Reservoir transformation method and application of normal-pressure shale gas horizontal well

A shale gas well and reservoir reconstruction technology, which is applied in earthwork drilling, wellbore/well components, production fluids, etc., can solve problems such as low fracturing fluid flowback rate, low pressure coefficient, and reservoir damage, and achieve Solve the problem of incomplete gel breaking, improve fracturing effect, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Horizontal well A drilled high-quality shale sections from Upper Ordovician Wufeng Formation to Lower Silurian Longmaxi Formation. The lithology is black organic-rich siliceous shale. The measured depth is 4263-3041m. The horizontal section is 1222m long and divided into 17 sections. , segment length is 49-110m (average 78m), 2-4 cluster perforations, brittle mineral content is 66.63% (54.29-74.28), silicon content is 57.6% (40.23-69.95), clay content is 22.74% (18.09-33.76 ), bedding fractures are widely developed, and the overlying rock static pressure is 72.2MPa (71.79-72.5MPa).

[0047] Through the on-site micro-injection test, the measured vertical depth in the middle of the horizontal section is 3182.67m, the static pressure is 34.68MPa, the formation pressure coefficient is 1.08, and the temperature is 80°C. The test results show that the shale in this well area is a normal pressure reservoir.

[0048] In order to evaluate the production capacity of the target sh...

Embodiment 2

[0098] Theoretical model verification:

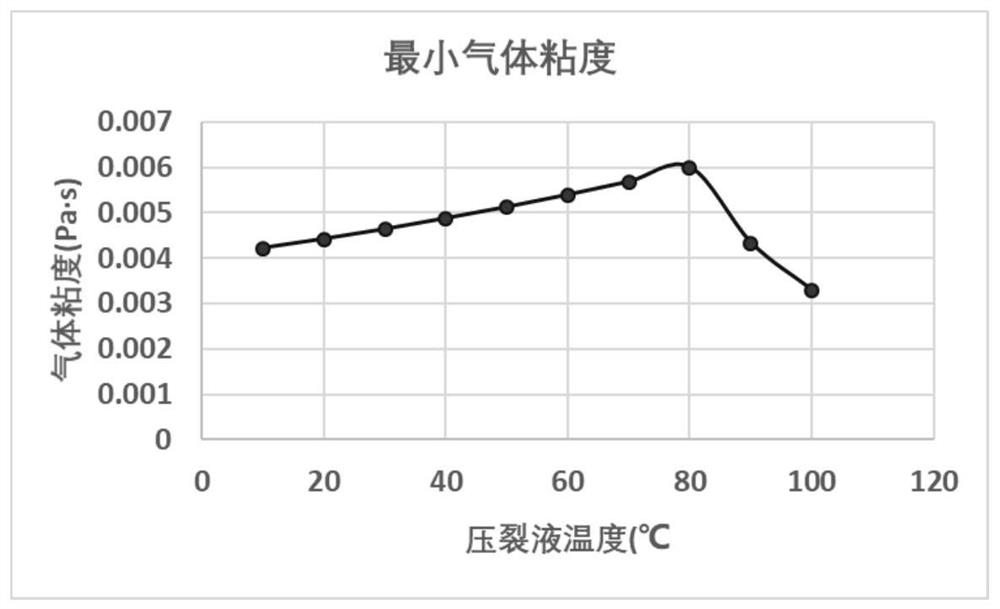

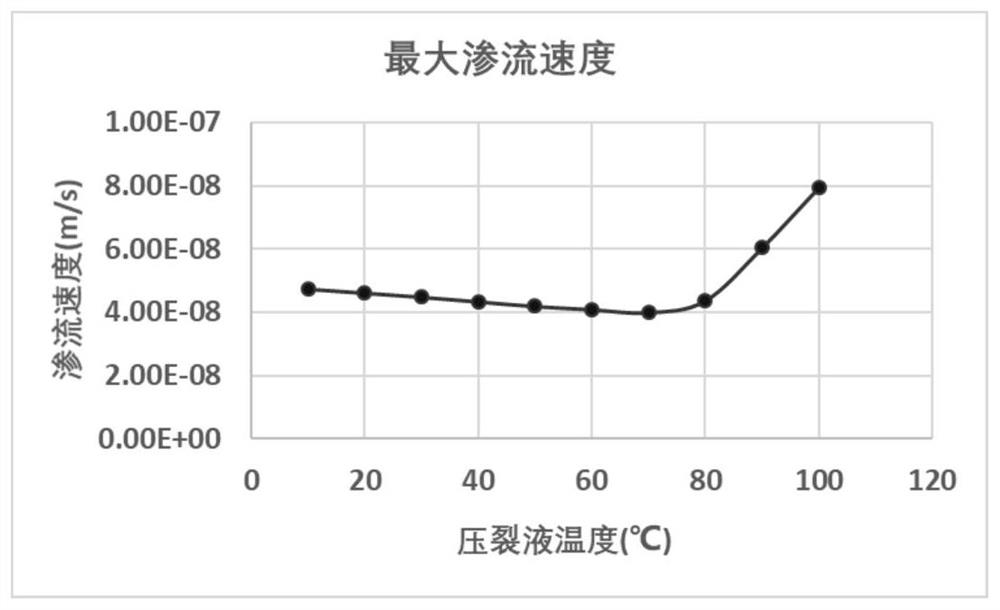

[0099] Based on the comsol multiphysics software platform, this study established a two-dimensional heat transfer-shale gas seepage numerical model in shale reservoirs, taking into account both free gas and adsorbed gas, and considering the dynamic adsorption capacity of shale for methane under different temperature conditions and The difference in methane viscosity was used to quantitatively evaluate the effect of hot slick water on improving shale gas production performance.

[0100] Simulation results show that:

[0101] (1) Assuming that the original reservoir temperature of A shale gas horizontal well is 80°C, if slick water at normal surface temperature of 20°C is used for fracturing, the numerical simulation results show that the minimum temperature near the wellbore will drop to 46°C after one day of operation, and the intersection of cold and heat Advance 125m from the wellbore to the far end along the artificial fracture.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com