Cementing sliding sleeve

A sliding sleeve and well cementing technology, which is applied in the direction of wellbore/well components, wellbore/well valve devices, production fluids, etc., can solve the problem of unconventional oil and gas reservoirs such as shale gas with high-efficiency development and intelligent sliding sleeve operation complex problems, to achieve the effects of simplified fracturing operations, fast timeliness, and efficient development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

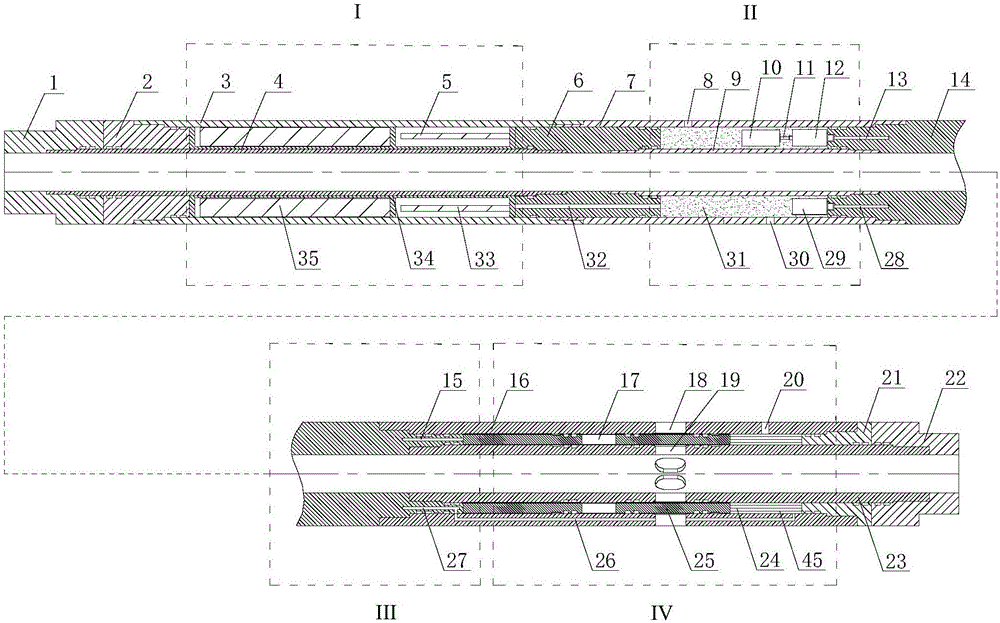

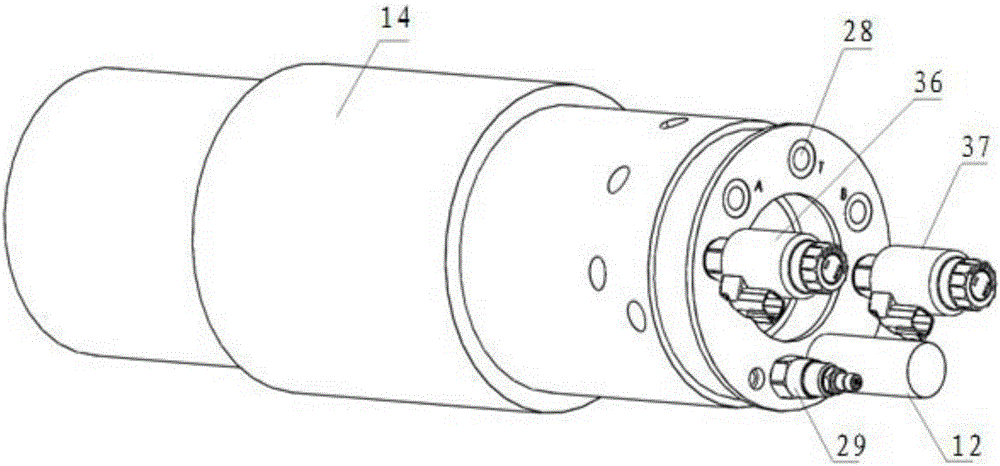

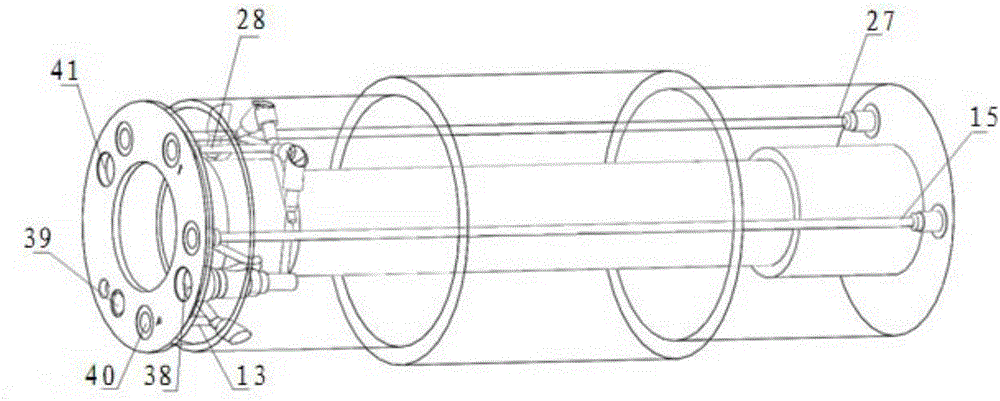

[0030] see figure 1 , the embodiment of the present invention provides a cementing sliding sleeve, the cementing sliding sleeve is a hollow tubular structure, including an upper joint 1, an electrical sub-section I, a hydraulic control sub-section II, and a reversing sub-section III, which are sequentially connected in the axial direction , Sliding sleeve pup joint IV and lower joint 22.

[0031] Among them, the sliding sleeve nipple IV includes: sliding sleeve outer cylinder 16, sliding sleeve inner cylinder 23, and an annular sliding sleeve cavity 45 is formed between the sliding sleeve outer cylinder 16 and the sliding sleeve inner cylinder 23;

[0032] The sliding sleeve cavity 45 is provided with a sliding sleeve 25; the side wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com