Mixed culture bacterial solution for quickly aging new pit of strong aromatic Chinese spirits and maintenance method

A technology of mixed cultivation of Luzhou-flavor liquor, applied in the field of microorganisms, to achieve the effects of fast aging of pit mud, improvement of bacterial group structure, and optimization of bacterial group structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

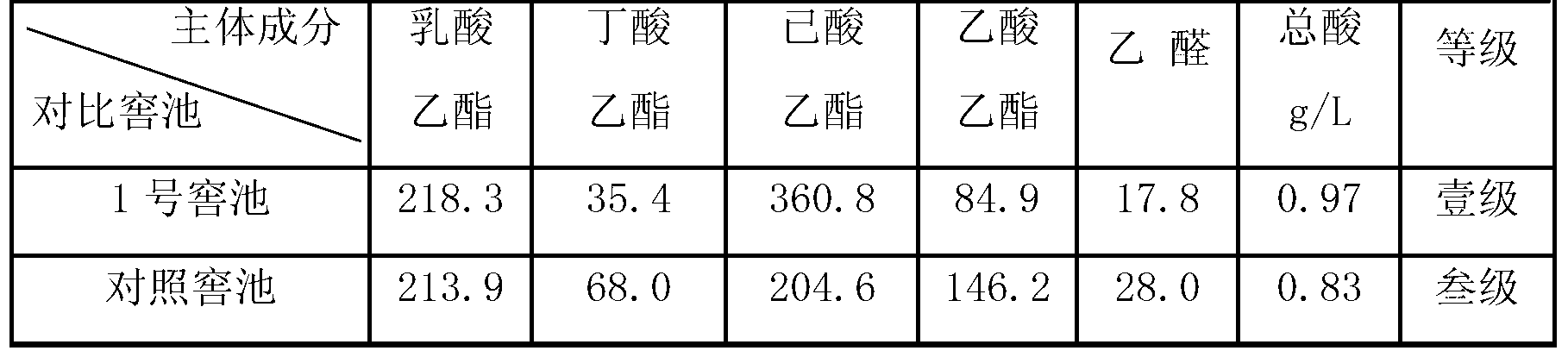

[0035] Two new cellars with the same wine production quality and built in the same batch were selected for comparative experiments, and the No. 1 cellar was processed according to the following steps:

[0036] 1. The preparation and processing method of multi-component culture cellar liquid:

[0037] (1) The mixed liquid of Methanobacteria selected from artificial liquid culture, added with 1‰ of yeast extract and cultured at 35°C for 30 days is the Methanobacteria culture medium.

[0038](2) Artificial liquid culture screened caproic acid strains with good performance in caproic acid production, added yeast extract 1‰, sodium acetate 5‰, 95Vol% alcohol 2%, dipotassium hydrogen phosphate 0.25‰, pH adjusted to 6.8, at 35°C Under constant temperature conditions, the liquid anaerobic culture culture liquid for 7 days is the caproic acid bacteria culture liquid.

[0039] (3) Select mature high-quality old pit mud and cold boiled water at 40°C, and add yeast extract 1‰, sodium ace...

Embodiment 2

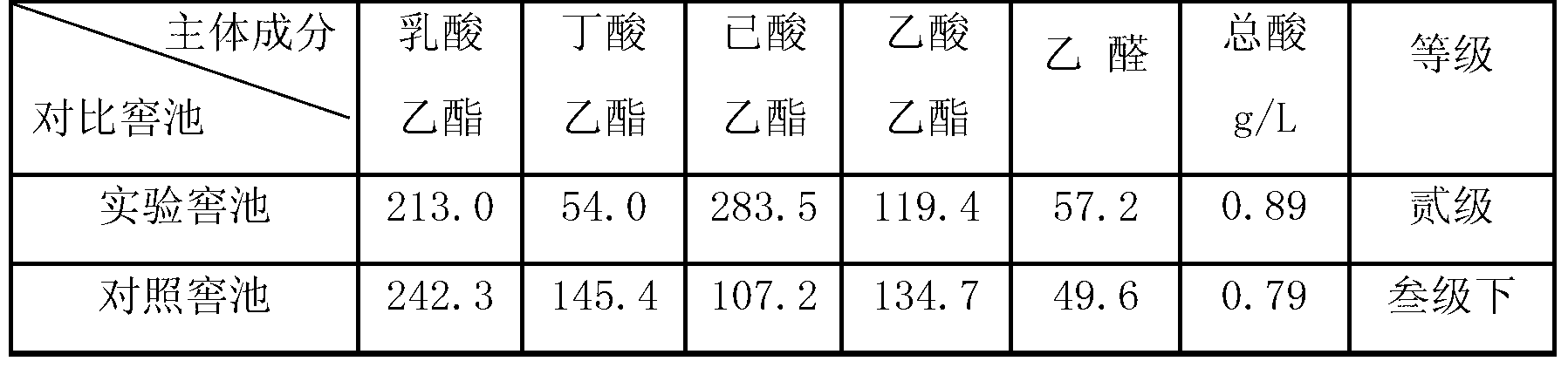

[0048] Two cellars with similar wine production quality and degradation degree were selected for comparative experiments.

[0049] 1. The preparation and processing method of multi-component culture cellar liquid:

[0050] (1) The mixed liquid of Methanobacteria selected from artificial liquid culture, added with 1‰ of yeast extract and cultured at 35°C for 30 days, namely the Methanobacterium culture liquid.

[0051] (2) Artificial liquid culture screened caproic acid strains with good performance in caproic acid production, added yeast extract 1‰, sodium acetate 5‰, 95Vol% alcohol 2%, dipotassium hydrogen phosphate 0.25‰, pH adjusted to 6.8, at 35°C Under constant temperature conditions, the liquid anaerobic culture for 10 days is the culture liquid of caproic acid bacteria.

[0052] (3) Select mature high-quality old pit mud and cold boiled water at 40°C, add yeast extract 1‰, sodium acetate 5‰, and dipotassium hydrogen phosphate 0.25‰ according to the ratio of 1:0.8, mix ...

Embodiment 3

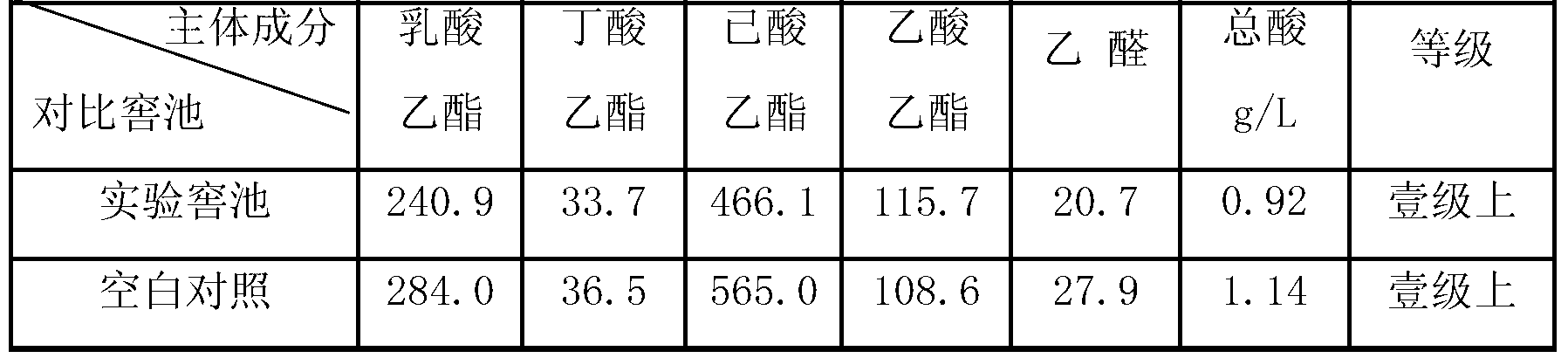

[0061] A new cellar and a mature old cellar were selected to carry out comparative experiments, and the new cellars were processed by the method of the present invention.

[0062] 1. The preparation and processing method of multi-component culture cellar liquid:

[0063] (1) The mixed liquid of Methanobacteria selected from artificial liquid culture, added with 1‰ of yeast extract and cultured at 35°C for 30 days, namely the Methanobacterium culture liquid.

[0064] (2) Artificial liquid culture screened caproic acid strains with good performance in caproic acid production, added yeast extract 1‰, sodium acetate 5‰, 95Vol% alcohol 2%, dipotassium hydrogen phosphate 0.25‰, pH adjusted to 6.8, at 35°C Under constant temperature conditions, the liquid anaerobic culture for 10 days is the culture liquid of caproic acid bacteria.

[0065] (3) Select mature high-quality old pit mud and cold boiled water at 40°C, add yeast extract 1‰, sodium acetate 5‰, and dipotassium hydrogen phos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com