Biological dredging platform and method

An ecological and platform technology, applied in the field of water conservancy dredging and ecological dredging, can solve the problems that hydraulic winches cannot be used to pull ropes on the hull, labor-intensive, inconvenient, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

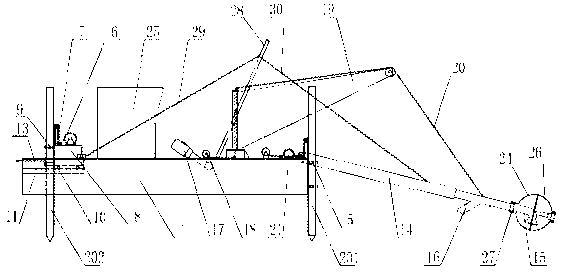

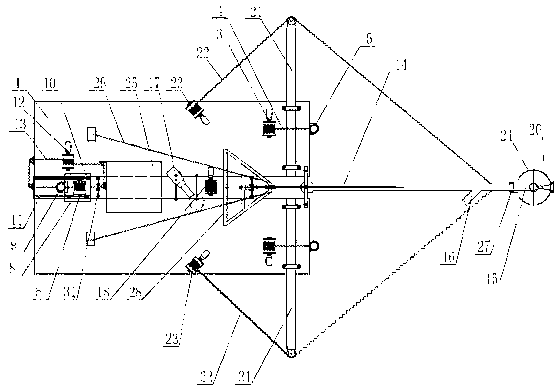

[0026] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0027] See figure 1 , figure 2 The ecological dredging platform of the present invention includes a hull 1, positioning piles, a cockpit 25 and a dredging device. The hull 1 is a double hull, and the double hulls are fixedly connected by a connecting plate 31; The front pile 201 of the side and the rear pile 202 of the hull 1 afterbody, the front pile 201 is controlled lifting by electric winch-3 and steel rope-4, and the quantity of front pile 201 is at least two, and electric winch-3, steel rope-4 The quantity corresponds to the quantity of the front pile 201. One end of the steel rope one 4 is fixed on the front pile 201, and the other end is connected with the electric winch one 3 after going around the fixed pulley on the hull 1, and the buckle one 5 is fixedly connected to the front side of the hull 1 , for clamping the front pile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com