Design method of two phase flow pump impeller

A design method and technology for pump impellers, which are applied to the components of pumping devices for elastic fluids, pumps and pumps for special fluids, etc. Uniform variation, small hydraulic and frictional losses, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the purpose, technical solutions and advantages of the present invention clearer, the implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings:

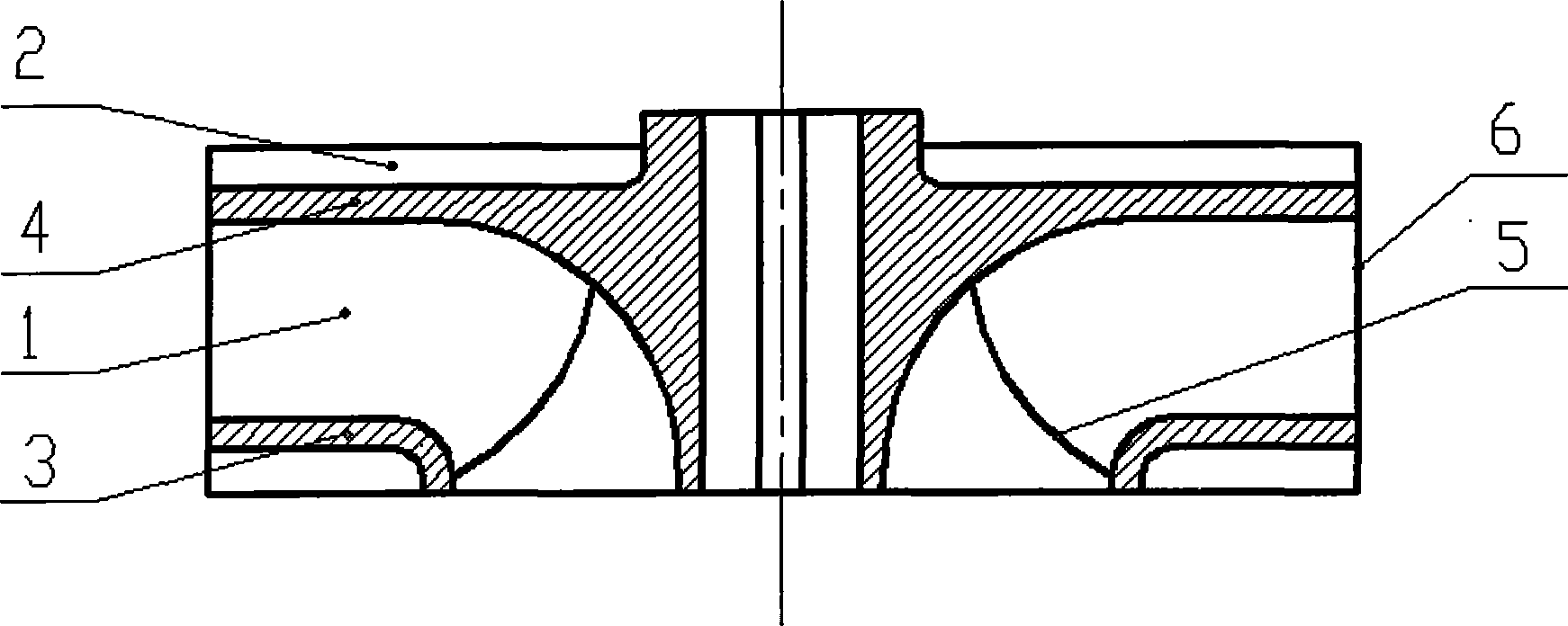

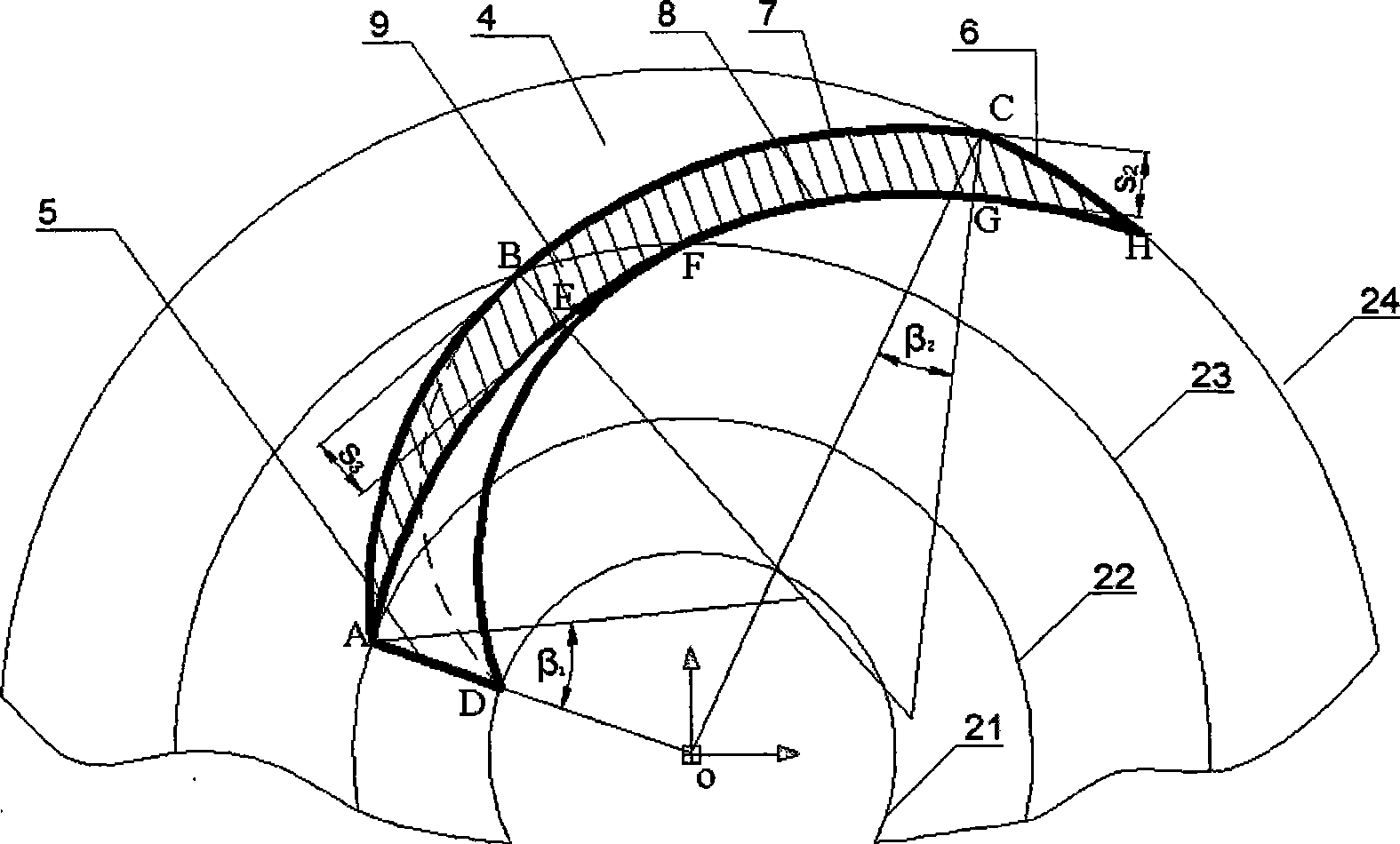

[0017] like figure 1 As shown, the impeller shaft surface structure of the present invention is shown, which mainly includes: impeller main blade 1, impeller auxiliary blade 2, impeller front cover plate 3, impeller rear cover plate 4, impeller inlet side 5 and impeller outlet side 6, The impeller main blade 1 is inclined from the blade inlet edge 5 to the impeller front cover plate 3 and the impeller rear cover plate 4, and the inclined shape transitions to be perpendicular to the front and rear cover plates, forming a semi-twist that the outlet section is perpendicular to the two side cover plates blade. The profile of the main blade 1 of the impeller adopts an arc shape, usually 2-3 segments of arcs. It also includes: firstly determine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com