Preparation method of ozone oxidation catalyst for removing organic matters and total nitrogen in water

A technology of ozone oxidation and organic matter, applied in the field of environmental sewage treatment, can solve the problems of secondary pollution of iron sludge, low efficiency of ozone alone, large dosage, etc., achieve strong adsorption performance, improve wastewater biodegradability, toxicity and total The effect of nitrogen content reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Modification of catalyst support: with 500g aluminum hydroxide powder as raw material, with one or more mixtures in polyethylene glycol, sodium bicarbonate, glucose as pore-forming agent, ultrapure water as binding agent, Preparation of γ-Al with a diameter of 3-5 mm 2 o 3 ball carrier.

[0032] (2) Preparation of immersion solution: 74.7 g of cobalt acetate tetrahydrate and 51.6 g of cerium acetate were used as active component precursors, and 1 L of water was used as a solvent to prepare the immersion solution.

[0033] (3) Preparation of catalyst: 500g of γ-Al prepared in step (1) 2 o 3 Place in the impregnating solution obtained in step (2), shake and adsorb for 1-10 hours; filter and dry in an oven at 105°C, place in a muffle furnace, heat up to 600°C at a heating rate of 200°C / h, and calcine at a constant temperature for 6 hours After the reaction to generate oxides, that is, the catalyst.

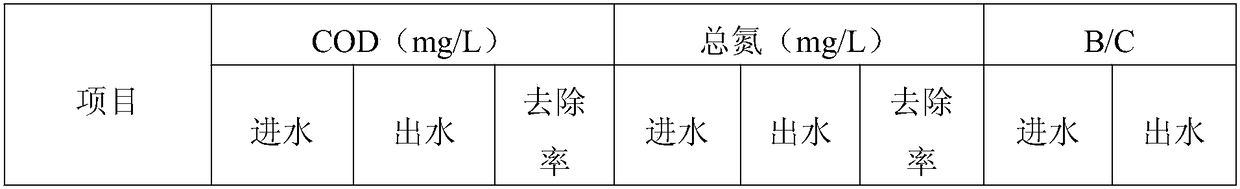

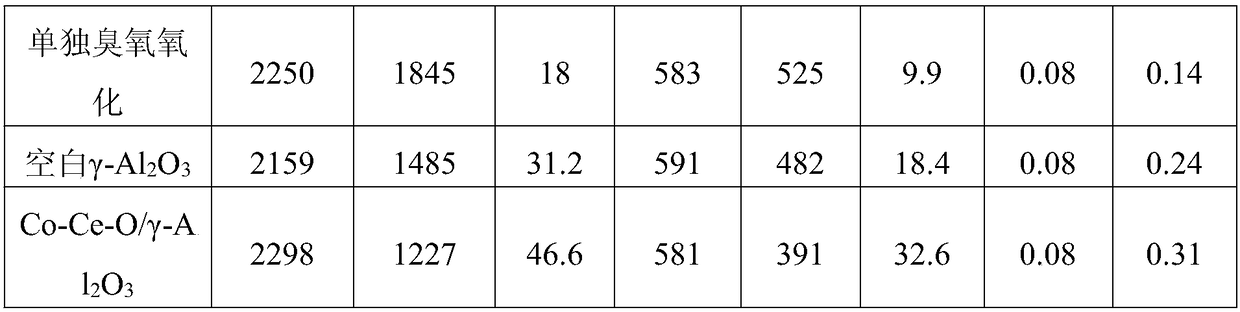

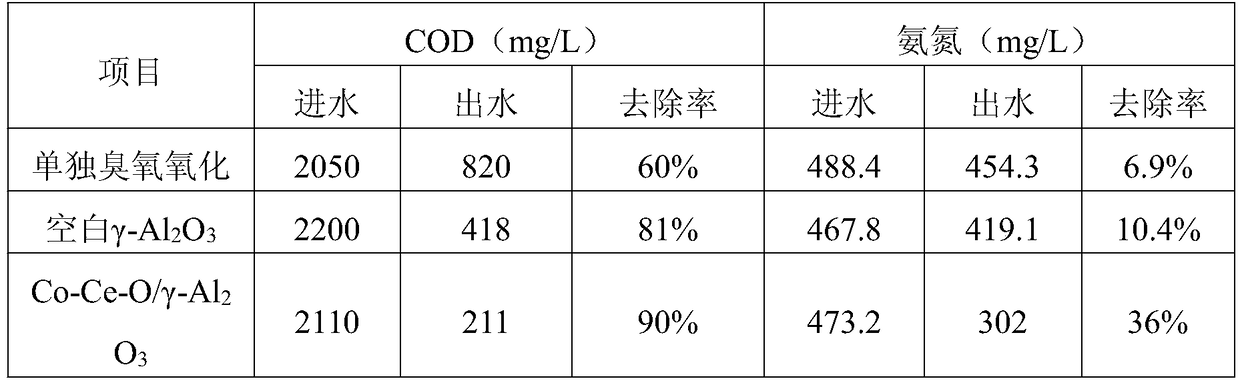

[0034] According to the characteristics of high salt, organic ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com