Ordinary-pressure shale gas screen pipe completion hydraulic injection volume fracturing method

A hydraulic jetting and screen tube completion technology, applied in the field of drilling, can solve the problem of increasing the volume of normal pressure shale gas fracturing fractures, etc., and achieve the effect of increasing communication and extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

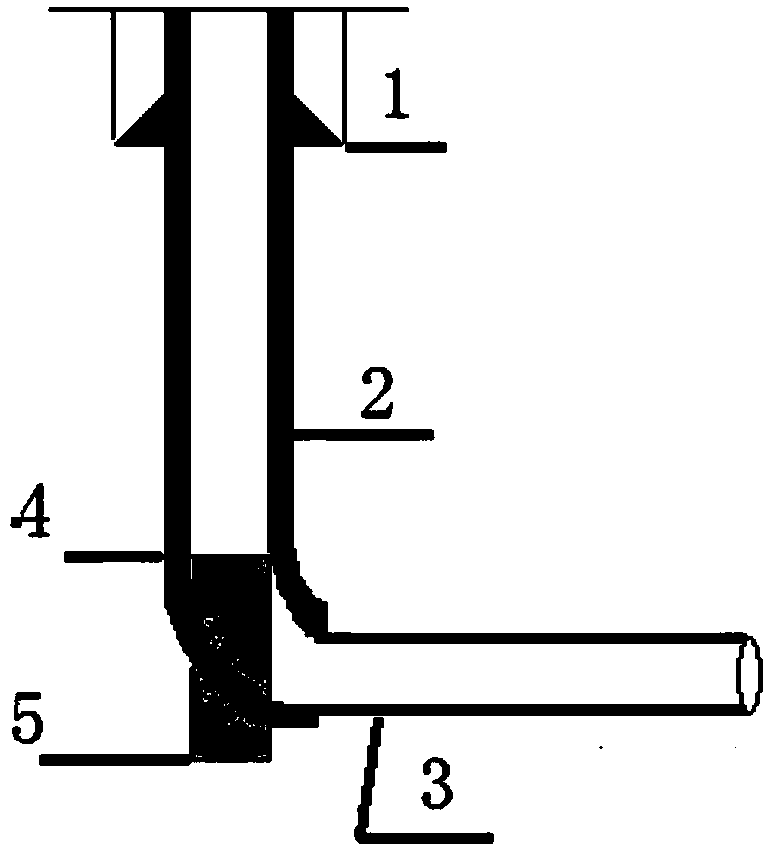

[0084] Such as figure 1 As shown in Fig. 1, the horizontal section of the normal pressure shale gas horizontal well is completed by the screen method.

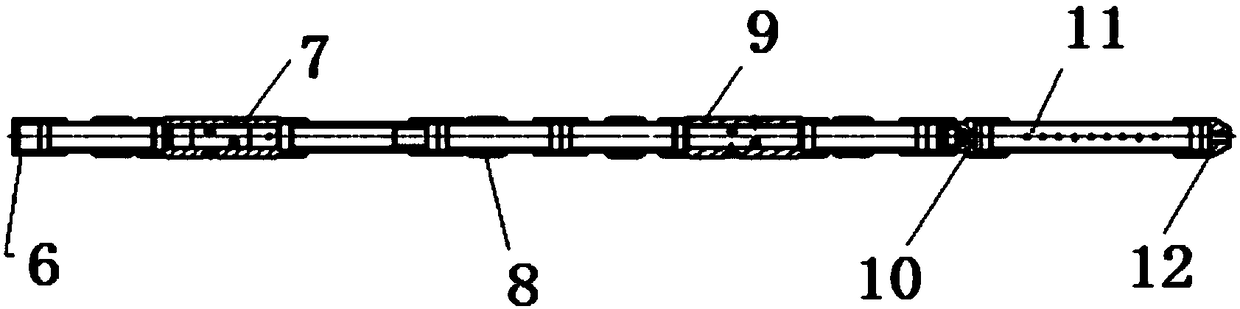

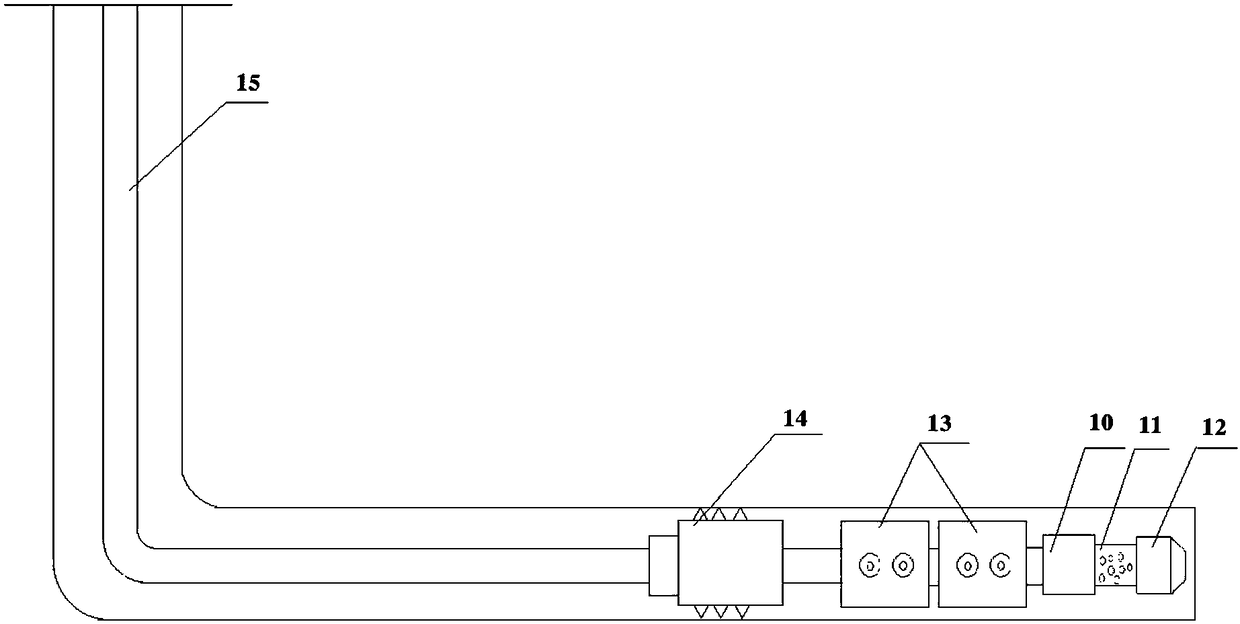

[0085] Such as figure 2 As shown, the new hydraulic jet volume fracturing string structure is mainly composed of coiled tubing (or ordinary tubing) + hydraulic anchor + 2-stage hydraulic injector + check valve + screen tube + guide head and so on.

[0086] Such as image 3 As shown, the two-stage hydro-ejector structure is directly connected by two-stage hydro-ejectors, and a centralizer is installed at each end of each ejector. Each stage of the hydraulic ejector of the present invention is configured with 4-8 nozzles according to geological requirements. Nozzle diameter 6mm-8mm. The number of injector nozzles is determined according to the optimal design of fracturing for each cluster. The screen pipe and check valve meet the needs of backwashing wells, and the guide head facilitates the smooth running of the pipe string...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com