Clear sugar-free tartary buckwheat tea and production method thereof

A kind of sugar tartary buckwheat tea and the technology of production method, which is applied in the field of food processing, can solve the problems such as the patent literature and non-patent literature reports of liquid tartary buckwheat tea, and achieve the effects of clarification, long shelf life, and nutritional content retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

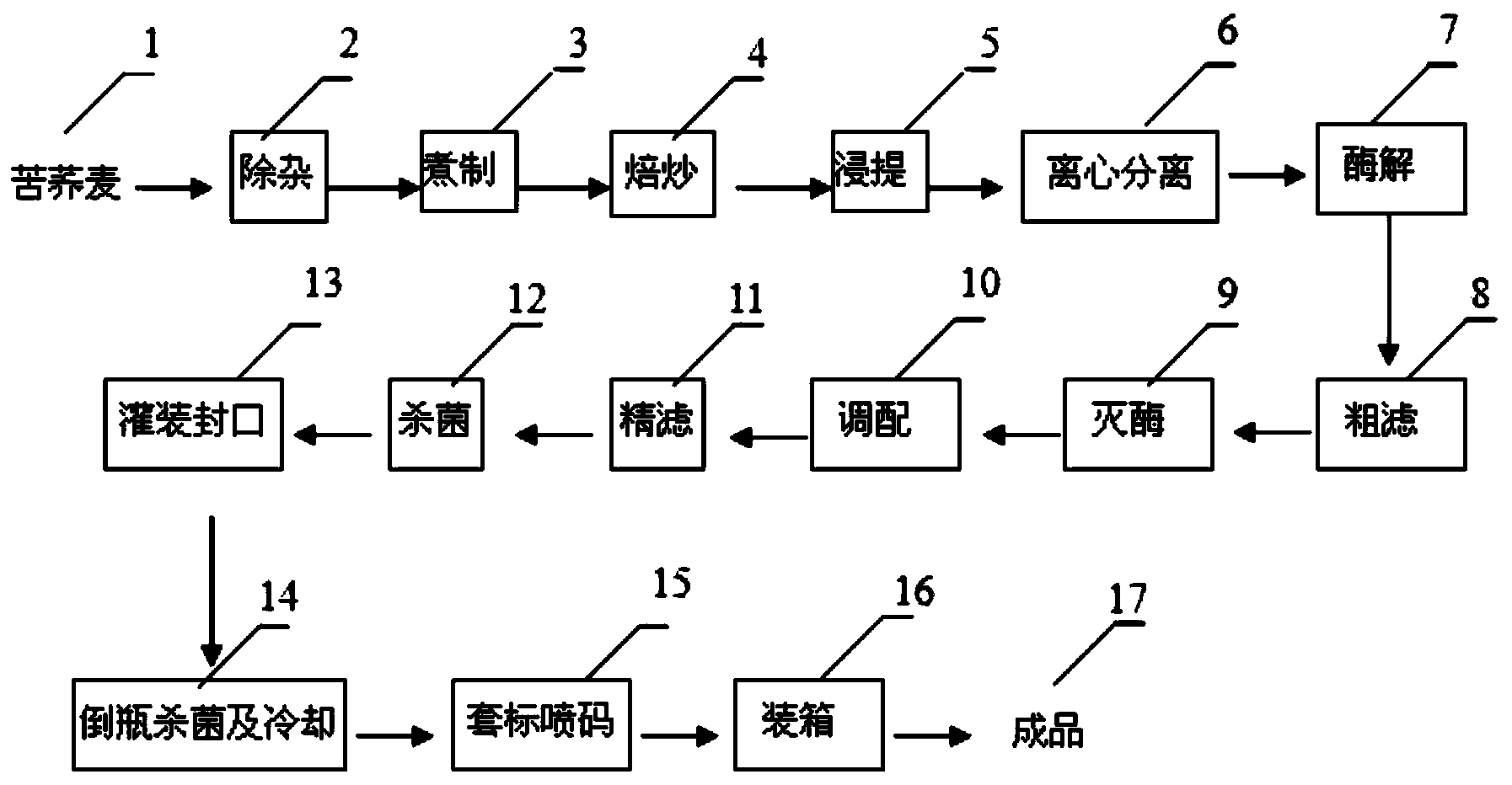

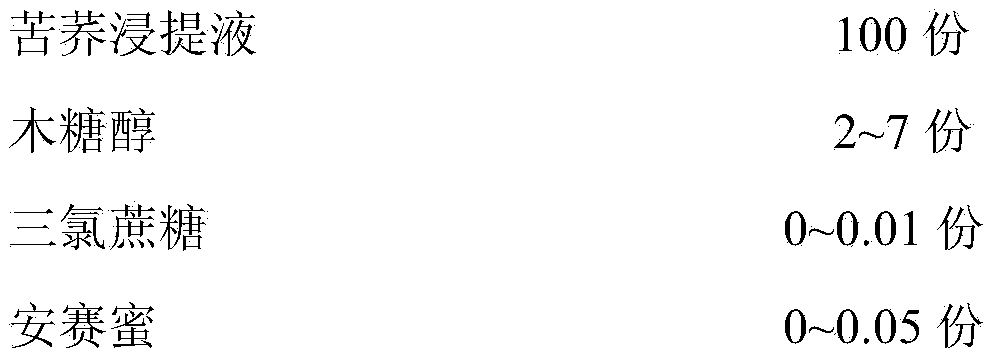

[0054] The tartary buckwheat with skin of good quality is removed from the impurities by winnowing machine, vibrating screen, specific gravity sorting machine and magnetic sorting machine; put the tartary buckwheat in boiling water and cook for 5 minutes, remove and drain; add the clean sand into the frying pan Or heat the temperature to 200°C in a rotary frying furnace, then add tartary buckwheat after removing impurities and roast together for 20 minutes; sieve and separate to obtain roasted tartary buckwheat; Ratio, Stir and extract at a temperature of 93°C for 30 minutes; pump the extract into a centrifuge for centrifugation, and pump the centrifuge into an insulated enzymolysis tank; add 0.1 part of α-amylase to 1000 parts of the centrifuge, Insulate and stir for 40 minutes for enzymolysis; use a bag filter to remove the precipitate in the enzymolysis tartary buckwheat liquid, the filter bag has a pore size of 0.8 μm; pump the coarsely filtered tartary buckwheat liquid int...

Embodiment 2

[0056] The tartary buckwheat with skin of good quality is removed from the impurities by winnowing machine, vibrating screen, specific gravity sorting machine and magnetic sorting machine; put tartary buckwheat in boiling water and cook for 10 minutes, remove and drain; add clean sand into the frying pan Or heat up to 230°C in a rotary frying furnace, then add tartary buckwheat after removing impurities and roast together for 10 minutes; sieve and separate to obtain roasted tartary buckwheat; add roasted tartary buckwheat into the extraction tank, and use a material-to-liquid ratio of 1:50 Stir and extract at a temperature of 98°C for 20 minutes; pump the extract into a centrifuge for centrifugation, and pump the centrifuge into an insulated enzymolysis tank; add 0.05 parts of α-amylase to 1000 parts of the centrifuge, and keep stirring at a temperature of 55°C Enzymatic hydrolysis for 80 minutes; use bag filter to remove the precipitate in the enzymatic tartary buckwheat solut...

Embodiment 3

[0058] Good-quality tartary buckwheat with skin, remove the impurities in it through winnowing machine, vibrating screen, specific gravity sorting machine and magnetic sorting machine; add tartary buckwheat into boiling water and cook for 7 minutes, remove and drain; add clean sand to frying pan Or heat the temperature to 210°C in a rotary frying furnace, then add tartary buckwheat after removing impurities and roast together for 17 minutes; sieve and separate to obtain roasted tartary buckwheat; Ratio, stir and extract at a temperature of 95°C for 25 minutes; pump the extract into a centrifuge for centrifugation, and pump the centrifuge into an insulated enzymolysis tank; add 0.06 parts of α-amylase to 1000 parts of the centrifuge, Insulate and stir for 70 minutes of enzymolysis; use a bag filter to remove the precipitate in the enzymolysis tartary buckwheat liquid; the pore size of the filter bag is 1 μm; pump the coarsely filtered tartary buckwheat liquid into a heat exchang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com