Immobilization method of arsenic in arsenic-containing solution

A solution and content technology, applied in the field of pollutant treatment, can solve the problems of many operation steps, difficult filtration and separation of mixed precipitation, incomplete iron precipitation, etc., and achieves the effect of high purity, accelerated oxidation speed, and reduction of acid used for solution acidification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

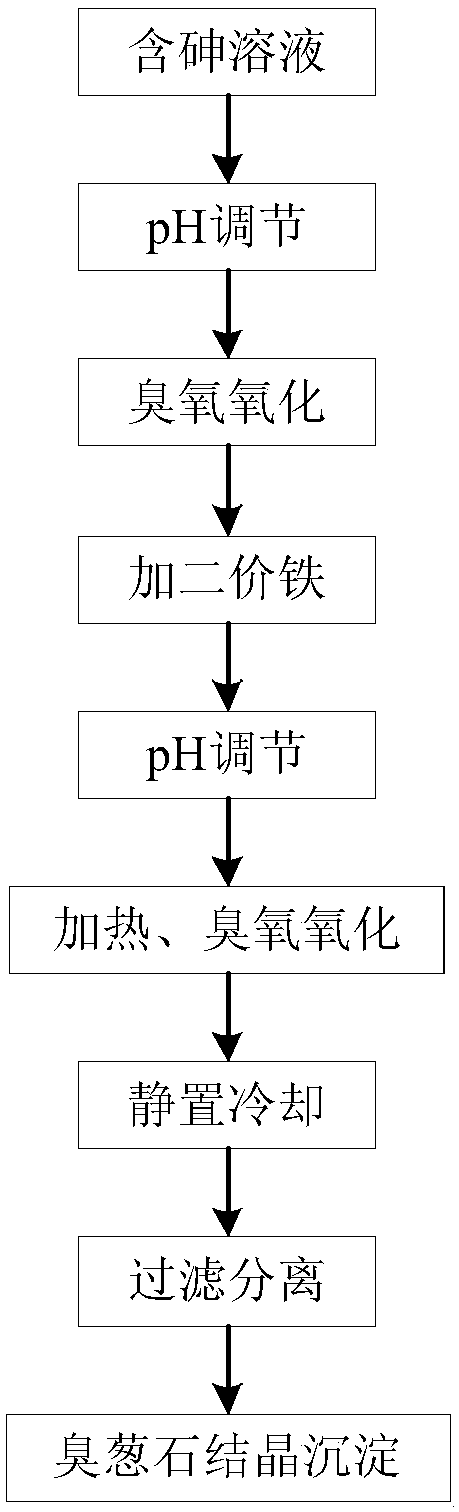

[0056] This embodiment provides a method for immobilizing arsenic in an arsenic-containing solution, the method comprising the following steps:

[0057] (1) Sodium arsenite and ferric sulfate were dissolved in water to prepare a solution with arsenic and iron concentrations of 1g / L, to simulate arsenic-containing drainage in mines, take 1L of the solution, adjust the pH to 1.0 with sulfuric acid, and add to the solution The ozone-containing gas prepared by an ozone generator using air as a raw material is passed into the medium, and the ozone concentration is 40mg / L, and the gas is ventilated for 1h under stirring conditions, and the trivalent arsenic is oxidized to pentavalent arsenic to obtain a solution containing pentavalent arsenic ;

[0058] (2) Add ferrous sulfate heptahydrate to the solution obtained in step (1), so that the mol ratio of iron and arsenic in the solution is 1.5:1, stir and dissolve and then heat up to 90°C, and then feed the gas with an ozone concentrat...

Embodiment 2

[0061] This embodiment provides a method for immobilizing arsenic in an arsenic-containing solution, the method comprising the following steps:

[0062] (1) A bioleaching waste liquid of arsenic-containing gold concentrate, wherein the concentration of arsenic is 2.8g / L, the concentration of iron is 3.6g / L, and the initial pH is 1.2. Get 1L of this solution, and pass into it by ozone The generator uses air as the raw material to produce ozone-containing gas, in which the ozone concentration is 80mg / L, and it is ventilated for 2 hours under stirring conditions to oxidize trivalent arsenic to pentavalent arsenic to obtain a solution containing pentavalent arsenic;

[0063] (2) Add ferrous chloride tetrahydrate to the solution that step (1) obtains, make the mol ratio of iron and arsenic in the solution be 2:1, be warming up to 85 ℃ after stirring and dissolving, pass into ozone concentration again and be 80mg / L Gas, ferrous iron is oxidized to ferric iron, ferric iron reacts wit...

Embodiment 3

[0066] This embodiment provides a method for immobilizing arsenic in an arsenic-containing solution, the method comprising the following steps:

[0067] (1) A kind of arsenic-containing waste residue leaching solution produced by copper smelting, wherein the concentration of arsenic is 6g / L, the concentration of iron is 0.5g / L, and the initial pH is 1.0. Take 1L of this solution and pass it into it by an ozone generator Ozone-containing gas prepared from oxygen as a raw material, wherein the ozone concentration is 120 mg / L, is aerated for 3 hours under stirring conditions, and trivalent arsenic is oxidized to pentavalent arsenic to obtain a solution containing pentavalent arsenic;

[0068] (2) add ferrous sulfate to the solution that step (1) obtains, make the mol ratio of iron and arsenic in the solution be 1:1, be warming up to 95 ℃ after stirring and dissolving, pass into the gas that ozone concentration is 120mg / L again, will Ferrous iron is oxidized to ferric iron, and fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com