Recycling method for deeply dewatering municipal sludge and gasifying and pyrolyzing sludge cake by aid of water vapor to produce hydrogen

A deep dewatering, municipal sludge technology, applied in gasification process, fixed bed gasification, pyrolysis treatment of sludge, etc., can solve problems such as difficult to fully contact, discounted catalytic pyrolysis effect, and uniform distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

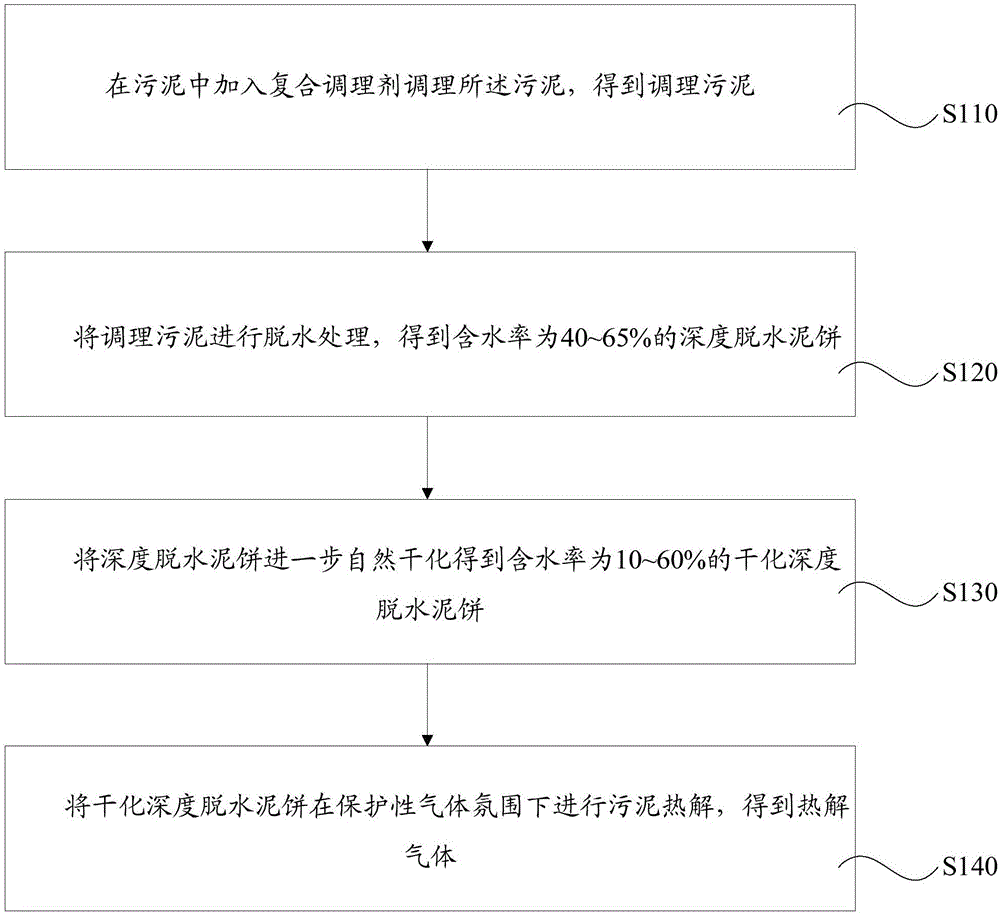

[0058] The recycling method of deep dehydration of municipal sludge and steam gasification and pyrolysis of mud cake to produce hydrogen in this embodiment is carried out according to the following steps:

[0059] (1) Add 30kg of sludge into the sludge conditioning tank, add sulfuric acid solution to adjust the initial pH of the sludge to 5, and then add 8mol / LFeSO 4 Stir 2.41L of the solution, the stirring speed is 120rpm, and the stirring time is 2min, then add 3L of 10mol / L hydrogen peroxide for stirring, the stirring speed is 70rpm, and the stirring time is 25min, so that the oxidation reagent and the sludge fully react, and finally add 8kg red mud, and fast stirring for conditioning, the stirring speed is 120rpm, the stirring time is 6min, wherein, the oxide mass percentage content of iron in the red mud is 8%, the oxide mass percentage content of aluminum is 12%, the titanium content The mass percent content of oxides is 3%, the mass percent content of silicon dioxide an...

Embodiment 2

[0065] The recycling method of deep dehydration of municipal sludge and steam gasification and pyrolysis of mud cake to produce hydrogen in this embodiment is carried out according to the following steps:

[0066] (1) Put 30kg of sludge into the sludge conditioning tank, add hydrochloric acid solution to adjust the initial pH of the sludge to 7, and then 20mol / LFeCl 2 Stir 0.96L of the solution at a stirring speed of 150rpm for 3 minutes, then add 3.33L of 8mol / L hydrogen peroxide for stirring at a stirring speed of 100rpm and a stirring time of 30min to fully react the oxidizing agent and the sludge, and finally add Add 6.87kg red mud, and stir quickly for conditioning, the stirring speed is 150rpm, and the stirring time is 10min, wherein the mass percentage of iron oxide in the red mud is 40%, and the mass percentage of aluminum oxide is 13%. The mass percent content of titanium oxide is 11%, the mass percent content of silicon dioxide and other minerals is 36%, and finally ...

Embodiment 3

[0072] The recycling method of deep dehydration of municipal sludge and steam gasification and pyrolysis of mud cake to produce hydrogen in this embodiment is carried out according to the following steps:

[0073] (1) Put 30kg of sludge into the sludge conditioning tank, add sulfuric acid solution to adjust the initial pH of the sludge to 6, and then add 15mol / L FeSO 4 Stir 0.88L of the solution, the stirring speed is 200rpm, and the stirring time is 4min, then add 3L of 12mol / L hydrogen peroxide for stirring, the stirring speed is 120rpm, and the stirring time is 40min, so that the oxidation reagent and the sludge fully react, and finally add 7.5kg red mud, and fast stirring for conditioning, the stirring speed is 100rpm, the stirring time is 15min, wherein, the oxide mass percentage content of iron in the red mud is 42%, the oxide mass percentage content of aluminum is 15%, titanium The mass percent content of oxides was 12%, the mass percent content of silicon dioxide and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com