Culture pond system realizing rotational-flow dirt collection

A breeding pond and flow collection technology, which is applied in the field of breeding pond systems, can solve the problems of large interference of aeration facilities on water flow, unfavorable water body flow and water circulation, unfavorable water discharge and circulation, etc., so as to improve the effect of sewage collection and avoid pollution. Water layer exchange, ease of difficulty and effects of water volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

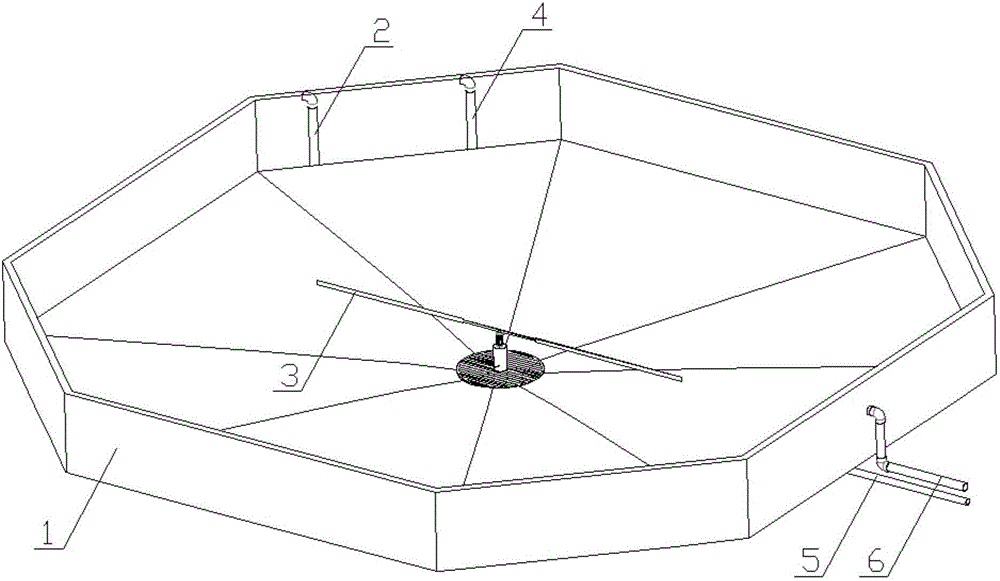

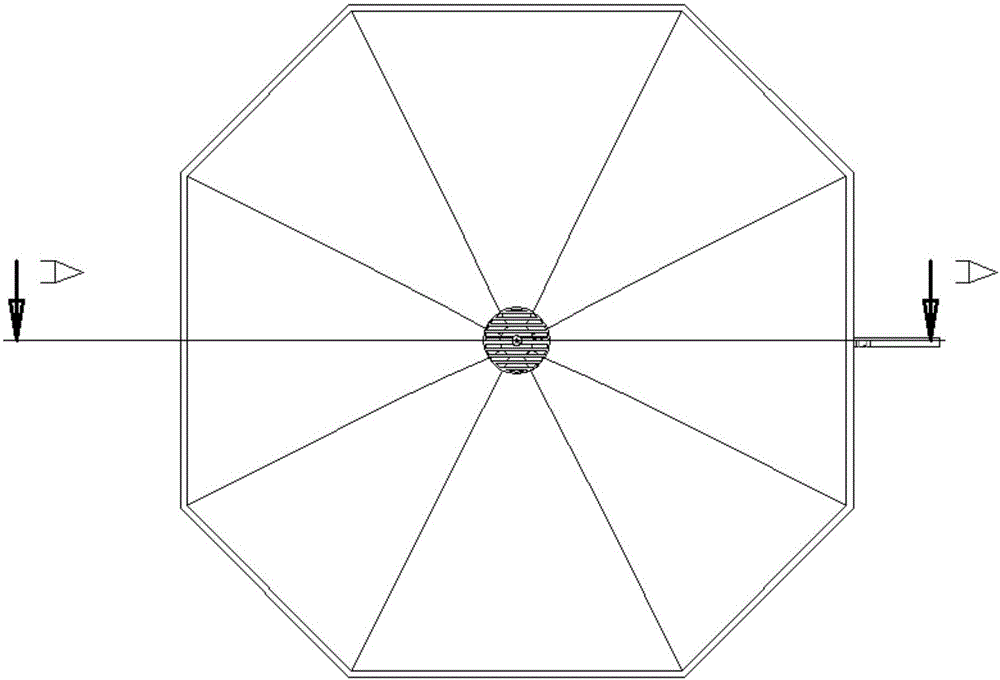

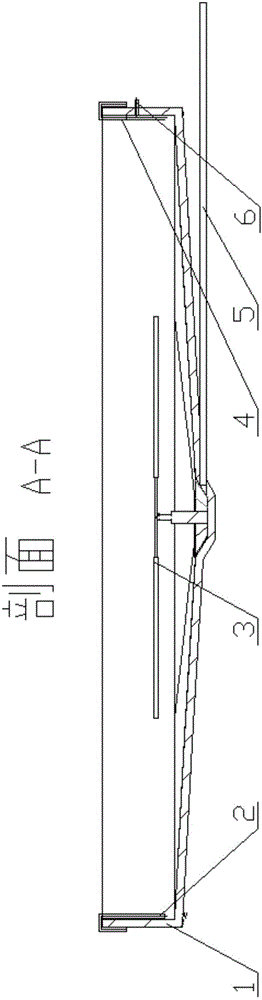

[0033] see Figure 1-Figure 4 , a culture pond system for swirl sewage collection, comprising a circular or regular polygonal pool body 1, the center of the pool body 1 has a certain taper downward; the bottom of the pool body 1 is provided with a swirl flow sewage collection device 3 , the swirling sewage collection device 3 has a motor 303, the motor 303 drives the horizontal support rod 302 to rotate, and the end of the support rod 302 is connected to the propeller 301; the direction of the swirling flow generated by the propeller 301 is vertically downward, and the propeller The distance between 301 and the bottom of the pool is less than 1 meter; a support column 304 is provided below the motor 303, and the support column 304 is fixedly connected with the dirt collection tank 305, and the dirt collection tank 305 collects fixed particles, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com