Method for producing fatty acid and device used therein

A fatty acid and anaerobic microorganism technology, applied in the field of microbial fermentation, can solve the problems of low microbial activity, high reactor operating cost, low utilization rate of synthesis gas, etc., and achieve the effects of reducing loss and improving mass transfer efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 utilizes the device of biomass fermentation to produce fatty acid

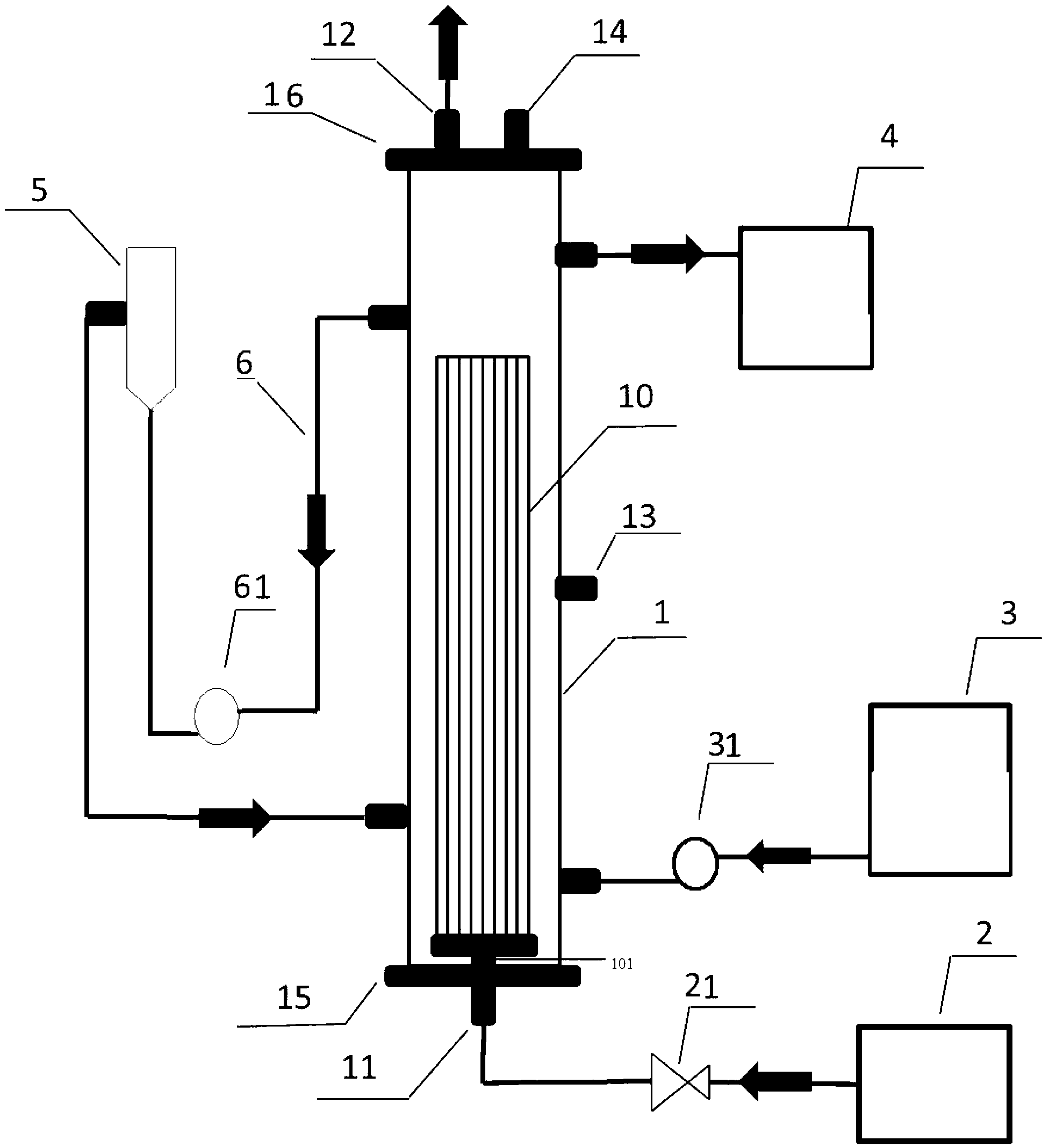

[0034] Such as figure 1 As shown, the present invention provides a kind of device of fatty acid production, comprises: the reactor 1 that hollow fiber membrane 10 is housed, and the synthetic gas supply device 2 that communicates with this reactor respectively, culture medium supply device 3, reactant reclaims The device 4 is a device 5 for measuring the pH value of the reaction system in the reactor; wherein, the reactor 1 is provided with an air inlet 11 and an air outlet 12 .

[0035] Wherein, the synthesis gas supply device 2 is provided with a pressure stabilizing valve 21 for controlling the pressure of the synthesis gas, and the device 2 is connected to the air inlet 11 ; the medium supply device 3 is provided with an inlet pump 31 .

[0036] In order to allow anaerobic microorganisms to better attach to the hollow fiber membranes and enhance the transfer between substances, the dev...

Embodiment 2

[0040] Example 2 Under neutral pH value and intermittent operation mode, a new method for producing fatty acid by indirect fermentation of biomass using mixed flora of hollow fiber membrane reactor.

[0041] The device used adopts the device in embodiment 1, such as figure 1 shown. In this embodiment, the hollow fiber membrane reactor 1 is made of organic glass. The shell has an inner diameter of 3.5cm and a height of 30cm. 1cm, 2cm, 14cm, 20cm, and 25cm from the lower end are respectively provided with 3 connection ports of the medium supply device, 6 water inlets of the reaction system circulation system, 13 sampling ports, 6 circulation ports of the reaction system circulation system and 4 connections of the reactant recovery device mouth. The hollow fiber membrane bundle 10 is made up of 30 polyethylene hollow fiber membranes. The effective length of the membranes is 22cm, the inner diameter is 1mm, and the outer diameter is 1.1mm. The air port 11 runs through. The sy...

Embodiment 3

[0044] Example 3 Under acidic pH value and continuous flow operation mode, a new method for the production of fatty acids by indirect fermentation of biomass using mixed flora in hollow fiber membrane reactors.

[0045] The device used adopts the device in embodiment 1, such as figure 1 shown. In this embodiment, the hollow fiber membrane reactor 1 is made of organic glass. The shell has an inner diameter of 3.5cm and a height of 30cm. 1cm, 2cm, 14cm, 20cm, and 25cm from the lower end are respectively provided with 3 connection ports of the medium supply device, 6 water inlets of the reaction system circulation system, 13 sampling ports, 6 circulation ports of the reaction system circulation system and 4 connections of the reactant recovery device mouth. The hollow fiber membrane bundle 10 is made up of 30 polyethylene hollow fiber membranes. The effective length of the membranes is 22cm, the inner diameter is 1mm, and the outer diameter is 1.1mm. The air port 11 runs thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Effective length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com