Integrated normal-pressure shale gas drainage gas recovery and on-site treatment device

A drainage gas recovery and on-site treatment technology, which is applied in the fields of fluid extraction, earth drilling, gas/liquid distribution and storage, etc. It can solve problems such as poor purity of shale gas collection, blockage of filter mechanism, time-consuming and laborious disassembly and removal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

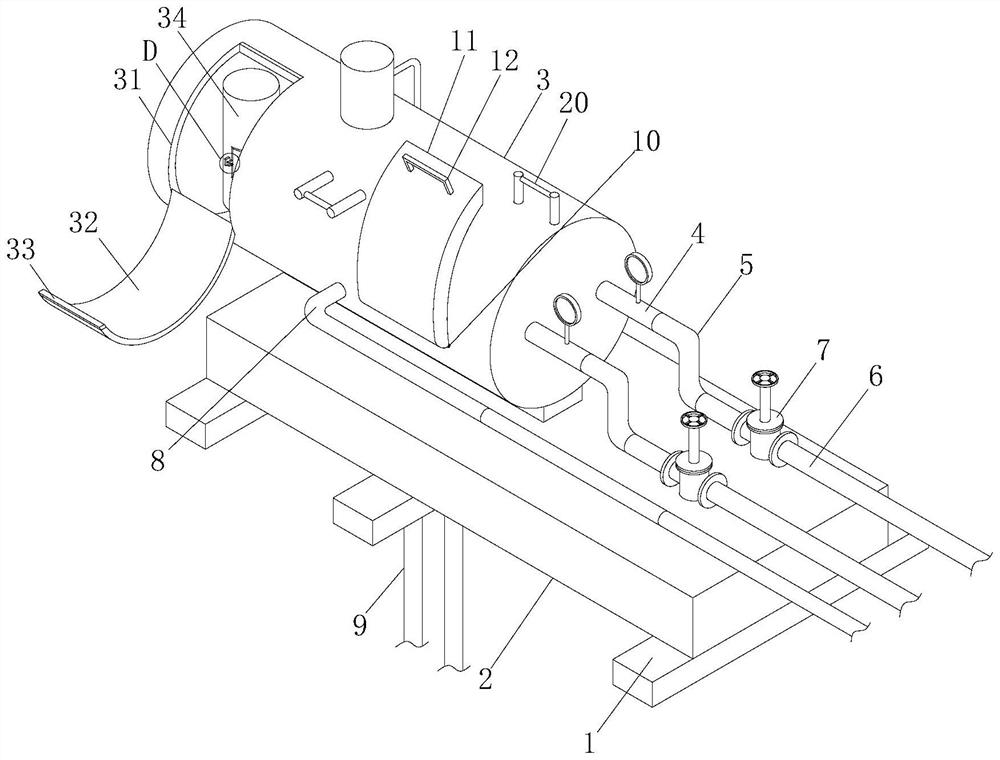

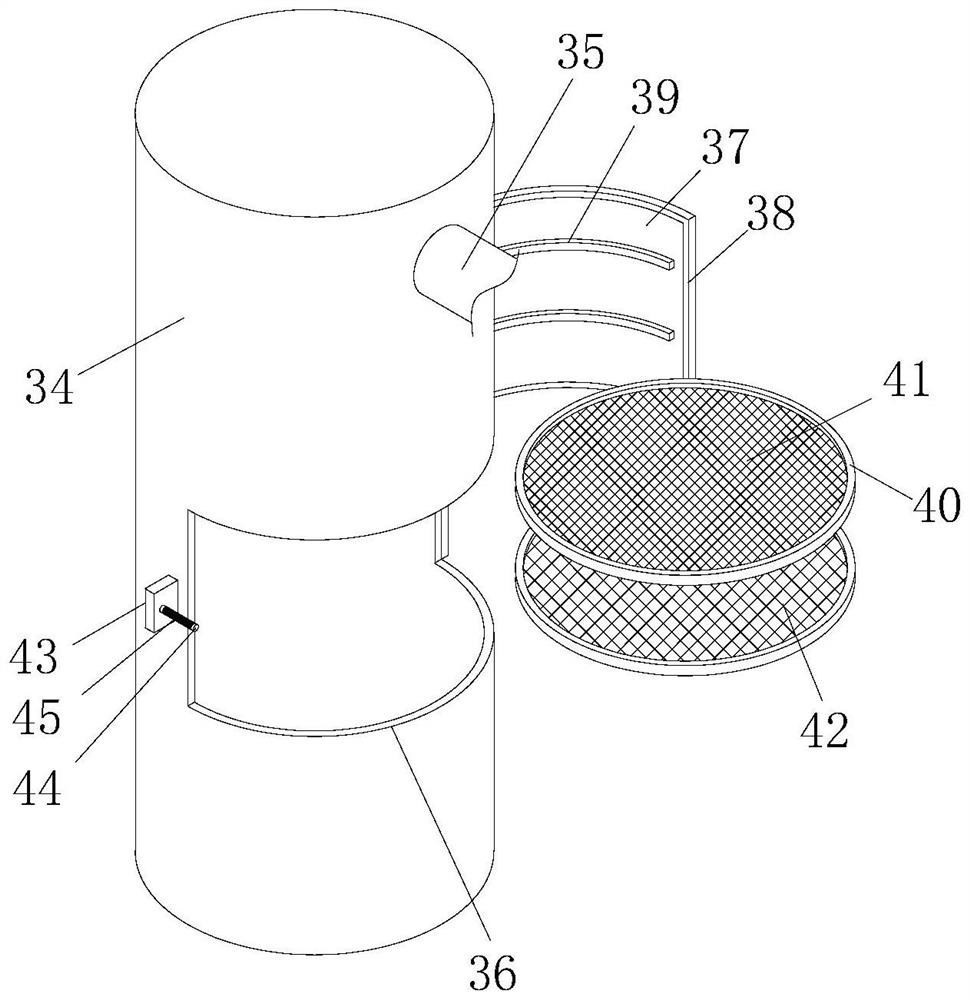

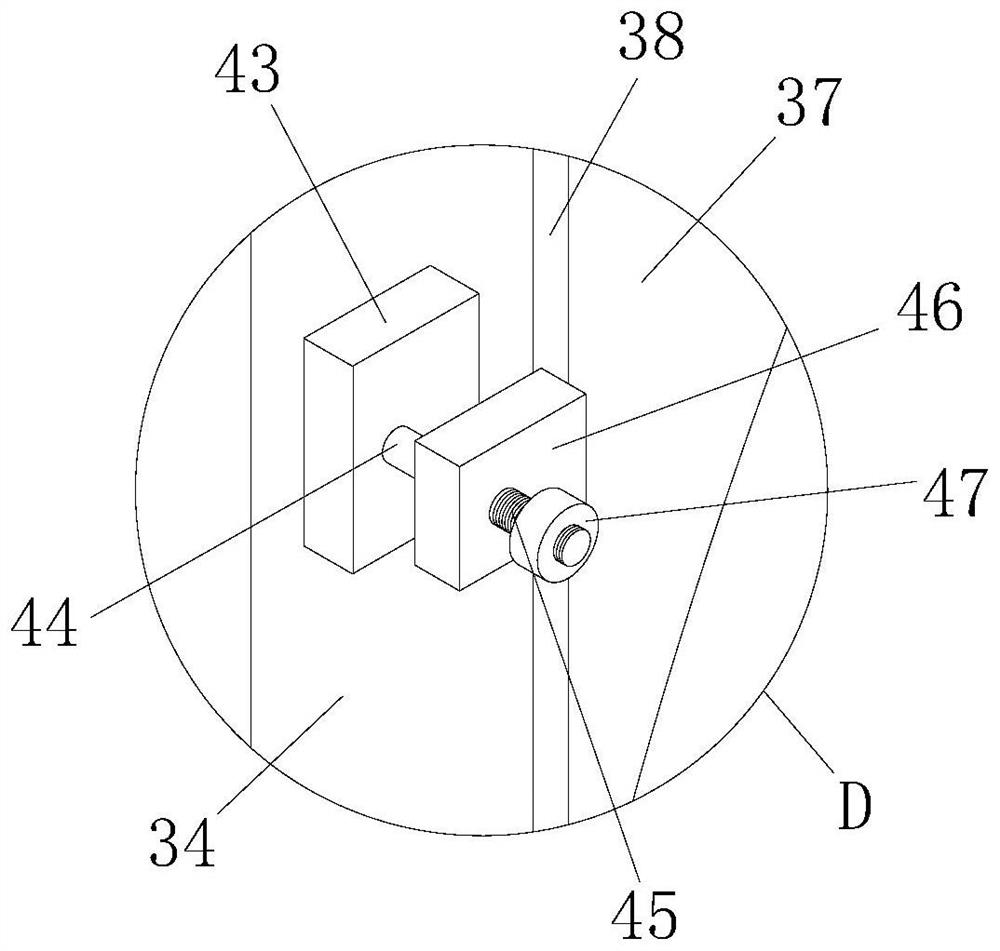

[0039] Embodiment: integrated atmospheric pressure shale gas drainage gas recovery and on-site treatment device, such as Figure 1-Figure 11As shown, it includes several equidistantly arranged bottom support mechanisms 1 and a load-bearing mechanism 2 fixedly installed on the top of the bottom support mechanism 1. The load-carrying mechanism 2 is a rectangular structure. The collection tank 3 is a circular internal hollow structure, and one of the outer surfaces of the collection tank 3 is fixedly installed with a delivery pipe 4 communicating with the inside of the collection tank 3 for transporting gas, and the delivery pipe 4 is far away from the end of the collection tank 3 A connection pipe 6 that can communicate with the inside of the delivery pipe 4 is fixedly connected to the connection sleeve 5. The connection pipe 5 has a Z-shaped internal hollow structure, and the inside of the connection pipe 6 is provided with a control that can control the delivery volume inside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com