Deep sludge dewatering process

A deep dewatering and sludge technology, which is applied in dewatering/drying/concentrating sludge treatment, combustion methods, lighting and heating equipment, etc., can solve the problems of unfavorable sludge treatment resource utilization, 70-80%, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

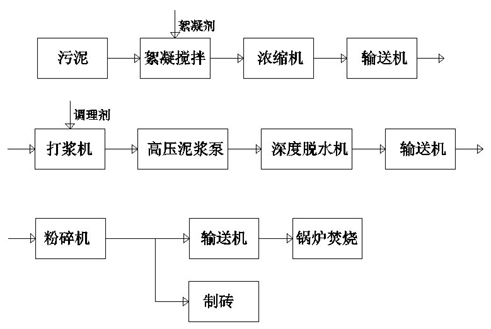

Image

Examples

Embodiment 1

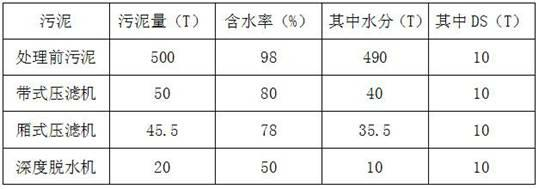

[0020] The sludge deep dewatering process includes the following steps:

[0021] 1) The sludge with a moisture content of more than 96% produced after sewage treatment is pumped to the flocculation stirring reaction tank, and polymer flocculant is added for flocculation reaction; the polymer flocculant added in the flocculation stirring reaction tank is polymer The weight ratio of acrylamide, polyacrylamide and sludge with a moisture content of more than 96% is 1 to 5:10000;

[0022] 2) After the flocculation reaction, the sludge overflows to the thickener for concentration and dehydration, so that the moisture content of the sludge is 85-90%;

[0023] 3) The sludge with a moisture content of 85-90% is transported from the conveyor to the beater, and chemical conditioners are added for beating and conditioning; the chemical conditioners are calcium carbonate or calcium oxide, calcium carbonate or calcium oxide and a moisture content of 85- The weight ratio of 90% of the sludg...

Embodiment 2

[0028] The sludge deep dewatering process includes the following steps:

[0029] 1) The sludge with a moisture content of more than 96% produced after sewage treatment is pumped to the flocculation stirring reaction tank, and polymer flocculant is added for flocculation reaction; the polymer flocculant added in the flocculation stirring reaction tank is polymer The weight ratio of acrylamide, polyacrylamide and sludge with a moisture content of more than 96% is 2:10000;

[0030] 2) After the flocculation reaction, the sludge overflows to the thickener for concentration and dehydration, so that the moisture content of the sludge is 85-90%;

[0031] 3) The sludge with a moisture content of 85-90% is transported from the conveyor to the beater, and chemical conditioners are added for beating and conditioning; the chemical conditioners are calcium carbonate or calcium oxide, calcium carbonate or calcium oxide and a moisture content of 85- The weight ratio of 90% of the sludge is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com