Wine making multi-bacteria functional bacterial liquid, and production method and application thereof

A production method and technology of functional bacteria, applied in the field of multi-microfunctional bacterial liquid for brewing, can solve the problems of poor wine quality, small variety and quantity, etc., and achieve the effect of good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

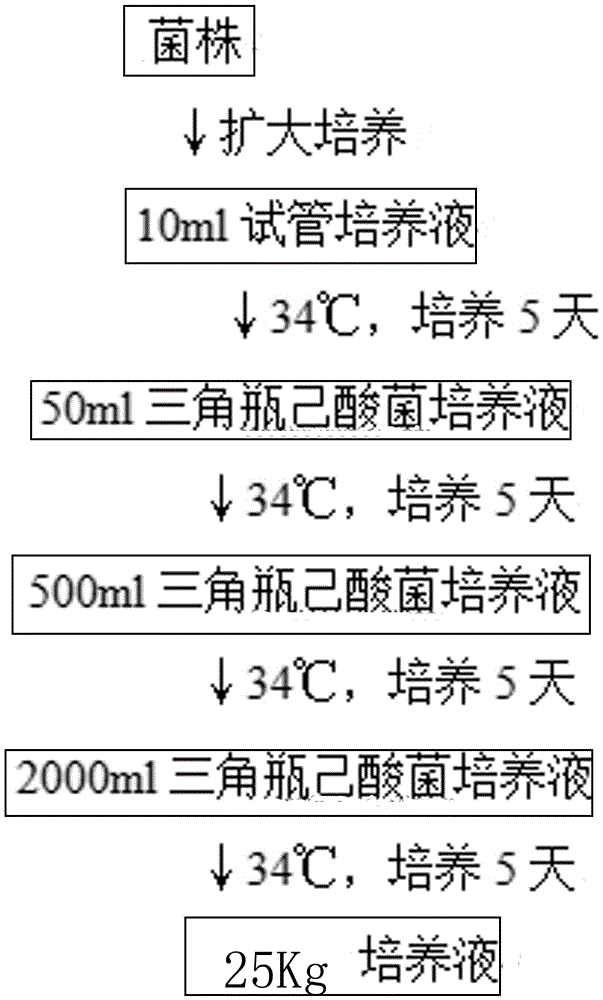

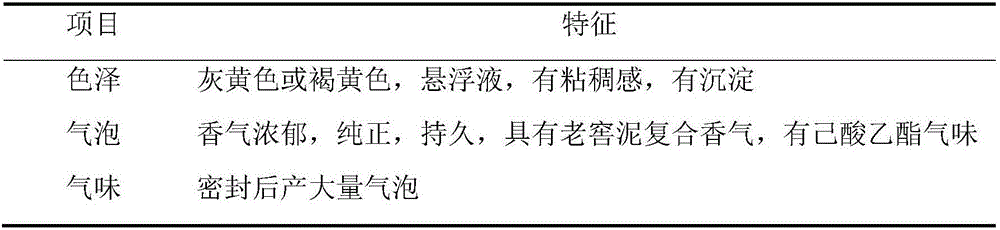

Method used

Image

Examples

Embodiment 1

[0045] (1) Isolation and purification of caproic acid bacteria

[0046] Weigh the selected high-quality old pit mud, use aseptic operation, add it to the liquid culture medium (Pasteur culture medium without agar), cultivate it under vacuum conditions for 7 days, select the test tubes that produce gas early and produce more gas, and use 15 % of the inoculum was re-enriched and cultured in the same way.

[0047] Heat-treat the selected test tube in a 90°C water bath for 12 minutes, absorb 1 mL of caproic acid bacteria solution, and dilute to 10 by 10-fold dilution method. -6 , take the last three dilutions, use the plate separation method, separate several times under aseptic conditions in Pasteur medium (plus agar), until the colony shape is consistent, check the strains with robust cell shape under the microscope, and select the strains with high hexanoic acid production strain.

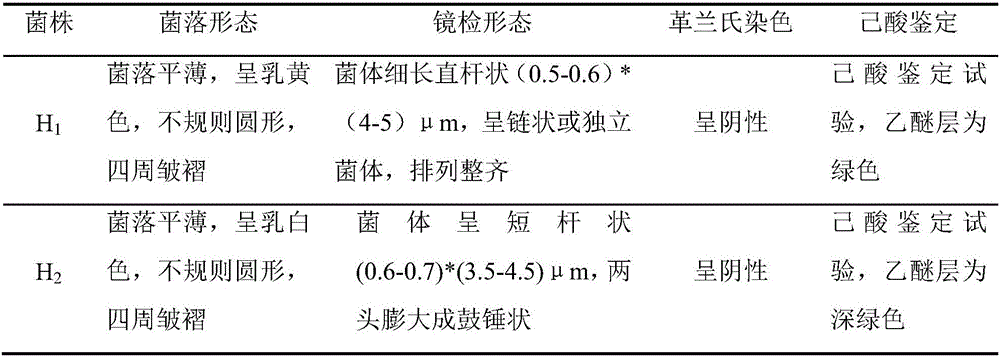

[0048] A total of 2 strains were isolated from Zhijiang Laojiao Mud. The morphological charact...

Embodiment 2

[0080] Analyze the influence of the components of the brewing multi-microfunctional bacterial liquid of the present invention on the flavor substances of the brewed liquor. The comparison schemes of different multi-microfunctional bacterial liquid components are shown in Table 6. Components 1-5 are used for fermentation respectively, and the liquor base wine obtained is trace The composition analysis is shown in Table 7.

[0081] Table 6 Comparison scheme of components of brewing multi-microfunctional bacterial liquid of the present invention (ratio by weight and number)

[0082]

[0083]

[0084] Note: The concentration of caproic acid bacteria in the caproic acid bacteria culture solution is 2.0*107-3.5*10 7 individual / mL.

[0085] Table 7 Analysis data of wine sample under the comparison of multi-microfunctional bacterial liquid components (mg / 100mL)

[0086]

[0087] As can be seen from Table 7, using the component 2 in Table 6, the multi-microfunctional bacteri...

Embodiment 3

[0089] The present invention adopts the method of series steaming to enhance aroma, and analyzes the influence factors of winemaking natural by-product components on the production of liquor flavor substances in the wine-making multi-microfunctional bacterial liquid. The comparison schemes of different multi-microfunctional bacterial liquid components are shown in Table 8. Components 6-12 were fermented, and the analysis of the trace components of the liquor base liquor obtained is shown in Table 9.

[0090] Table 8 Analysis table of influencing factors of multi-microfunctional bacterial liquid components on string steaming and aromatherapy

[0091]

[0092] Table 9 Analysis data of multi-microfunctional bacterial liquid components on the influence factors of string steaming and aroma extraction process (mg / 100mL)

[0093]

[0094]

[0095] As can be seen from Table 9, when component 8 lacks caproic acid bacteria functional bacteria, the content of ethyl caproate, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com