Oil and gas field high-sulfur-content waste water processing method

A waste water treatment, high sulfur content technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problem of incomplete chemical oxidation treatment, increased cost, Eliminate fuel consumption and other issues, and achieve the effect of eliminating hydrogen sulfide and sulfide pollution, reducing hazards and safety hazards, and reducing environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

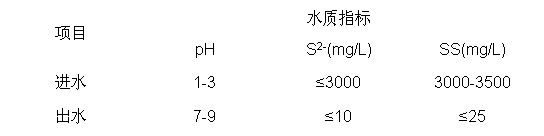

[0017] Example 1: Add the waste water into the closed reaction tank, and treat the waste water per cubic meter according to the following formula: lime: 5kg, ferrous sulfate: 1kg, and pump the hydrogen sulfide gas escaped from the closed reaction tank into the biological desulfurization reaction device. Treatment: adding polyaluminum chloride: 4.5kg, the treated water is filtered through a plate and frame filter press for mud-water separation, the separated filtrate enters subsequent wastewater treatment, and the separated sludge cake is solidified on site.

[0018] The water quality indicators for treatment after mud-water separation are attached figure 1 shown.

[0019] The subsequent wastewater treatment method for the water after mud-water separation is as follows: the separated filtrate enters the oxidation tank for oxidation reaction. After 12 hours of reaction, the water quality after the reaction is tested, and if the treatment reaches the standard, it is discharged,...

example 2

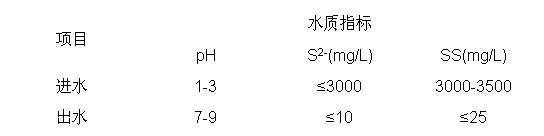

[0020] Example 2: Add the waste water into the closed reaction tank, and treat the dosage of waste water per cubic meter according to the following formula: sodium hydroxide: 4kg, ferrous sulfate: 3kg, pump the hydrogen sulfide gas escaped from the closed reaction tank to the biological desulfurization reaction Treatment is carried out in the device; polyaluminum chloride: 4kg is added, and the treated water is filtered through a plate-and-frame filter press for mud-water separation, and the separated filtrate enters subsequent wastewater treatment, and the separated sludge cake is solidified on site.

[0021] The water quality indicators for treatment after mud-water separation are attached figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com