High-quality artificial pit mud in Baijiu production and preparation method thereof

A kind of pit mud and artificial technology, which is applied in the field of high-quality artificial pit mud and its preparation in liquor production, can solve the problems of application limitations, achieve good economic and social benefits, short fermentation aging time, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

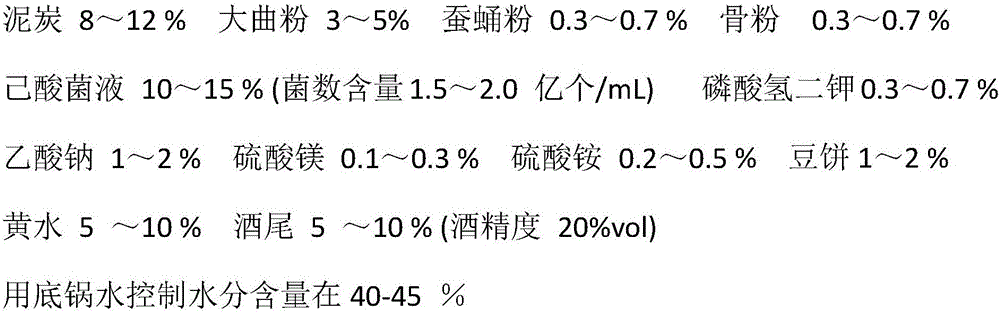

Method used

Image

Examples

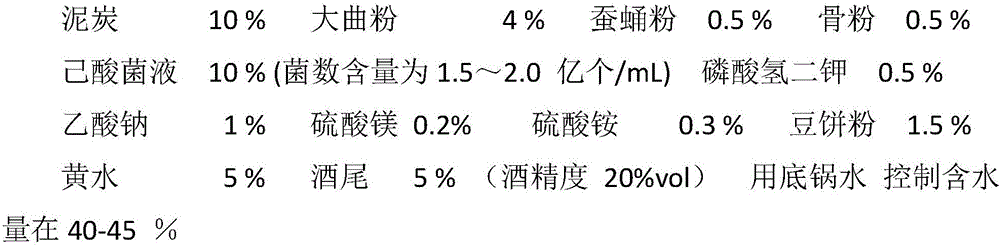

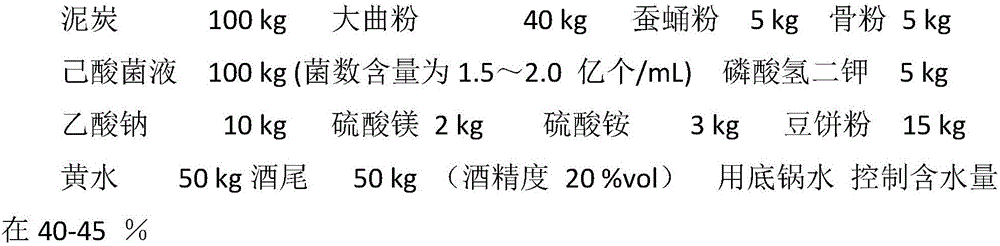

Embodiment 1

[0040] (1) Screen and weigh each formula component as required

[0041] Prepare mixed mud 1000kg (including loess 600kg, lotus pond mud 300kg, old cellar mud 100kg

[0042] On this basis, add the following substances in proportion:

[0043]

[0044] (2) Prepare high-quality artificial pit mud according to the aforementioned preparation steps.

[0045] (3) Natural fermentation culture of artificial pit mud

[0046] The artificial pit mud starts to ferment the next day, observe the fermentation situation, and make a record of the temperature of the fermentation tank. The temperature of the cellar pool is controlled at 30-35°C.

[0047] (2) The fermentation time is 50 days. The high-quality artificial pit mud tested after fermentation is taken out and put into production.

Embodiment 2

[0049] Use the fermented pit mud to build a pit in the koji wine workshop. After removing the bad grains from the cellar pool, clean the four walls, and paste the mature pit mud with a thickness of 15-20cm from the bottom, 15cm from the bottom, and 8cm from the top. Go up, and then produce raw wine on the basis of the original production process. The fermentation period is 60 days. The inspection results of the high-quality raw wine produced are as follows:

[0050] Table 1 The quality of liquor after using artificial high-quality pit mud

[0051]

[0052] It can be seen from Table 1 that after the use of artificial high-quality pit mud, the quality of the produced liquor remains stable after round rowing, and the concentration of ethyl hexanoate reaches 3.0g / above, which meets the standard of high-quality liquor and achieves the expected purpose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com