Method for preparing core-shell ferroferric oxide/graphene oxide composite nano-catalyst

A technology of ferroferric oxide and nano-catalysts, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve secondary pollution of iron-containing sludge, hydrogen peroxide Utilize the problems of low efficiency and refractory organic matter to achieve excellent degradation effect, easy control of the reaction process, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

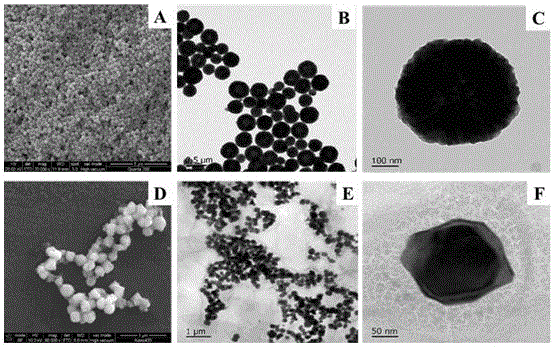

Image

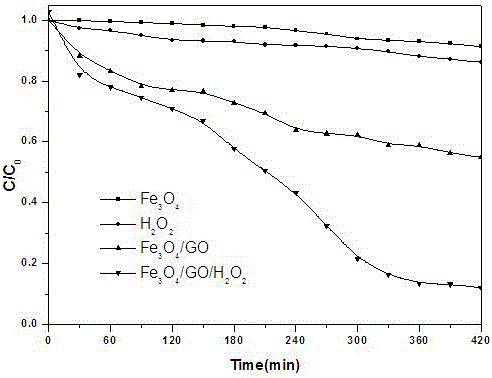

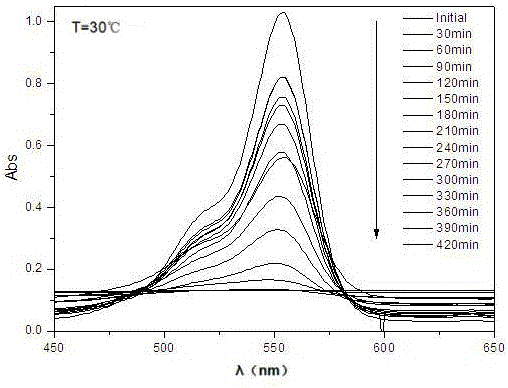

Examples

Embodiment 1

[0026] 2.025gFeCl 3 ·6H 2 O was dissolved in 60ml of ethylene glycol solution, and magnetically stirred for 30min; then 10.8g of sodium acetate and 3.0g of polyethylene glycol 4000 were added in sequence, and magnetically stirred for 45min; Dissolve 1.0g of nanometer iron ferric oxide in 100ml of ethylene glycol, when the ultrasonic power is 250W and the ultrasonic frequency is 40000KH z Ultrasonic dispersion for 30min, add 1.0mL of aminopropyltrimethoxysilane, reflux at 80°C for 24h; wash the resulting solution with water first, then wash with ethanol, and then vacuum-dry for 12 hours at a vacuum degree of 0.05Mpa and a temperature of 60°C. Obtain aminated nanometer ferric oxide;

[0027] Mix 2g of graphite, 120ml of concentrated sulfuric acid, and 30ml of concentrated nitric acid mechanically at 0°C for 1.5h, then add 15g of potassium permanganate to the mixture, and stir at room temperature for 96h; after the reaction is complete, add 500ml of distilled water, Stir at 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com