Cathode plate for lithium-ion capacitor and production method of cathode plate

A technology for negative electrode sheets and capacitors, which is applied in the field of preparation of negative electrode sheets for lithium ion capacitors, can solve the problems of complex process, long process time, uneven lithium intercalation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

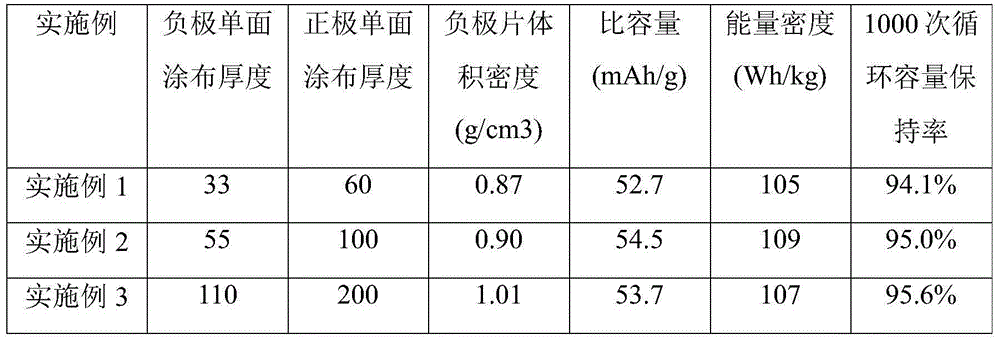

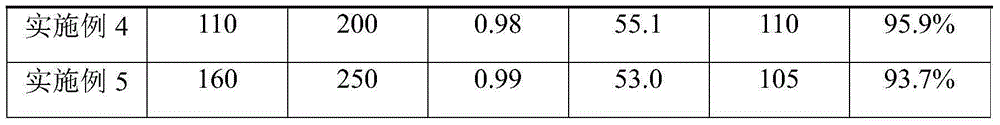

Examples

Embodiment 1

[0058] Coating for the first time: (1) first inject 150wt% deionized water into the stirring disperser, then add 2wt% sodium carboxymethylcellulose in the mixing tank, and stir for 360min at a speed of 20r / min; (2 ) Add 4wt% Super-P Li to the stirring tank, stir for 60min at a speed of 20r / min; (3) add 90wt% artificial graphite to the stirring tank, stir at a low speed of 20r / min for 10min, and wait until fully wetted , evacuate to -0.098Mpa, stir in vacuum at a speed of 20r / min, open the high-speed dispersing shaft at the same time, disperse with a speed of 4000r / min, and the time of vacuum stirring and dispersing is 240min; (4) Add 4wt% of Styrene-butadiene rubber (bonding agent I), vacuumize to -0.098Mpa, and stir in vacuum at a speed of 20r / min for 60min; (5) pass the above-mentioned slurry through a 150-mesh sieve; (6) utilize a transfer coater to coat On the front and back sides of 9μm thick copper foil, the thickness of one side coating is 30μm (after drying), the coati...

Embodiment 2

[0066] Coating for the first time: (1) first add the artificial graphite of 93wt% and the graphene of 2wt% in stirring disperser, stir at low speed 60min with the rotating speed of 20r / min; (2) add 75wt% in advance The prepared sodium carboxymethyl cellulose solution with a concentration of 2wt% ensures that the quality of the added sodium carboxymethyl cellulose is 1.5wt%. At the same time, turn on the high-speed dispersing shaft to disperse at a speed of 4000r / min, and the vacuum stirring and dispersing time is 240min; (3) Add 2.5wt% styrene-butadiene rubber to the mixing tank, and at the same time add 126.wt5% deionized water, vacuumed to -0.098Mpa, and vacuum stirred at a speed of 20r / min for 60min; (4) passing the above slurry through a 150-mesh sieve; (5) using a transfer coater to coat 9μm thick copper On the front and back sides of the foil, the coating thickness on one side is 50 μm (after drying), the coating speed is 3 m / min, and it is dried in a blast drying oven a...

Embodiment 3

[0070]Coating for the first time: (1) inject 146wt% deionized water into the stirring disperser at first, then add the polyacrylic acid-2 ethylhexyl aqueous binding agent of 5wt% in the mixing tank (the mass fraction of this emulsion 15wt%), stirred at a speed of 30r / min for 240min; (2) added 4wt% Super-P Li to the stirring tank, and stirred at a speed of 30r / min for 60min; (3) added 91wt% of Super-P Li to the stirring tank Artificial graphite, stirred at a low speed of 20r / min for 10min, after being fully wetted, vacuumed to -0.098Mpa, stirred in vacuum at a speed of 40r / min, at the same time turned on the high-speed dispersion shaft, dispersed at a speed of 4000r / min, vacuum stirred and The dispersion time is 120min; (4) pass the above slurry through a 200-mesh sieve; (5) use a transfer coating machine to coat the front and back sides of a 9 μm thick copper foil, and the coating thickness on one side is 100 μm (drying After), the coating speed is 2m / min, and it is dried at 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com