Method for preparing caproic acid through two-phase process anaerobic fermentation

A technology of anaerobic fermentation and caproic acid, applied in fermentation and other directions, can solve problems such as inhibition of carbon chain extension process, and achieve the effect of promoting production, efficient coupling, and good research and application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

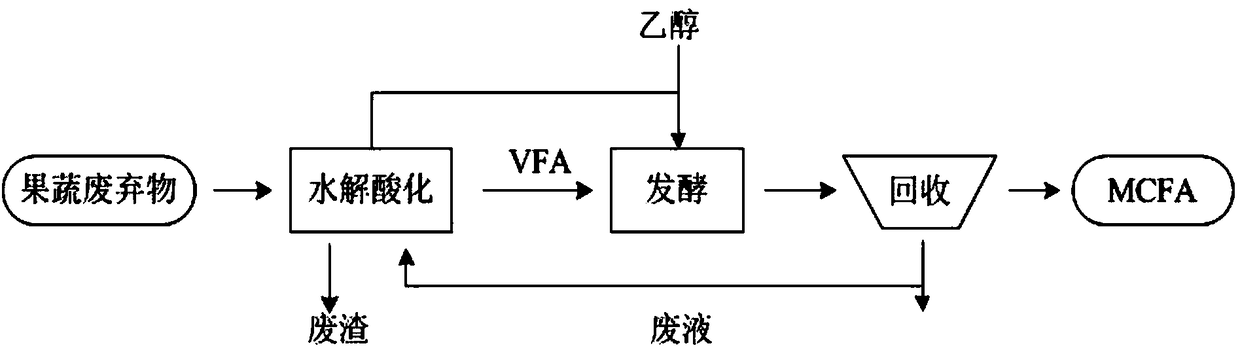

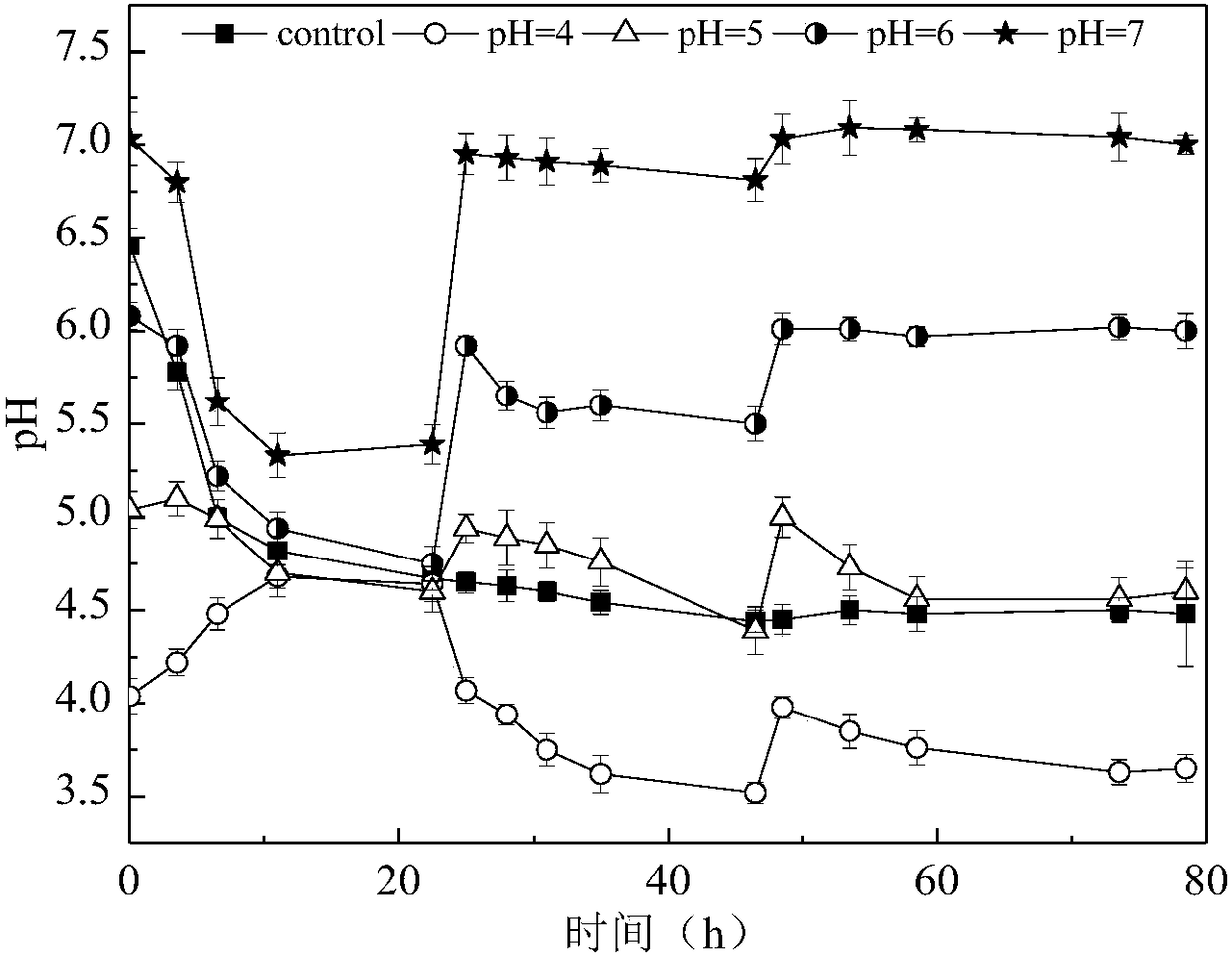

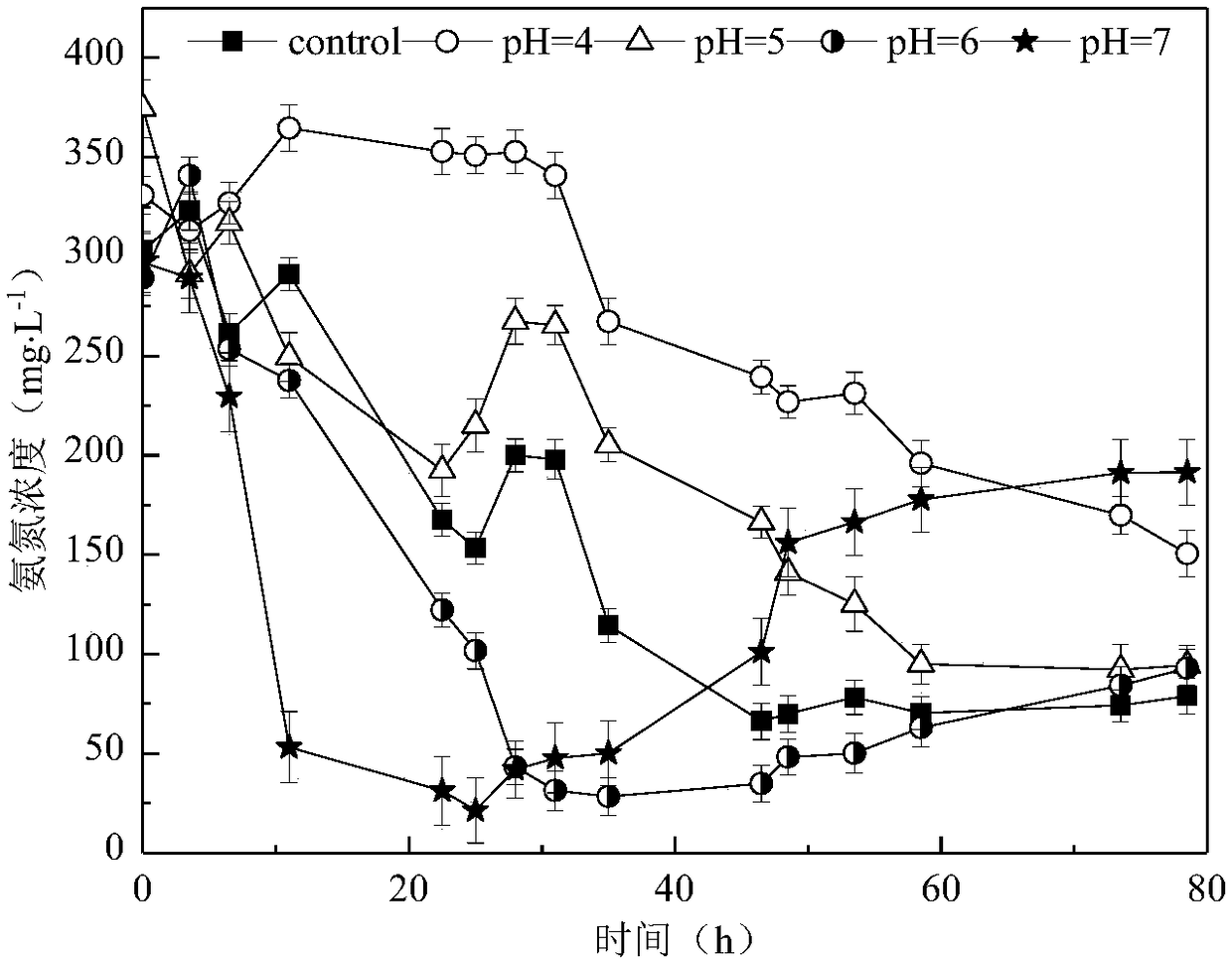

[0027] Anaerobic acid production process such as figure 1 shown. Five groups were set up for the acid production phase. The substrate was fruit and vegetable residues. The inoculum sludge was taken from a sewage anaerobic digestion tank of a food processing factory in Wuxi. The inoculation ratio was 2:1 and the total TS was 5%. The initial pH was adjusted to 4, 5, 6, and 7 respectively, and the unadjusted pH system was used as a control experiment. In order to maintain the pH stability, 3 mol·L -1 NaOH solution adjusts the pH. The reaction device is an anaerobic bottle plus a gas bag, with an effective volume of 1L, placed in a 35°C constant temperature water bath.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com