Foam drainage foaming agent for normal-pressure shale gas development and preparation method thereof

A foam drainage and shale gas technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as poor salt resistance of foaming agents, achieve enhanced foam stabilization performance, enhanced liquid carrying capacity, and enhanced stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

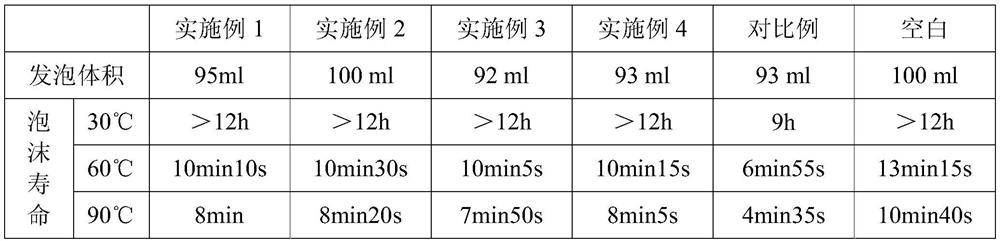

Examples

Embodiment 1

[0019] A foam drainage foaming agent for normal pressure shale gas development, comprising the following components in parts by weight: sodium dodecylsulfonate 4g, sodium dodecylbenzenesulfonate 1g, nonylphenol polyoxyethylene ether 2g , polyvinyl alcohol 3g, Tween 80 4g, EDTA 2g, triethanolamine 5g (viscosity is 590cP, 25°C), ammonium carbonate 7g, water 72g.

[0020] The preparation method is: add water to the reaction kettle, control the temperature at 20-30°C, add 5g of triethanolamine under stirring, and then add 4g of sodium dodecylsulfonate, 1g of sodium dodecylbenzenesulfonate, poly Dissolve 3g of vinyl alcohol and 7g of ammonium carbonate, add 4g of Tween 80, 2g of EDTA and 2g of nonylphenol polyoxyethylene ether after dissolving, stir evenly and let stand to obtain a foam drainage foaming agent for shale gas development at normal pressure.

Embodiment 2

[0022] A foam drainage foaming agent for normal pressure shale gas development, comprising the following components in parts by weight: sodium dodecylsulfonate 5g, sodium dodecylbenzenesulfonate 2g, nonylphenol polyoxyethylene ether 1g , 0.5 g of octylphenol polyoxyethylene ether, 3 g of polyvinyl alcohol, 5 g of Tween 80, 2 g of EDTA, 5 g of triethanolamine (viscosity of 590 cP, 25° C.), 8 g of ammonium carbonate, and 68 g of water.

[0023] The preparation method is as follows: add water to the reaction kettle, control the temperature at 20-30°C, add 5g of triethanolamine under stirring, and then add 5g of sodium dodecylsulfonate, 2g of sodium dodecylbenzenesulfonate, poly Vinyl alcohol 3g and ammonium carbonate 7g, after dissolving, add Tween 80 5g, EDTA 2g, nonylphenol polyoxyethylene ether 1g and octylphenol polyoxyethylene ether 0.5g, stir evenly and let stand to obtain normal pressure shale gas Development of blowing agents for foam drainage.

Embodiment 3

[0025] A foam drainage foaming agent for normal pressure shale gas development, comprising the following components in parts by weight: sodium dodecylsulfonate 7g, sodium dodecylbenzenesulfonate 1g, octylphenol polyoxyethylene ether 1g , polyvinyl alcohol 3g, Tween 80 4g, EDTA 2g, triethanolamine 6g (viscosity is 590cP, 25°C), ammonium bicarbonate 5g, water 71g.

[0026] The preparation method is as follows: add water to the reaction kettle, control the temperature at 20-30°C, add 6g of triethanolamine under stirring, and then add 7g of sodium dodecylsulfonate, 1g of sodium dodecylbenzenesulfonate, poly Vinyl alcohol 3g and ammonium bicarbonate 5g, after dissolving, add 4g of Tween 80, 2g of EDTA and 1g of octylphenol polyoxyethylene ether, stir evenly and let it stand still to obtain a foam drainage foaming agent for shale gas development under normal pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com