Foam scrubbing defoaming agent for developing normal-pressure shale gas and preparation method of foam scrubbing defoaming agent

A technology of shale gas and defoaming agent, applied in the field of shale gas, can solve the problems of difficult defoaming agent and difference in defoaming ability of foaming agent, achieve high foam suppression ability, improve permeability and diffusivity, shorten The effect of bubble break time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

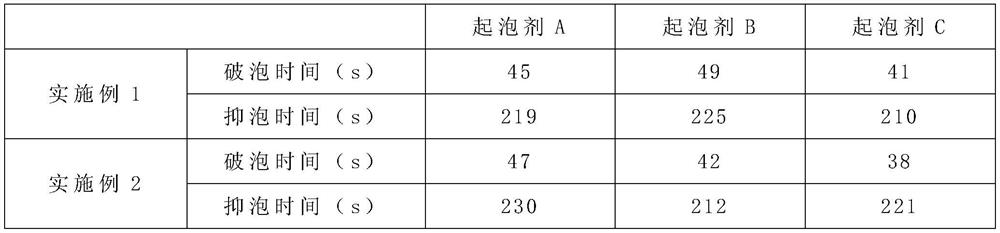

Embodiment 1

[0028] A foam row defoamer for normal pressure shale gas development, comprising the following components by weight in kg:

[0029] Silicone oil I 45kg, silicone oil II 15kg, silicone oil III 3kg, emulsifier 12kg, n-propanol 4kg, ascorbic acid 5kg, water 16kg;

[0030] At room temperature of 25°C, the viscosity of silicone oil I is 5cps, the viscosity of silicone oil II is 500cps, and the viscosity of silicone oil III is 5000cps;

[0031] The emulsifier is composed of polyvinyl ethers and lecithin, and the weight ratio of polyvinyl ethers and lecithin is 4:1. The preparation method of the above-mentioned atmospheric pressure shale gas development foam row defoamer, the process is as follows:

[0032] (1) Add silicone oil Ⅰ, silicone oil Ⅱ and silicone oil Ⅲ into the stirring tank, mix well, then add emulsifier into it, continue stirring well to obtain mixed solution Ⅰ, control the stirring speed to 350r / min;

[0033] (2) Add ascorbic acid into water, stir until dissolved, th...

Embodiment 2

[0036] A foam row defoamer for normal pressure shale gas development, comprising the following components by weight in kg:

[0037] Silicone oil I 40kg, silicone oil II 10kg, silicone oil III 1kg, emulsifier 10kg, n-propanol 2kg, ascorbic acid 2kg, water 35kg;

[0038] Among them, at a room temperature of 25°C, the viscosity of silicone oil I is 5cps; the viscosity of silicone oil II is 400cps; the viscosity of silicone oil III is 5000cps;

[0039] The emulsifier is composed of polyvinyl ethers and lecithin, and the weight ratio of polyvinyl ethers and lecithin is 3:1. The preparation method of the above-mentioned atmospheric pressure shale gas development foam row defoamer, the process is as follows:

[0040] (1) Add silicone oil Ⅰ, silicone oil Ⅱ and silicone oil Ⅲ into the mixing tank, mix well, then add emulsifier into it, control the stirring speed to 300r / min, and continue stirring to obtain mixed solution Ⅰ;

[0041] (2) Add ascorbic acid into water, stir until dissol...

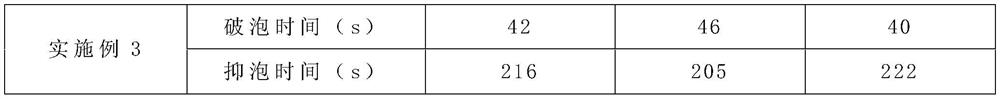

Embodiment 3

[0044] A foam row defoamer for normal pressure shale gas development, comprising the following components by weight in kg:

[0045] Silicone oil I 50kg, silicone oil II 15kg, silicone oil III 5kg, emulsifier 15kg, n-propanol 5kg, ascorbic acid 3kg, water 7kg;

[0046] Among them, the viscosity of silicone oil I is 10cps at room temperature of 25°C; the viscosity of silicone oil II is 600cps; the viscosity of silicone oil III is 6000cps.

[0047] The emulsifier is composed of polyvinyl ethers and lecithin, and the weight ratio of polyvinyl ethers and lecithin is 5:1.

[0048] The preparation method of the above-mentioned atmospheric pressure shale gas development foam row defoamer, the process is as follows:

[0049] (1) Add silicone oil Ⅰ, silicone oil Ⅱ and silicone oil Ⅲ into the mixing tank, mix well, then add emulsifier into it, control the stirring speed to 400r / min, and continue stirring to obtain the mixed solution Ⅰ;

[0050] (2) Add ascorbic acid into water, stir un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com