Sludge dewatering membrane filter press and filtration method thereof

A diaphragm filter press and filtration method technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of inability to transport, affect the daily sludge treatment volume and working environment, and cannot be recycled, and achieve fast filtration speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

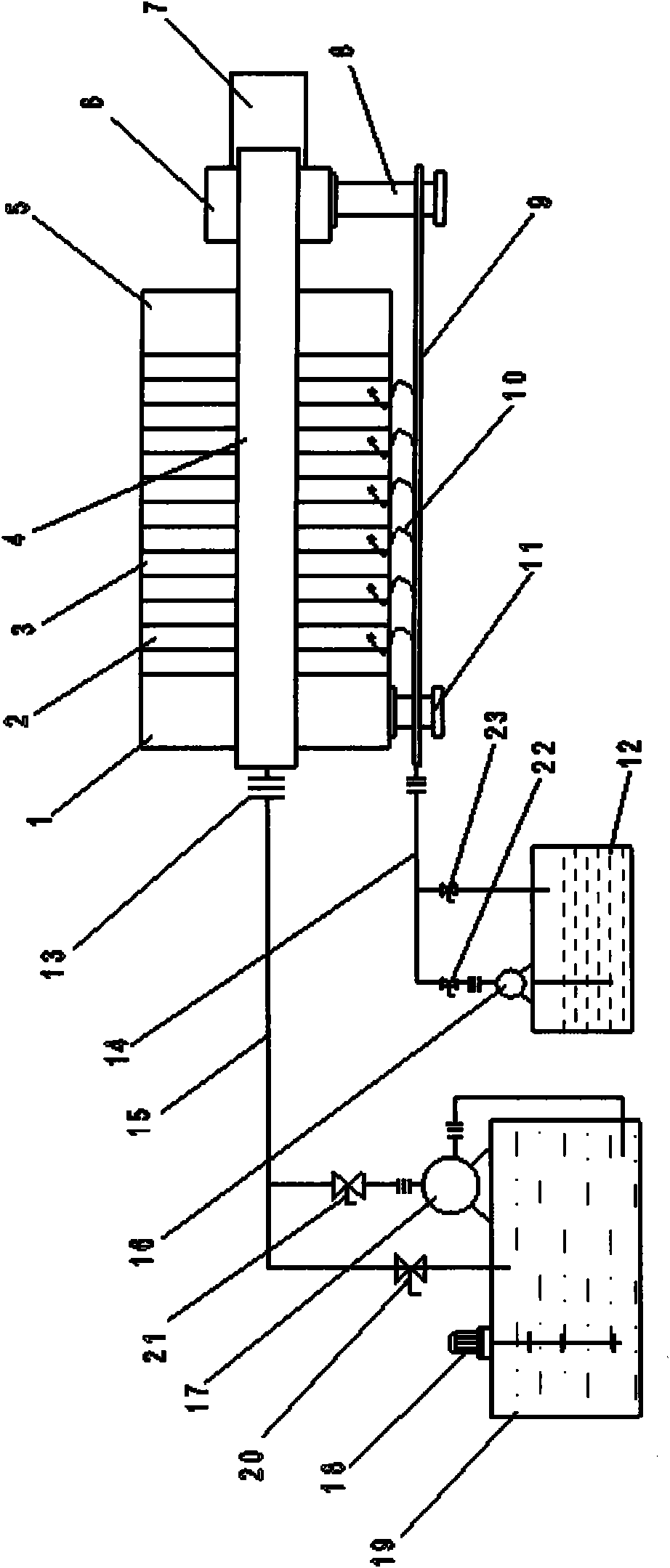

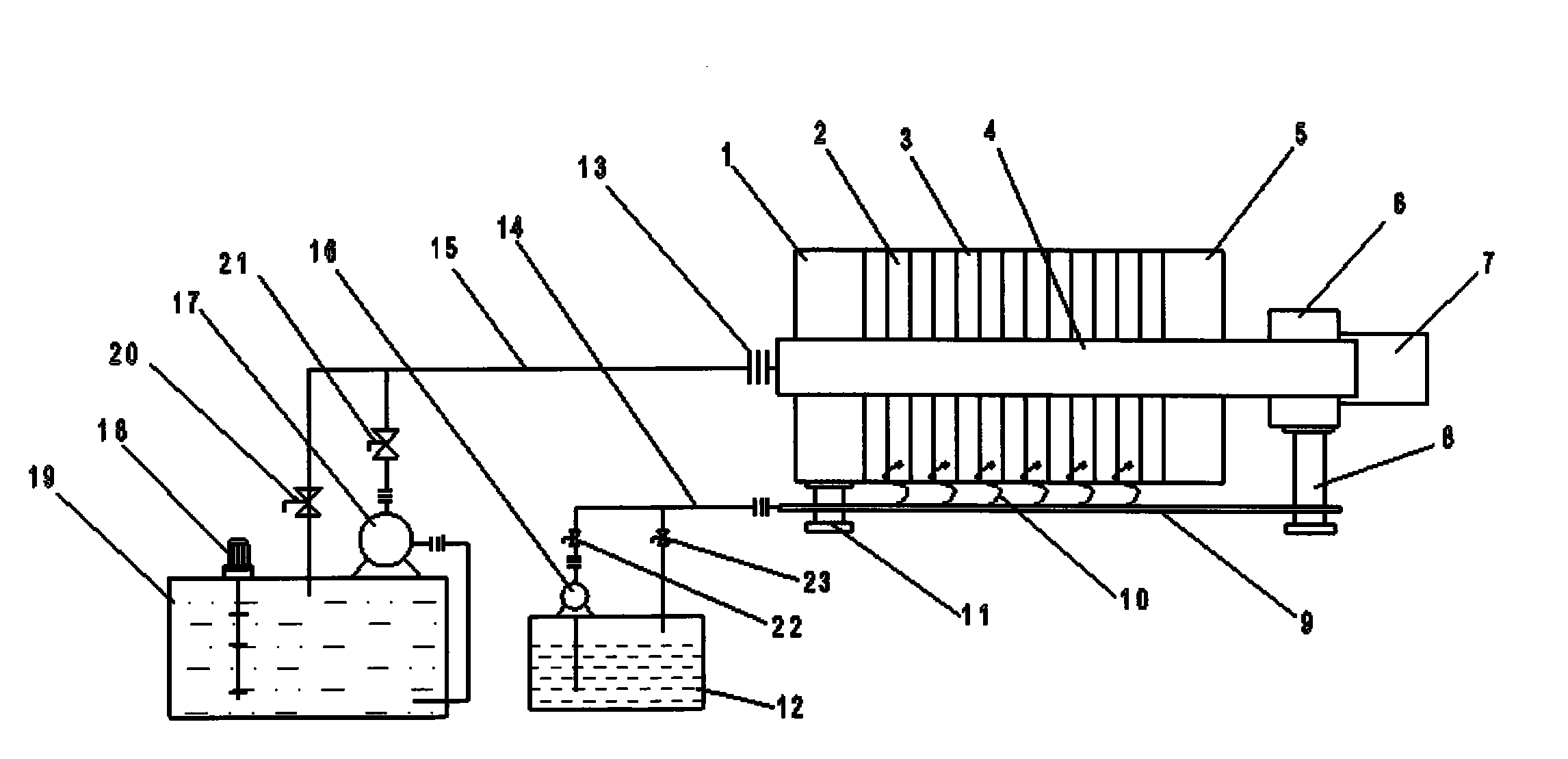

[0012] Please combine figure 1 As shown, the present invention provides a sludge dewatering diaphragm filter press and a filtering method thereof. The frame part of the diaphragm filter press is composed of a main beam 4 connected to a thrust plate 1 and a frame 6 fastened with bolts. The material used for the main beam 4 It is welded with Q345B manganese steel, the compression plate 5 is installed on the upper end of the main beam 4, the material used for the thrust plate 1, the compression plate 5 and the frame 6 is welded by Q235B carbon structural steel, and the front outrigger frame 8 is bolted Fastened to the lower end of the machine base 6, the rear outrigger frame 11 is installed on the lower end of the thrust plate 1 with bolts, and the hydraulic part is assembled by the hydraulic cylinder 7. The structure is a known technology and will not be described here. The hydraulic cylinder 7 is installed on the machine. The center hole of the seat 6 is connected by bolts, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com