Device and method for magnetic separation of underwater sludge

A treatment method and a treatment device technology, applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems that the effluent cannot be discharged directly, low energy consumption and land occupation, etc., and achieve dredging cost reduction, increase efficiency, and sludge output big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

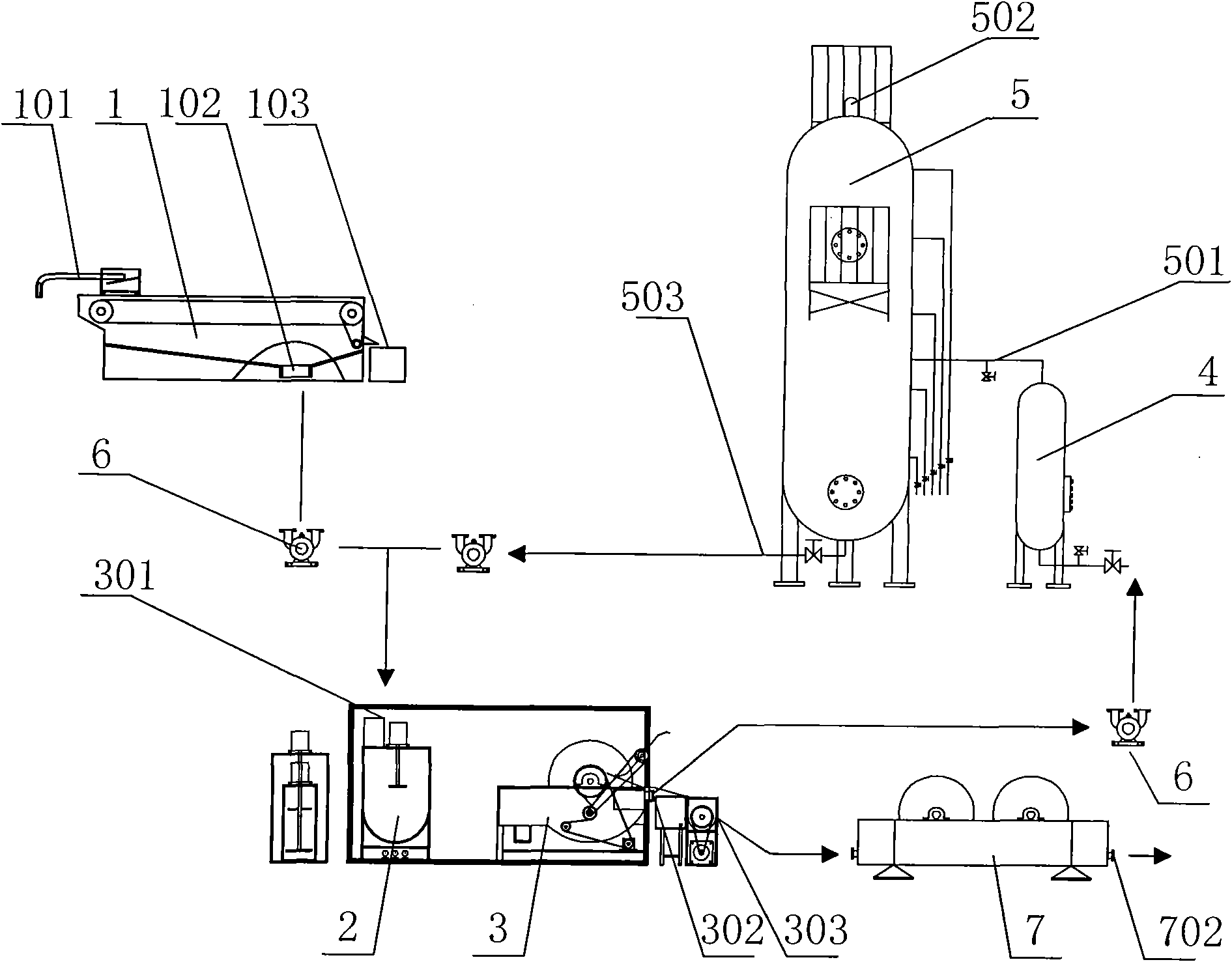

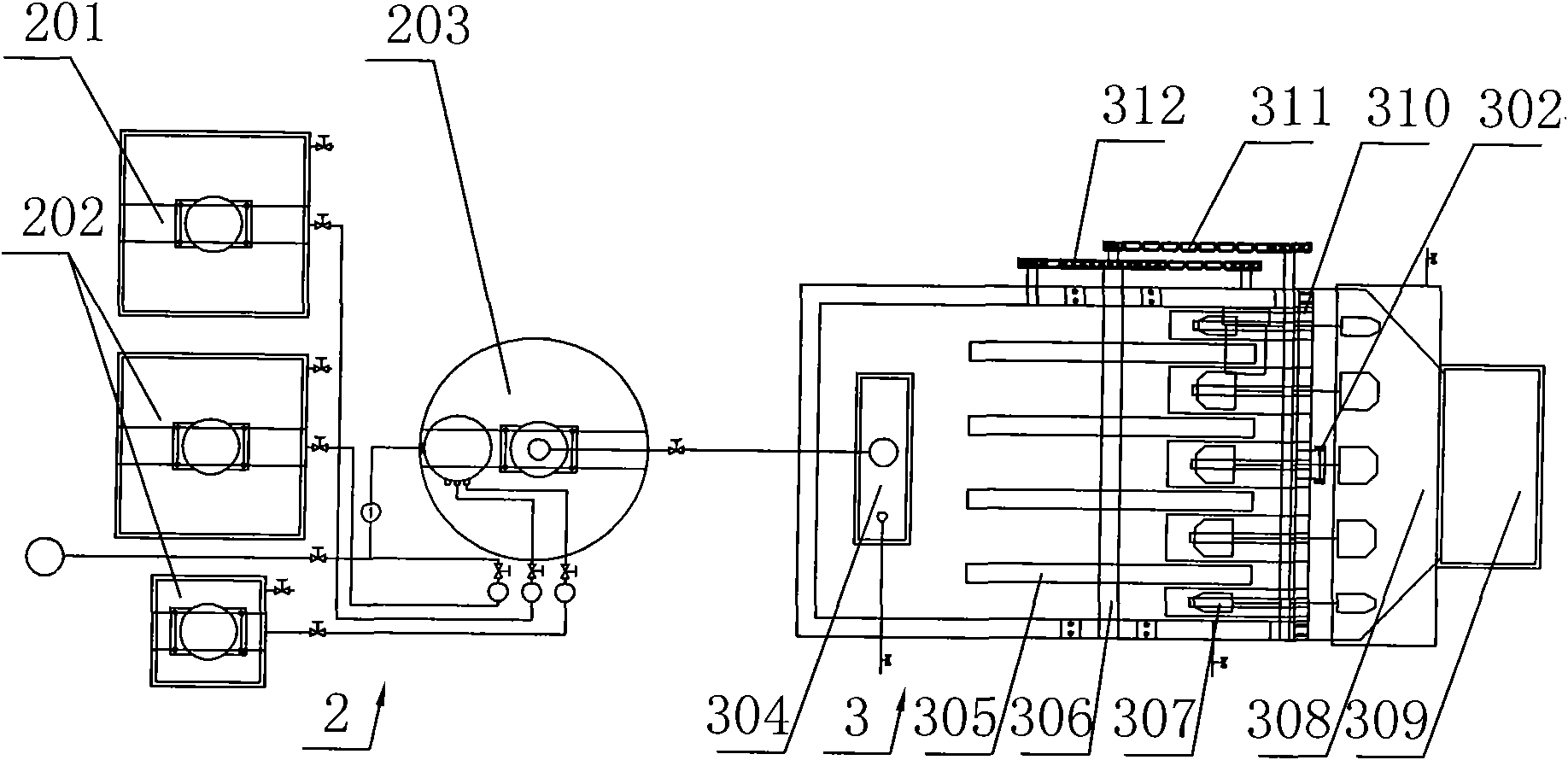

[0026] Such as figure 1 As shown, the treatment device of the underwater sludge of the present invention includes a rolling screen 1 connected in series by a screw pump 6, a flocculation tank 2, a magnetic separation device 3, a reaction tank 4 and a sludge separation tower 5, wherein the upper stage treatment The water outlet of the device is connected to the inlet of the next-stage treatment device, and the mud outlet 503 of the separation tower 5 is connected to the inlet 301 of the magnetic separation equipment through the screw pump 6 .

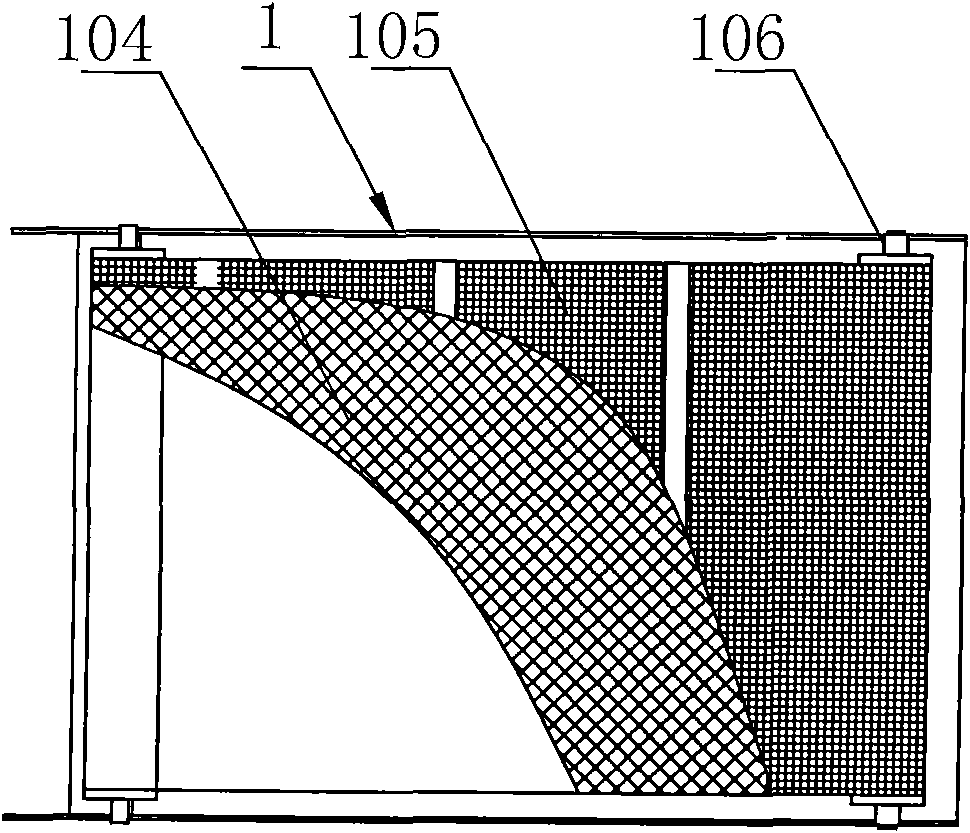

[0027] For the actual workflow see Figure 1 to Figure 6 : muddy sewage is sucked in from the inlet 101 by the mud pump, and falls on the rolling screen 105, such as figure 2 As shown, the bottom of the screen 105 is supported by a support net 104, which can reciprocate around the cylinders 106 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com