Adhesive sheet, upper electrode for touch panel, and image display device

A touch panel and adhesive sheet technology, which can be used in identification devices, film/sheet-like adhesives, applications, etc., can solve problems such as obstacles to the thinning of image display devices, and achieve excellent adhesion durability and operability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0299] (1) Preparation of coating solution for forming hot water-resistant adhesiveness improving layer (E)

[0300] [Preparation of water-dispersible copolyester resin]

[0301] A water-dispersible copolyester was synthesized by using a pressurized esterification reaction tank with a distillation tower and two polycondensation reaction tanks with a vacuum generating device, using antimony trioxide as a polycondensation catalyst in batches.

[0302] The copolymerization composition of the water-dispersible copolyester is terephthalic acid / isophthalic acid / 5-sodiumsulfoisophthalic acid / / neopentyl glycol / ethylene glycol=50 / 43 / 7 / / 70 / 30 (molar ratio), the reduced viscosity is 0.68dl / g.

[0303] 〔Preparation of coating liquid〕

[0304] 100 parts of the crushed product of the above-mentioned water-dispersible copolyester was converted into a water dispersion by a predetermined method. With respect to 100 parts of the solid content of the aqueous dispersion, 5 parts of methylolate...

reference example 1

[0360] In the method of Example 1, except that the coating solution for forming the hot water-resistant adhesiveness improving layer (E) was changed to 8 parts of silicone ("KS-744"; manufactured by Shin-Etsu Chemical Co., Ltd.) and 0.06 parts of catalyst " Except that PL-3" (manufactured by Shin-Etsu Chemical Co., Ltd.) was dissolved in 100 parts by mass of toluene, a protective film for a display screen was obtained in the same manner as in Example 1. The evaluation results are shown in Table 1.

[0361] In the protective film for a display screen obtained in Reference Example 1, the silicone rubber adhesive layer (B) and the polyester-based base film (A) had poor hot water-resistant adhesiveness and were of low quality.

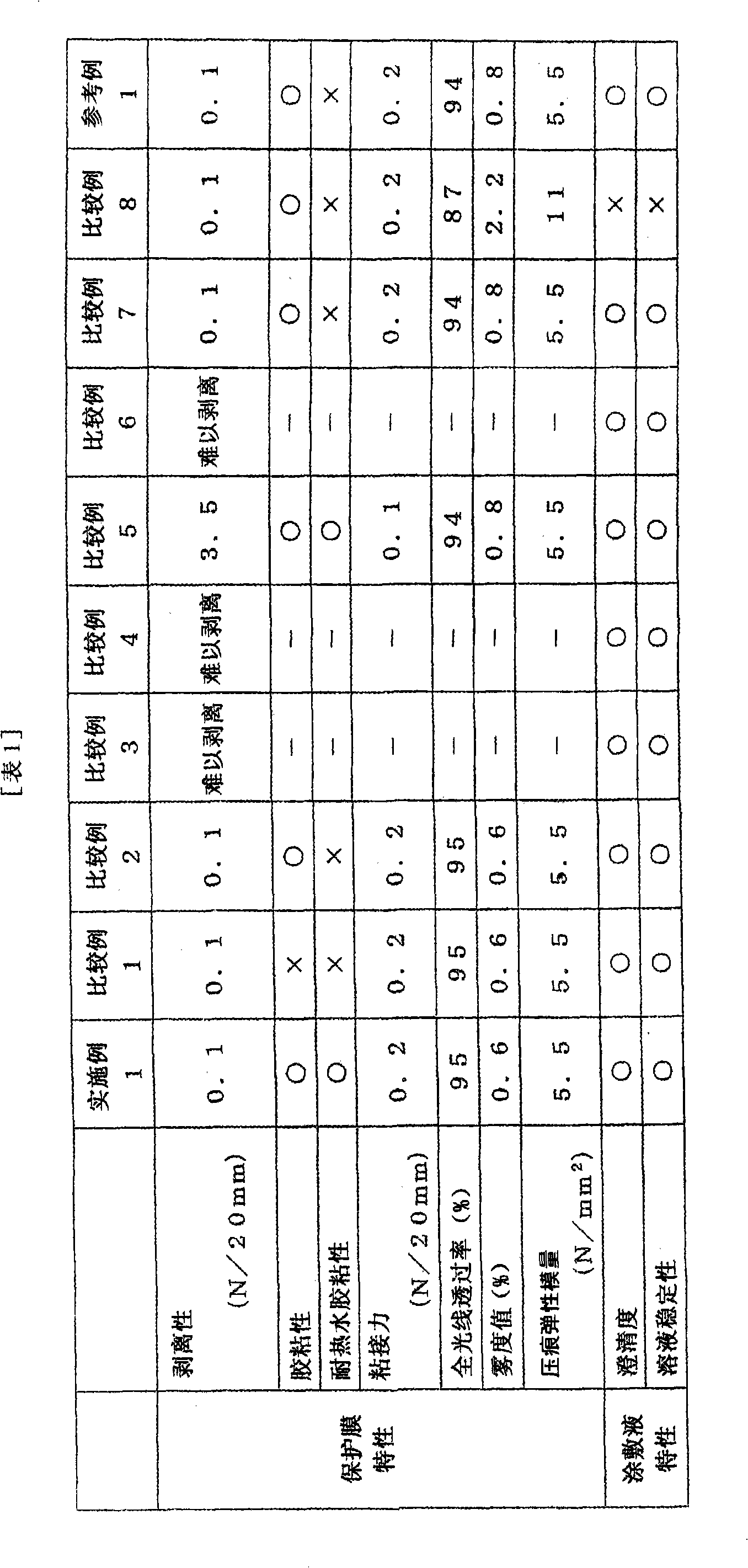

[0362] [Table 1]

[0363]

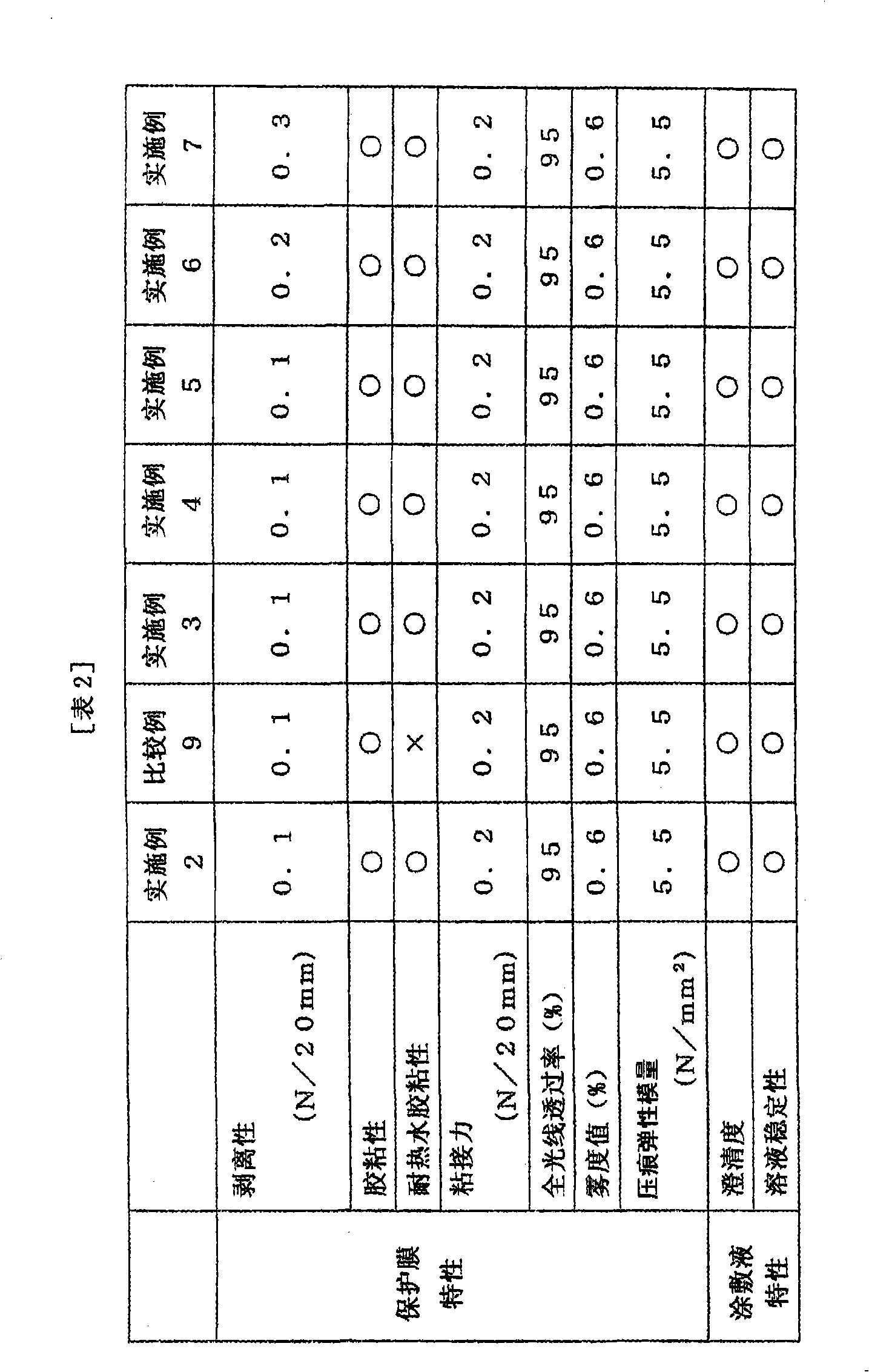

Embodiment 2

[0365] During the manufacture of the polyester base film (A) of Example 1, except that the coating of the coating liquid (E-1) was cancelled, the polyester base film (A-1) was obtained in the same manner as in Example 1. 2). Corona treatment was given to both surfaces of this polyester base film (A-2). In addition, a copolyester resin solution (“Bairon (registered trademark) 30SS”; manufactured by Toyobo Co., Ltd.) and a polyisocyanate-based crosslinking agent (“Coronet ( Registered trademark) HX"; Nippon Polyurethane Co., Ltd.), to prepare a coating solution (E-2) for the hot water-resistant adhesiveness improvement layer (E). This coating solution (E-2) was applied to both surfaces of the corona-treated polyester base film (A-2) using an applicator, and dried. A laminate in which the crosslinked hot water-resistant adhesiveness-improving layer (E-2) was laminated on both surfaces of the polyester-based base film (A-2) was obtained. Using this laminate, a protective film f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com