Magnetic coagulation mine water underground purification technology

A purification process and magnetic coagulation technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. Environmental impact and other issues, to achieve the effect of saving the amount of chemicals used, short purification and separation time, high field strength and gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

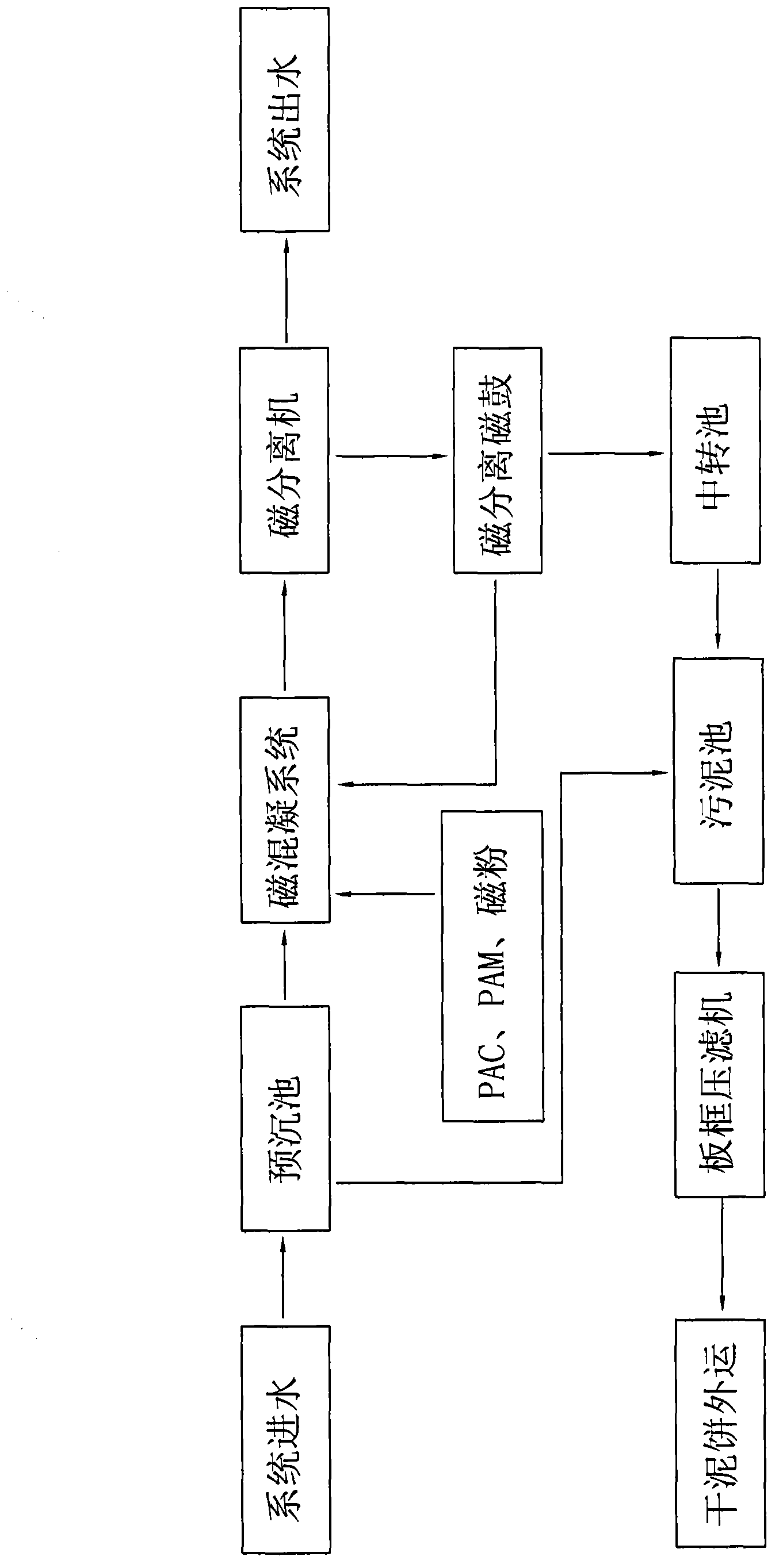

[0022] Such as figure 1 Shown, the underground purification process of magnetic coagulation mine water of the present invention is carried out according to the following steps:

[0023] A. The mine water is collected to the front end of the underground central water tank through the ditches in the roadway, and then flows into the pre-sedimentation tank for sedimentation after being cleaned and filtered. A submersible slurry pump is installed in the pre-settling tank, and the submersible slurry pump regularly removes the sludge in the pre-settling tank into the sludge tank.

[0024] B. The water treated by the pre-sedimentation tank flows into the magnetic coagulation system. The magnetic coagulation system adds magnetic powder and coagulant to the water. The coagulant is PAC and PAM. The suspended solids in the water form within 3 minutes with magnetic powder as the carrier. microflocs.

[0025] C. After coagulation, the water flows into the magnetic separator. The magnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com