Municipal sludge two-stage deep dehydration method combining chemical regulation strengthening preliminary mechanical dehydration and electroosmosis

A technology of deep dewatering and municipal sludge, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve problems such as unsatisfactory effect and sludge modification, achieve good dehydration effect, high treatment efficiency, and realize continuous operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

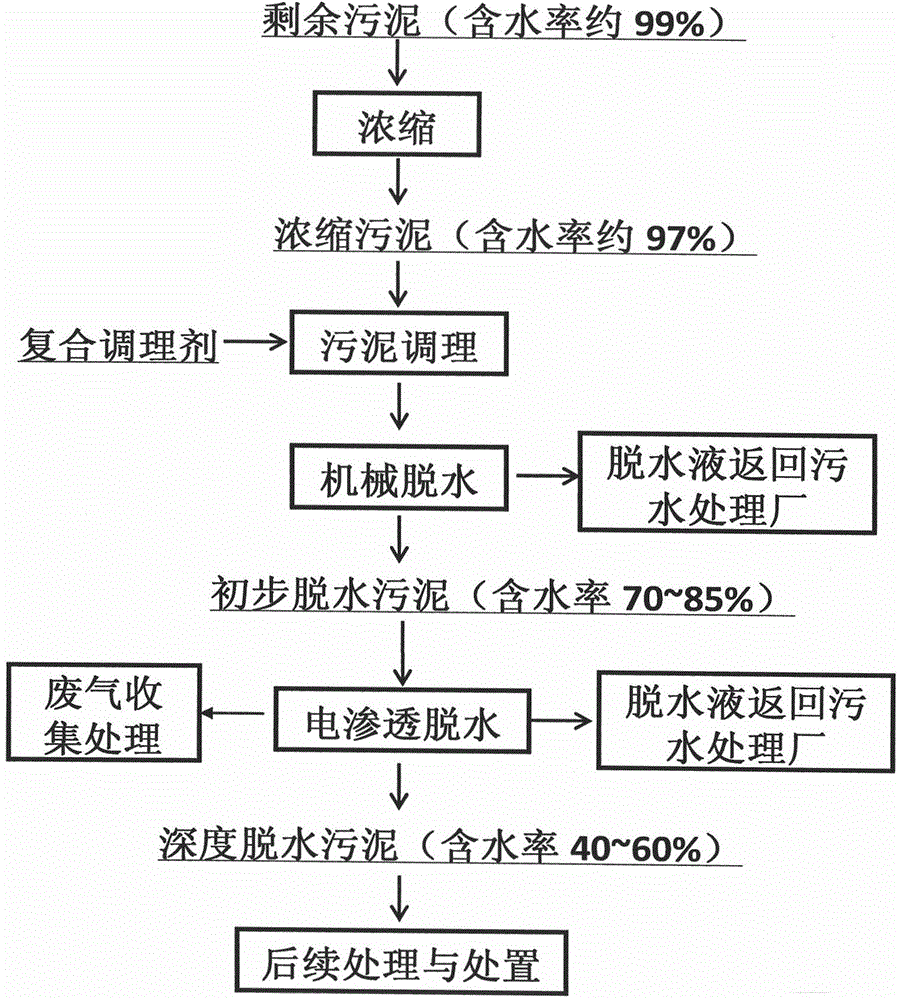

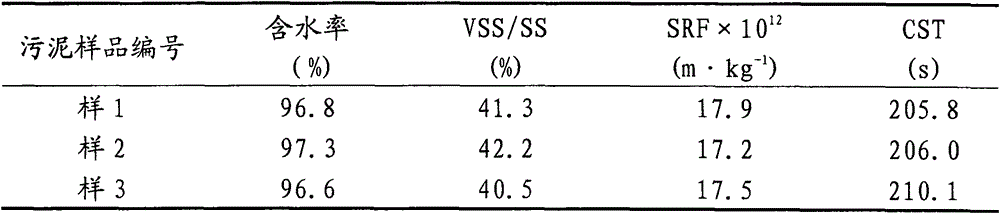

[0046] First, the remaining activated sludge with a water content of 99.2% in the sewage treatment plant is transported to the sludge thickening tank through a screw pump, and concentrated by gravity to obtain concentrated sludge with a water content of 96.8%. The concentrated sludge is transported to the sludge conditioning tank through a screw pump, and a compound conditioner about 4.5% of the dry basis weight of the sludge is added. Control the working frequency of the stirring motor in the conditioning tank to 30 Hz, and stir for 20 minutes to obtain the modified conditioned sludge. The conditioned sludge is transported to the belt filter press for preliminary dehydration through a screw pump to obtain a soft preliminary dewatered sludge with a moisture content of 75.4%. The dewatered filtrate during the preliminary dehydration process is returned to the sewage treatment unit of the sewage treatment plant.

[0047] Then, the preliminary dewatered sludge with a moisture con...

Embodiment 2

[0049] First, the remaining activated sludge with a water content of 99.4% in the sewage treatment plant is transported to the sludge thickening tank through a screw pump, and concentrated by gravity to obtain concentrated sludge with a water content of 97.3%. The concentrated sludge is transported to the sludge conditioning tank through a screw pump, and a compound conditioner about 25.4% of the dry weight of the sludge is added. Control the working frequency of the stirring motor in the conditioning tank to 30 Hz, and stir for 20 minutes to obtain the modified conditioned sludge. The conditioned sludge is transported to the centrifuge through the screw pump for preliminary dehydration to obtain soft preliminary dewatered sludge with a moisture content of 72.6%. The dewatered filtrate during the preliminary dehydration process is returned to the sewage treatment unit of the sewage treatment plant.

[0050] Then the preliminary dewatered sludge with a moisture content of 75.6%...

Embodiment 3

[0052] First, the remaining activated sludge with a water content of 99.3% in the sewage treatment plant is transported to the sludge thickening tank through a screw pump, and concentrated by gravity to obtain concentrated sludge with a water content of 96.6%. The concentrated sludge is transported to the sludge conditioning tank through a screw pump, and a compound conditioner about 9.4% of the dry basis weight of the sludge is added. Control the working frequency of the stirring motor in the conditioning tank to 30 Hz, and stir for 20 minutes to obtain the modified conditioned sludge. The conditioned sludge is transported to the centrifuge by the screw pump for preliminary dehydration to obtain soft preliminary dewatered sludge with a moisture content of 75.5%. The dewatered filtrate during the preliminary dehydration process is returned to the sewage treatment unit of the sewage treatment plant.

[0053] Then the preliminary dewatered sludge with a moisture content of 75.5%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Calorific value | aaaaa | aaaaa |

| Calorific value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com