Electroosmosis sludge dewatering equipment

A sludge dewatering machine and sludge dewatering technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of high cost, complex equipment structure, failure to fully utilize electroosmosis, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

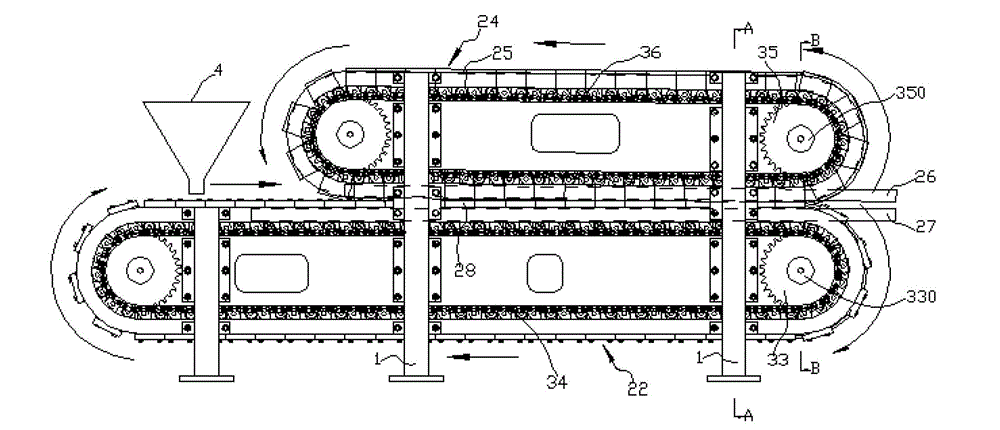

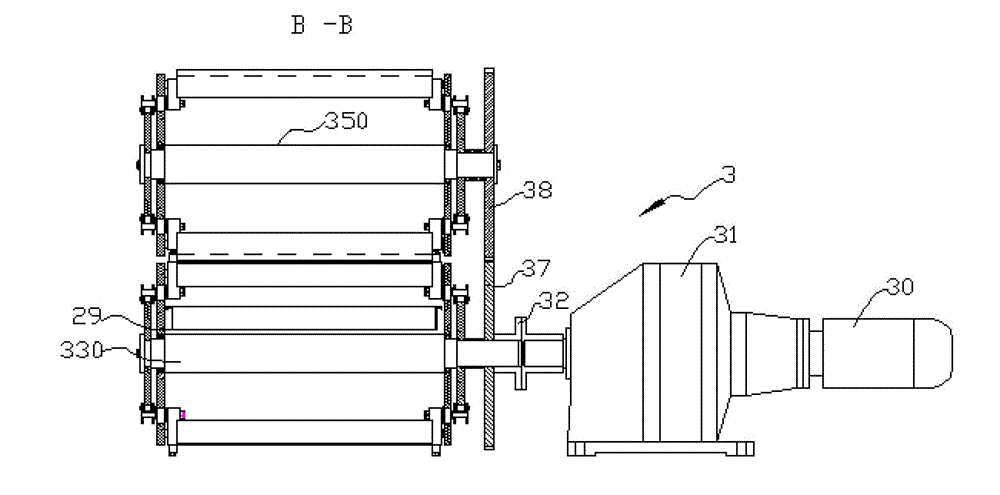

[0029] Such as Figure 1 to Figure 10 As shown, the electroosmotic sludge dewatering machine provided in this embodiment mainly includes a frame 1, a sludge dewatering device 2, a driving mechanism 3, a power supply (not shown in the figure), a feeding hopper 4, and a scraper 5. The specific structures of the sludge dewatering device 2 and the drive mechanism 3 will be described in detail below.

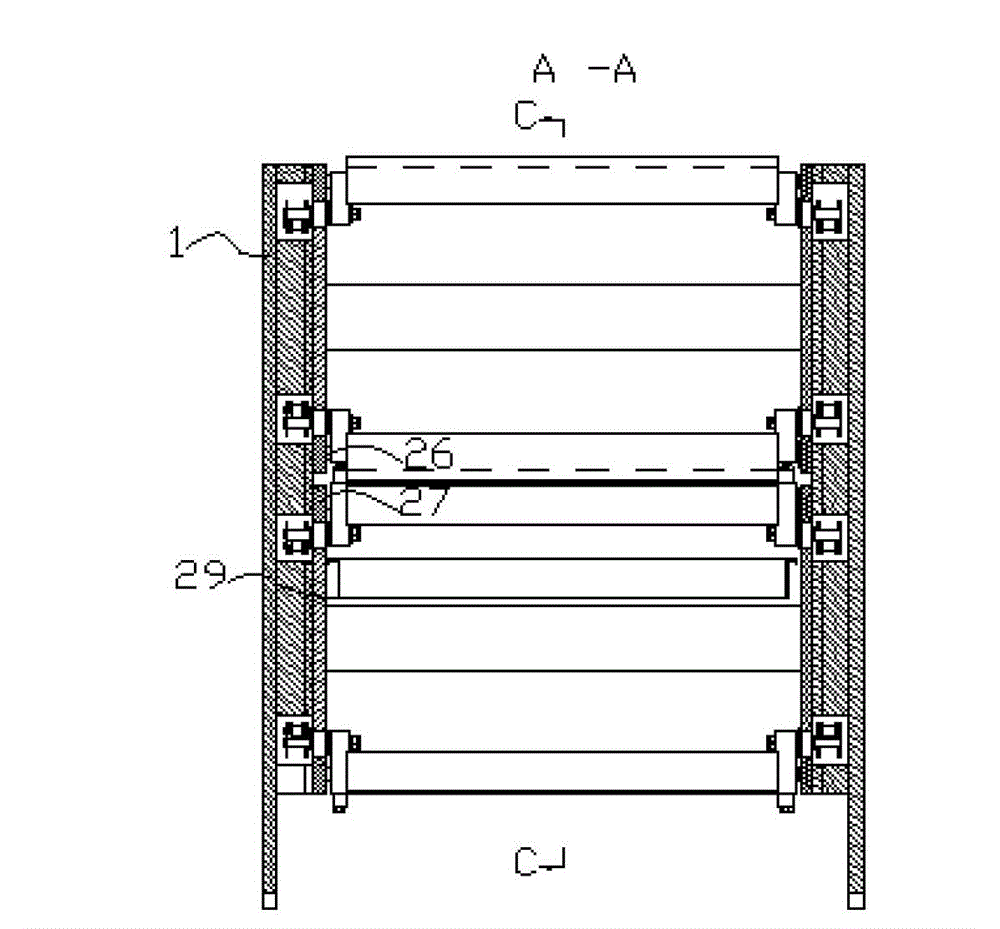

[0030] In this example, the sludge dewatering device 2 includes an annular upper guide rail 20 fixed on the frame 1, an annular lower guide rail 21 fixed on the frame 1 and located below the annular upper guide rail 20, a plurality of screen trolleys 22, a plurality of The moving net plate 23 , a plurality of extruding trolleys 24 , a plurality of extruding plates 25 , conductive plates 26 , 27 and a sewage pan 29 located below the moving net plate 23 . The centerlines of the annular upper guide rail 20 and the annular lower guide rail 21 extend along the horizontal direction, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com