Method and device for disposing animal manure to produce organic fertilizer by solar energy

A technology of livestock and poultry manure and solar energy, which is applied in the preparation of organic fertilizers, organic fertilizers, fertilization devices, etc., can solve the problems of total nutrient loss and achieve the effects of saving energy, shortening the time of watering, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

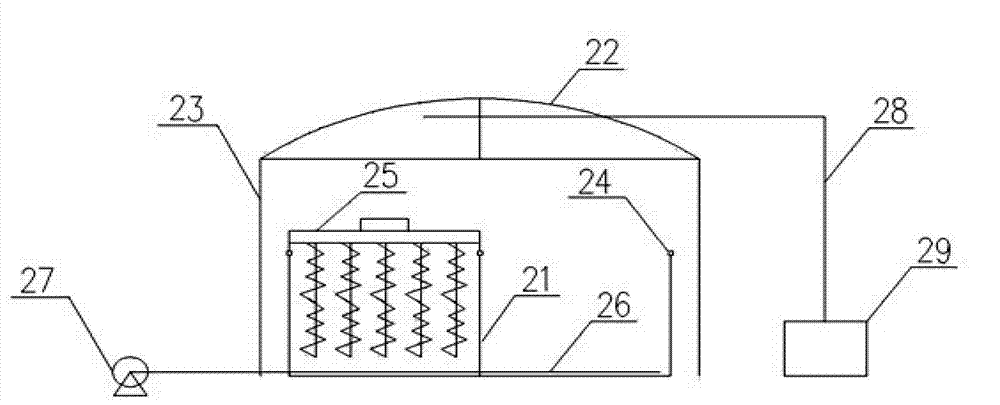

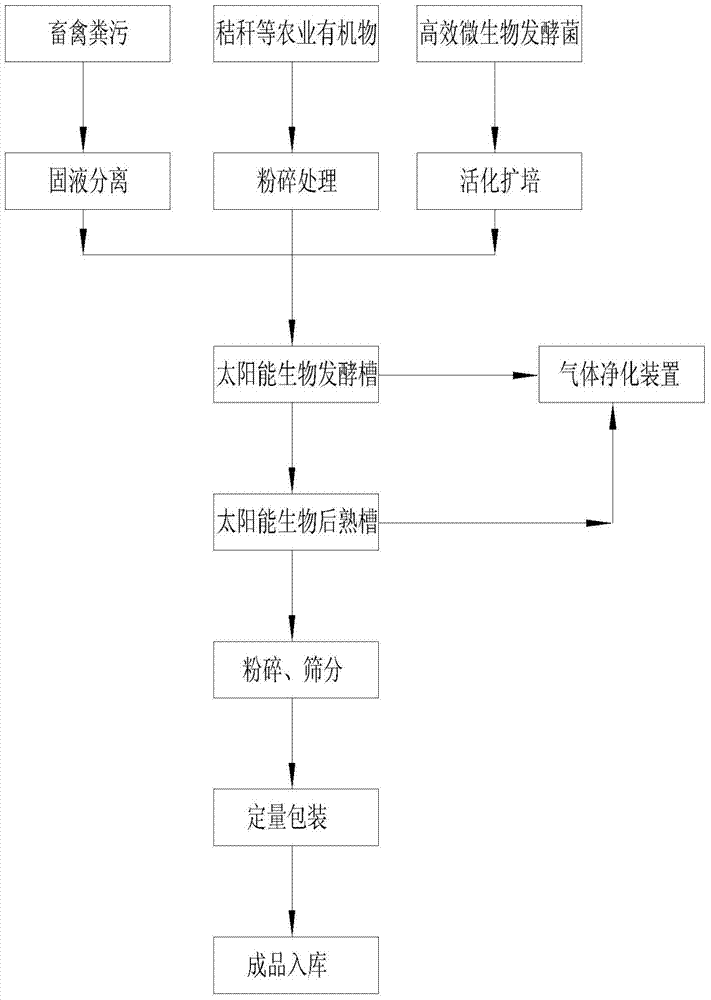

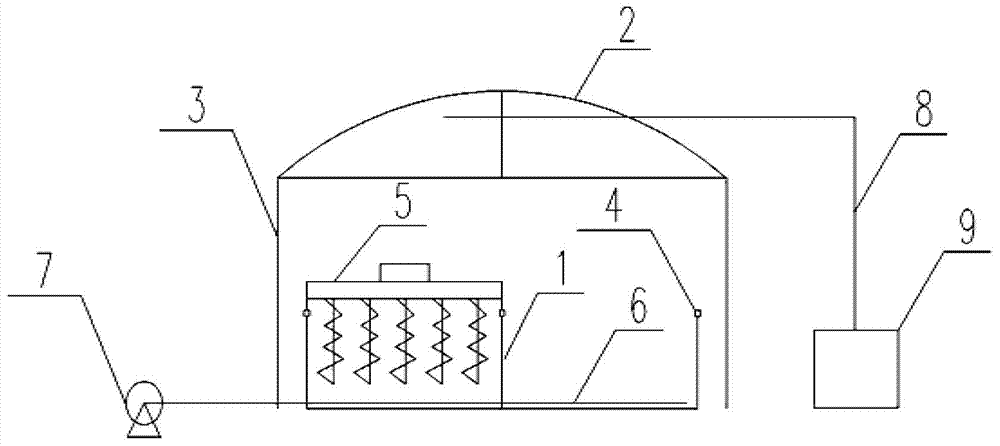

[0046] Livestock and poultry manure is dehydrated by solid-liquid separation, controlling moisture to 70%, adding 30% mass ratio of crushed straw, and then adding high-efficiency microbial fermentation bacteria agent nitrogen-fixing bacteria to adjust the moisture to 60%; the material is sent to solar bio-fermentation The U-shaped trough of the trough is fermented once, and the material turning and throwing machine is started to work, and the air supply fan is turned on at the same time to supply air. The materials in the U-shaped trough are turned once a day, and the fermentation is continuous for 10 days. The gas generated during the fermentation passes through the gas collection pipe. Introduce a gas purification device; the U-shaped material tank of the solar biological fermentation tank is discharged into the U-shaped tank of the solar biological post-ripening tank for secondary post-ripening fermentation; the material turning and throwing machine is started, and the air su...

Embodiment 2

[0048] Livestock and poultry manure is dehydrated by solid-liquid separation, controlling the moisture content to 75%, adding 30% crushed tobacco powder by weight, and then adding high-efficiency microbial fermentation agent Bacillus subtilis to adjust the moisture content to 65%; The U-shaped trough of the solar bio-fermentation tank is fermented once, the material turning and throwing machine is started, and the air supply fan is turned on at the same time. The materials in the U-shaped trough are turned once a day, and the fermentation is continuous for 8 days. The gas generated during the fermentation passes through The gas collection pipeline is introduced into the gas purification device; the U-shaped material tank of the solar biological fermentation tank is discharged into the U-shaped tank of the solar biological post-ripening tank for secondary post-ripening fermentation; the material turning machine is started, and the gas supply fan is turned on at the same time , t...

Embodiment 3

[0050] Livestock and poultry manure is dehydrated by solid-liquid separation, controlling the moisture content to 75%, adding crushed traditional Chinese medicine residue with a weight ratio of 30%, and then adding high-efficiency microbial fermentation agent yeast to adjust the moisture content to 60%; the material is sent to the solar biological The U-shaped trough of the fermentation tank is fermented once, the material turning and throwing machine is started, and the air supply fan is turned on at the same time. The materials in the U-shaped trough are turned over once a day, and the fermentation is continuous for 10 days. The gas generated during the fermentation is collected by the gas. The pipeline is introduced into the gas purification device; the U-shaped material tank of the solar biological fermentation tank is discharged into the U-shaped tank of the solar biological post-ripening tank for secondary post-ripening fermentation; the material turning and throwing machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com