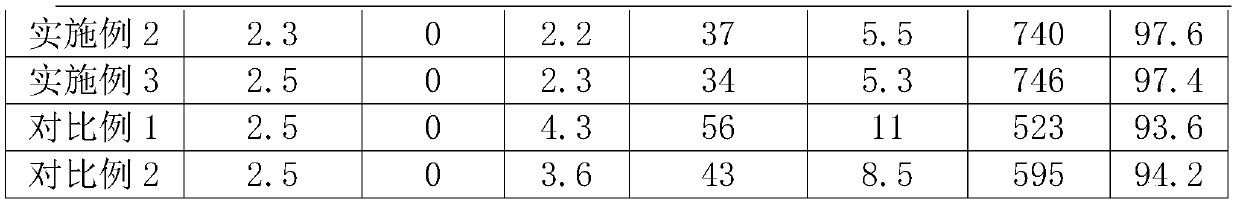

Examples

Embodiment 1

[0017] A high-density oil-based drilling fluid, comprising the following components in parts by weight: 80 parts of diesel oil, 2 parts of main emulsifier, 1 part of auxiliary emulsifier, 1 part of organic bentonite, 2 parts of calcium oxide, 3 parts of asphalt, mass 20 parts of calcium chloride aqueous solution with a fraction of 25 and barite powder, the main emulsifier is composed of 7 parts of higher fatty acid diethylenetriamine, 3 parts of maleic polyamide, and 1 part of polyoxyethylene ether. The emulsifier is sodium dodecylbenzenesulfonate, and the barite powder increases the density of the drilling fluid to 2.0g / cm 3 .

[0018] The preparation method of the high-density oil-based drilling fluid is as follows: add diesel oil into the mixing cup, then add the main emulsifier, auxiliary emulsifier, organic bentonite, calcium oxide, asphalt, and a mass fraction of 25-35% calcium chloride aqueous solution, finally adding barite powder to increase the density of the drilli...

Embodiment 2

[0020] A high-density oil-based drilling fluid, comprising the following components in parts by weight: 85 parts of white oil, 4 parts of main emulsifier, 3 parts of auxiliary emulsifier, 1.5 parts of organic bentonite, 2.5 parts of sodium hydroxide, modified lignite 4 parts of resin, mass fraction are 15 parts of calcium chloride aqueous solution and barite powder of 30%, and described main emulsifier is made of 7.5 parts of higher fatty acid fat diethylene triamine, 4 parts of maleic polyamide, polyoxyethylene ether 2 The co-emulsifier is sodium dodecylbenzenesulfonate, and the barite powder increases the density of the drilling fluid to 2.3g / cm 3 .

[0021] The preparation method of the high-density oil-based drilling fluid is as follows: add white oil into a mixing cup, and then add the main emulsifier, auxiliary emulsifier, organic bentonite, sodium hydroxide, and modified lignite under the stirring of a high-speed mixer. Resin, calcium chloride aqueous solution with a m...

Embodiment 3

[0023] A high-density oil-based drilling fluid, comprising the following components in parts by weight: 90 parts of diesel oil, 4 parts of primary emulsifier, 0.5 part of secondary emulsifier, 1.5 parts of organic bentonite, 3 parts of calcium hydroxide, 5 parts of asphalt, Mass fraction is 10 parts of calcium chloride aqueous solution of 35% and weighting agent, and described main emulsifier is made up of 8 parts of higher fatty acid ester diethylenetriamine, 5 parts of maleic polyamide, 3 parts of polyoxyethylene ether, described The auxiliary emulsifier is sodium dodecylbenzene sulfonate; the weighting agent is a mixture of barite powder and iron ore powder, and the weighting agent increases the density of drilling fluid to 2.5g / cm 3 .

[0024] The preparation method of the high-density oil-based drilling fluid is as follows: adding diesel oil into the mixing cup, and then adding the main emulsifier, auxiliary emulsifier, organic bentonite, calcium hydroxide, asphalt, mass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com