Method for treating arsenic in nonferrous smelting waste acid by using magnetic Fe3O4

A dirty acid and magnetic technology, applied in the field of heavy metal arsenic pollution control, can solve the problems of inability to guarantee leaching toxicity and compliance, and achieve significant environmental and economic benefits, stable physical properties, and simple operating procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

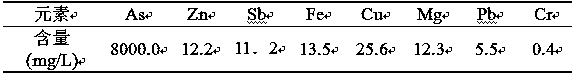

[0022] Example 1: The polluted acid in this example comes from the polluted acid containing a large amount of impurities such as arsenic, which is produced after the sulfuric acid workshop of a copper smelter in Southwest China washes the smelting flue gas. The main components are shown in Table 1;

[0023] Table 1 Concentration of various components of polluted acid

[0024]

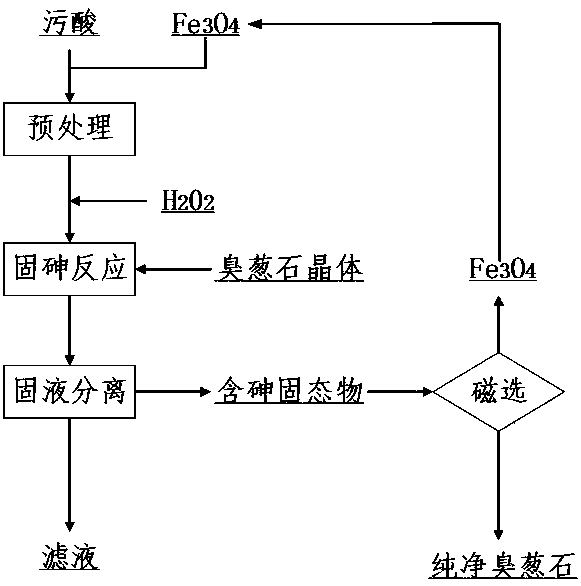

[0025] Such as figure 1 As shown, a magnetic Fe 3 o 4 The method for treating the arsenic in the waste acid of non-ferrous smelting, the specific steps are as follows:

[0026] (1) The magnetic Fe 3 o 4 Mix well with dirty acid and pretreat for 12 hours under stirring conditions to obtain solution A, then add H to solution A 2 o 2 and scorodite crystals, mix uniformly to obtain solution B; wherein the arsenic content of dirty acid is 8000mg / L, and the magnetic Fe 3 o 4 The molar ratio of the iron in the iron to the arsenic in the dirty acid is 2:1, the molar ratio of the scorodite crystals to...

Embodiment 2

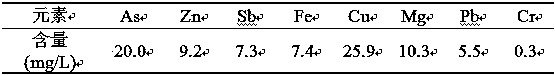

[0031] Example 2: The polluted acid in this example comes from the polluted acid containing a large amount of impurities such as arsenic, which is produced after the sulfuric acid workshop of a zinc smelter in Southwest China washes the smelting flue gas. The main components are shown in Table 3;

[0032] Table 3 Concentration of each component of polluted acid

[0033]

[0034] Such as figure 1 As shown, a magnetic Fe 3 o 4 The method for treating the arsenic in the waste acid of non-ferrous smelting, the specific steps are as follows:

[0035] (1) The magnetic Fe 3 o 4 Mix well with dirty acid and pretreat for 18 hours under stirring conditions to obtain solution A, then add H to solution A 2 o 2 and scorodite crystals, mix evenly to obtain solution B; wherein the arsenic content of dirty acid is 10000mg / L, and the magnetic Fe 3 o 4 The molar ratio of the iron in the iron to the arsenic in the dirty acid is 2.5:1, the molar ratio of the scorodite crystals to the a...

Embodiment 3

[0040] Embodiment 3: The polluted acid in this example comes from the polluted acid containing a large amount of impurities such as arsenic produced after the sulfuric acid workshop of a copper smelter in Southwest China washes the smelting flue gas. The main components are shown in Table 5;

[0041] Table 5 Concentration of various components of polluted acid

[0042]

[0043] Such as figure 1 As shown, a magnetic Fe 3 o 4 The method for treating the arsenic in the waste acid of non-ferrous smelting, the specific steps are as follows:

[0044] (1) The magnetic Fe 3 o 4 Mix evenly with dirty acid and pretreat for 24 hours under stirring conditions to obtain solution A, then add H to solution A 2 o 2 and scorodite crystals, mix uniformly to obtain solution B; wherein the arsenic content of dirty acid is 13000mg / L, and the magnetic Fe 3 o 4 The molar ratio of the iron in the iron to the arsenic in the dirty acid is 3:1, the molar ratio of the scorodite crystals to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com