Method for obtaining high-leaching stability scorodite by precipitating arsenic-containing solution

A scorodite, stable technology, applied in chemical instruments and methods, inorganic chemistry, iron compounds, etc., to achieve the effects of low equipment requirements, easy solid-liquid separation, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

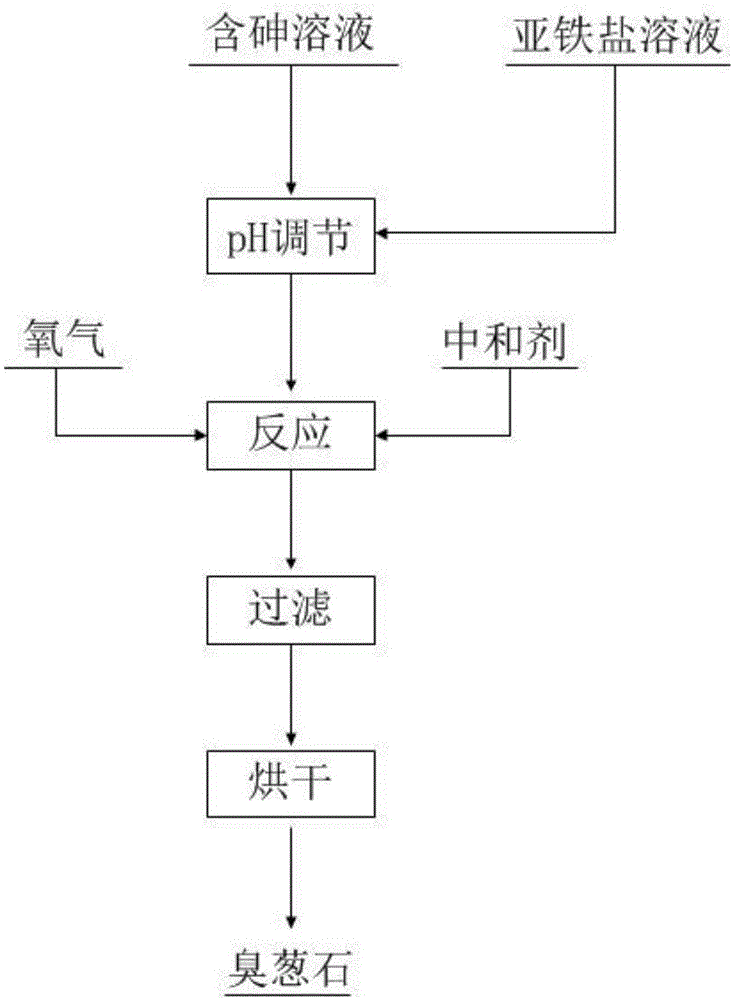

Method used

Image

Examples

Embodiment 1

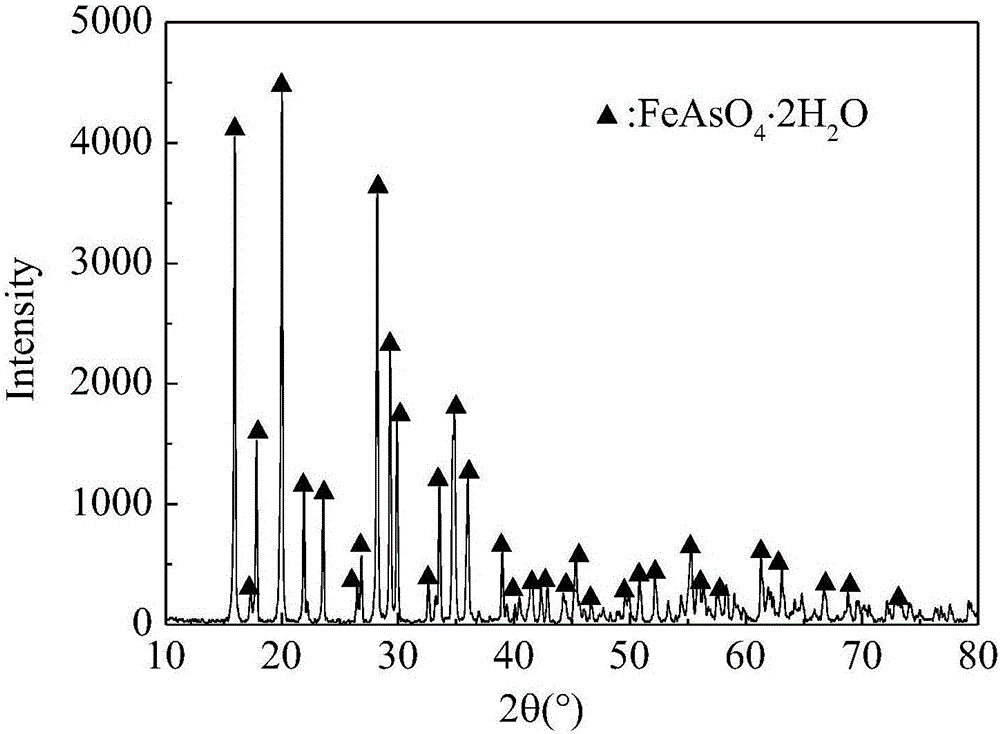

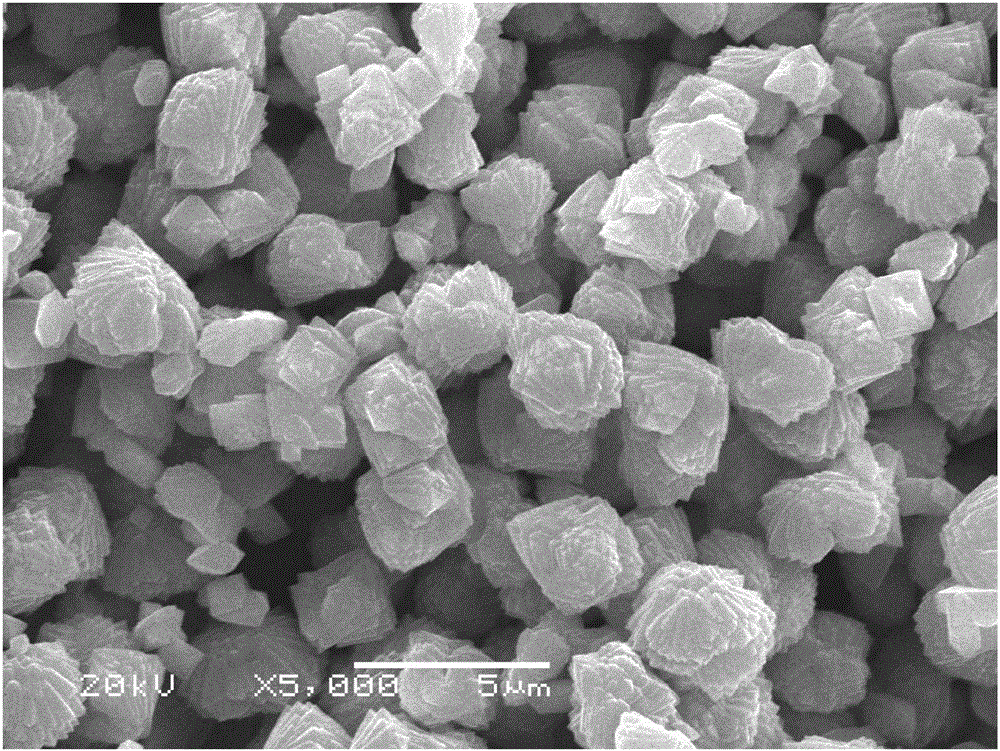

[0031] Preparation of scorodite

[0032] Take 100g of arsenic trioxide, add 200g of hydrogen peroxide solution with a mass fraction of 30%, add distilled water to 500ml, heat and boil until the solid particles are completely dissolved, then continue to boil for 2h, titrate the concentration of trivalent arsenic ions in it by titration, if There is also trivalent arsenic, then continue heating until all trivalent arsenic is oxidized to pentavalent. Add water to make up the volume until the concentration of arsenic is 30g / L, and measure it by ICP-AES, the obtained solution is 30g / L arsenic acid solution.

[0033] Take 250ml of the 30g / L arsenic acid solution prepared by the above method, adjust the pH value to 1.5 with NaOH, preheat to 90°C, and stir; add ferrous salt solution and neutralizing agent sodium carbonate solution to it at the same time to control the reaction system The molar ratio of Fe / As in the medium is 2:1, and concentrated H 2 SO 4 Adjust the pH to 1.5. Whe...

Embodiment 2

[0039] Preparation of scorodite

[0040] Scoorite was prepared according to the method of Example 1, wherein the concentration of arsenic acid was 40 g / L, and other conditions remained unchanged, and scorodite powder with good crystallization state was obtained.

[0041] toxic leaching

[0042](1) Carry out toxic leaching in accordance with GB5085.3-2007 (identification standard for solid waste—identification of leaching toxicity), the leaching concentration of arsenic is 0.15mg / L, which is less than the limit of the standard, and can be safely and stably stored;

[0043] (2) According to the liquid-solid mass ratio of 20:1, mix 1g of scorodite powder prepared above with 20ml of NaOH+CaO mixed solution with a pH value of 9.67, leaching for 40 days at 25°C, and measure the content of arsenic in it. The leaching concentration is 0.26mg / L.

Embodiment 3

[0045] Preparation of scorodite

[0046] Scoorite was prepared according to the method of Example 1, wherein the concentration of arsenic acid was 70 g / L, and other conditions remained unchanged, and scorodite powder with good crystallization state was obtained.

[0047] toxic leaching

[0048] (1) Toxic leaching is carried out according to GB5085.3-2007 (Standard for identification of solid waste - identification of leaching toxicity), the leaching concentration of arsenic is 0.20mg / L, which is less than the limit value of this standard, and it can be stored safely and stably;

[0049] (2) According to the liquid-solid mass ratio of 20:1, mix 1g of scorodite powder prepared above with 20ml of NaOH+CaO mixed solution with a pH value of 9.67, leaching for 40 days at 25°C, and measure the content of arsenic in it. The leaching concentration is 0.30mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com