Nitrated carbon fiber loaded bismuth oxyhalide nanoflower and preparation method of nanoflower

A technology of bismuth oxyhalide and carbon fiber, which is applied in the environmental protection field of photocatalytic degradation of organic pollutants, can solve problems such as secondary pollution, and achieve the effects of repeated use, simple synthesis method, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Measure two parts of 40ml ethylene glycol methyl ether and join in the beaker, take by weighing 1.03g ionic liquid (C 16 MimCl) and 0.97g bismuth nitrate are added to above-mentioned solution respectively, constantly stirring makes two kinds of materials be fully dissolved in the ethylene glycol methyl ether, forms uniform solution, then the ethylene glycol methyl ether solution of ionic liquid is slowly added to In the bismuth nitrate ethylene glycol methyl ether solution, stir for 20 minutes to make the solution uniform. Pour the mixed solution into a polytetrafluoroethylene-lined autoclave with a volume of 100ml, then place the nitric acid-treated carbon fiber in the autoclave, react at 160°C for 1 hour, cool at room temperature, and wash with deionized water and absolute ethanol The samples were washed three times and dried for 12 hours to obtain the product BiOCl / ACF.

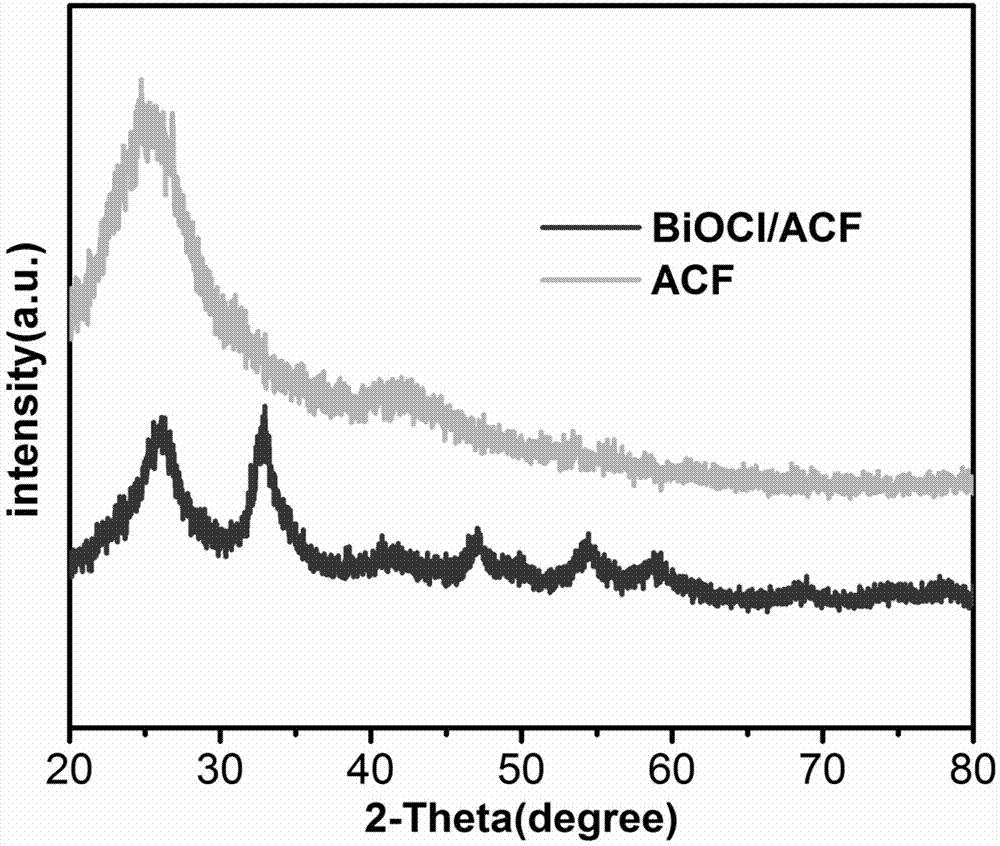

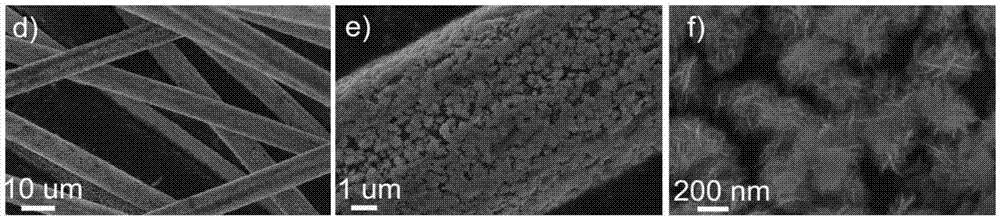

[0030] attached figure 1 (red, green) are respectively the X-ray diffraction pattern of the pr...

Embodiment 2

[0032] Measure two parts of 40ml ethylene glycol methyl ether and join in the beaker, weigh 1.16g ionic liquid (C 16 MimBr) and 0.97g bismuth nitrate are added to above-mentioned solution respectively, constantly stirring makes two kinds of materials be fully dissolved in the ethylene glycol methyl ether, forms uniform solution, then the ethylene glycol methyl ether solution of ionic liquid is slowly added to In the bismuth nitrate ethylene glycol methyl ether solution, stir for 20 minutes to make the solution uniform. Pour the mixed solution into a polytetrafluoroethylene-lined autoclave with a volume of 100ml, then place the nitric acid-treated carbon fiber in the autoclave, react at 160°C for 1 hour, cool at room temperature, and wash with deionized water and absolute ethanol The samples were washed three times and dried for 12 hours to obtain the product BiOBr / ACF.

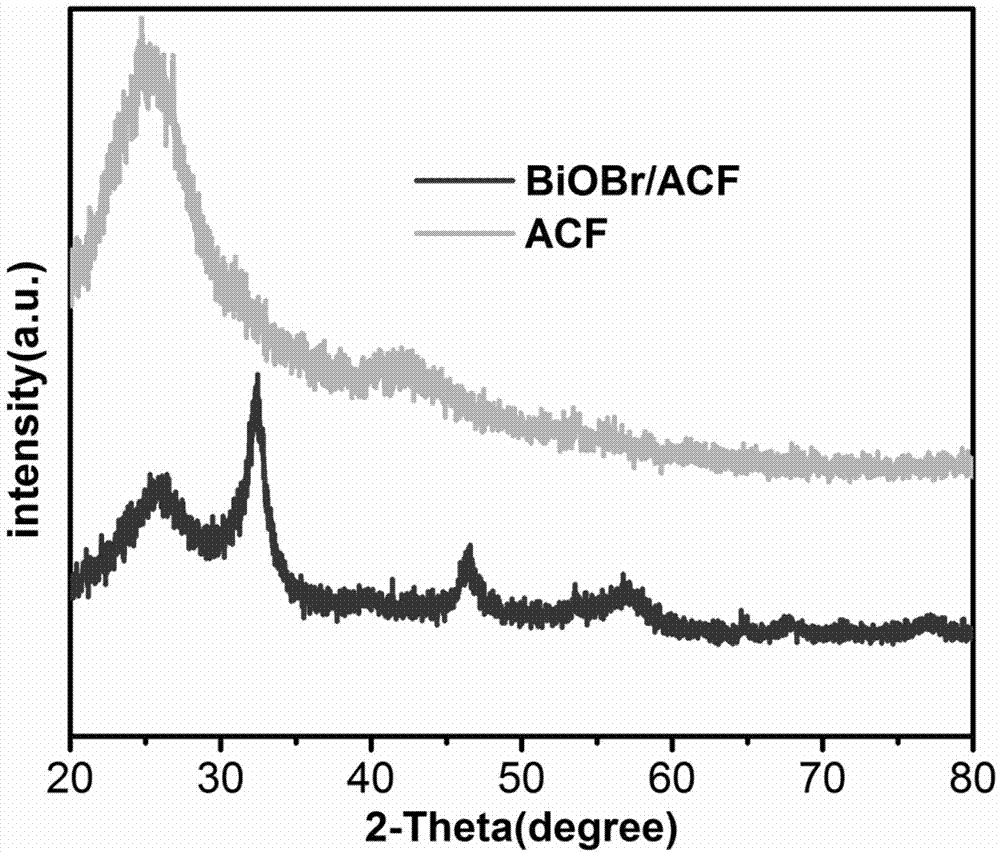

[0033] attached image 3 (red, green) are the X-ray diffraction pattern of the product obtained in this e...

Embodiment 3

[0035] Measure two parts of 30ml ethylene glycol methyl ether and join in the beaker, weigh 0.77g ionic liquid (C 16 MimCl) and 0.73g bismuth nitrate are added to above-mentioned solution respectively, constantly stirring makes two kinds of materials be fully dissolved in the ethylene glycol methyl ether, forms uniform solution, then the ethylene glycol methyl ether solution of ionic liquid is slowly added to In the bismuth nitrate ethylene glycol methyl ether solution, stir for 20 minutes to make the solution uniform. Pour the mixed solution into a polytetrafluoroethylene-lined autoclave with a volume of 100ml, then place the nitric acid-treated carbon fiber in the autoclave, react at 160°C for 2 hours, cool at room temperature, and wash with deionized water and absolute ethanol The samples were washed three times and dried for 12 hours to obtain the product BiOCl / ACF.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com