Anti-deterioration cellar mud and preparation method thereof

A pit mud and formula technology, which is applied in the directions of biochemical equipment and methods, preparation of alcoholic beverages, and methods based on microorganisms, can solve the problem of insufficient moisture, nutrients, and caproic acid bacteria, and it is difficult to control pit mud and artificial pit mud. prone to degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the above-mentioned anti-degeneration pit mud comprises the following steps:

[0026] A. Finely crush the yellow clay and lay it flat on the production site, evenly sprinkle boiling water and infiltrate it for 24 hours, requiring uniform infiltration;

[0027] B. Sprinkle peat on the soaked yellow clay and dig carefully. It is required to mix the yellow clay and peat evenly, and then sprinkle the boiled yellow water, wine tail, K 2 HPO 4 After the solution is mixed evenly, cover with plastic film and infiltrate for 20 hours;

[0028] C. Uncover the plastic film, evenly spread the pit mud, bean cake powder, Daqu powder, and double-wheel bottom grains on the soil soaked with various materials, and then dig the third time to ensure that the digging is thorough and even ;

[0029] D. Put the mud mixer in place, turn on the power button, and sprinkle the mixed culture solution of caproic acid bacteria, liquid pit mud, propionic acid bacteria liqu...

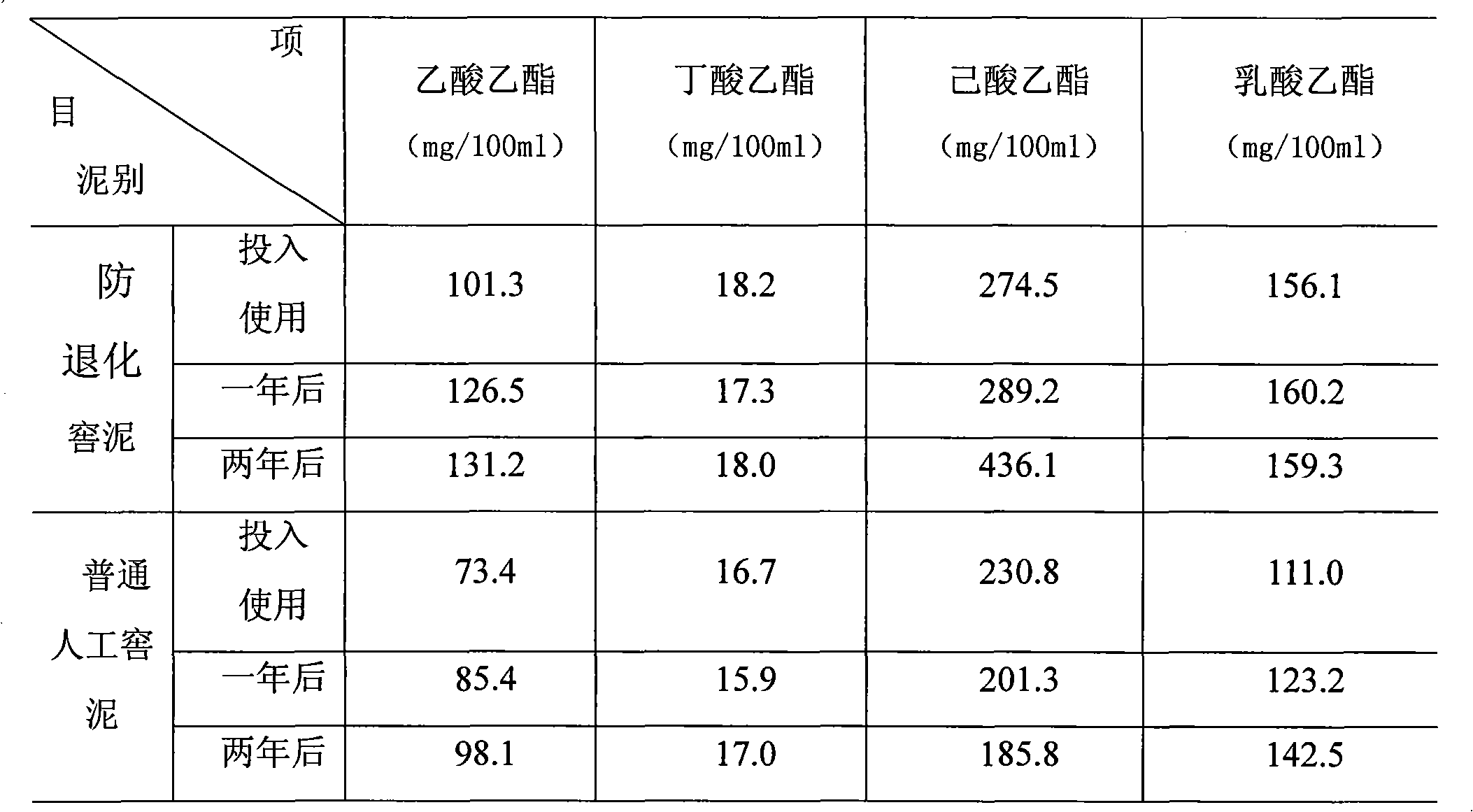

Embodiment 1

[0041] Recipe: base on yellow clay 1, Daqu powder: 3%, Shuanglun bottom fermented grains: 8%, mixed culture solution of caproic acid bacteria and liquid pit mud: 5%, M type microbial fermentation solution: 2%, peat: 15% %, pit mud (20 years of use): 5%, yellow water: 10%, propionic acid bacteria liquid: 1%, wine tail: 4%, bean cake powder: 2%, K 2 HPO 4 : 0.05%.

[0042] Preparation:

[0043] Finely crush the yellow clay and lay it flat on the production site, sprinkle boiling water evenly and infiltrate it for 24 hours, requiring uniform infiltration; spread peat on the infiltrated yellow clay and dig carefully, requiring yellow clay and peat to mix evenly, and then Sprinkle boiled yellow water, wine tail, K 2 HPO 4 After the solution is mixed evenly, cover with a plastic film and infiltrate for 20 hours; uncover the plastic film, spread the pit mud, bean cake powder, Daqu powder, and double-wheel bottom grain unstrained spirits evenly on the soil soaked with various mate...

Embodiment 2

[0045] Recipe: base on yellow clay 1, Daqu powder: 5%, double-wheel bottom fermented grains: 10%, mixed culture solution of caproic acid bacteria and liquid pit mud: 8%, M-type microbial fermentation solution: 3%, peat: 20% %, pit mud (24 years of use): 8%, yellow water: 12%, propionic acid bacteria liquid: 2%, wine tail: 6%, bean cake powder: 3%, K2 HPO 4 : 0.1%.

[0046] Preparation:

[0047] Finely crush the yellow clay and lay it flat on the production site, sprinkle boiling water evenly and infiltrate it for 24 hours, requiring uniform infiltration; spread peat on the infiltrated yellow clay and dig carefully, requiring yellow clay and peat to mix evenly, and then Sprinkle boiled yellow water, wine tail, K 2 HPO 4 After the solution is mixed evenly, cover with a plastic film and infiltrate for 20 hours; uncover the plastic film, spread the pit mud, bean cake powder, Daqu powder, and double-wheel bottom grain unstrained spirits evenly on the soil soaked with various mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com