In-situ testing method for deep underground engineering during rockburst preparation and evolution process

A technology of evolution process and in-situ testing, applied in basic structure engineering, on-site foundation soil survey, earthwork drilling and mining, etc., can solve problems that have not been reported in the literature, and achieve the goal of improving reliability, facilitating mutual verification and comparative analysis Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

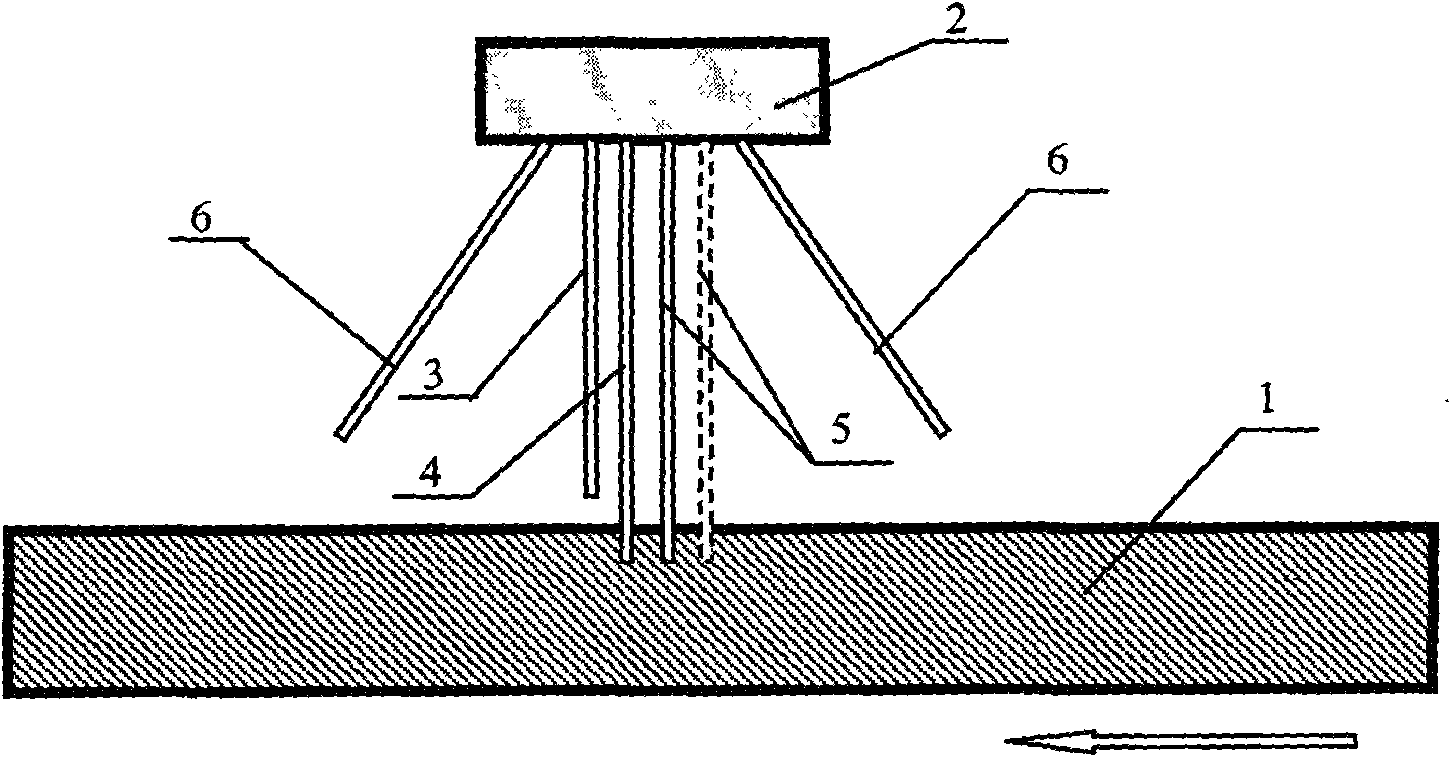

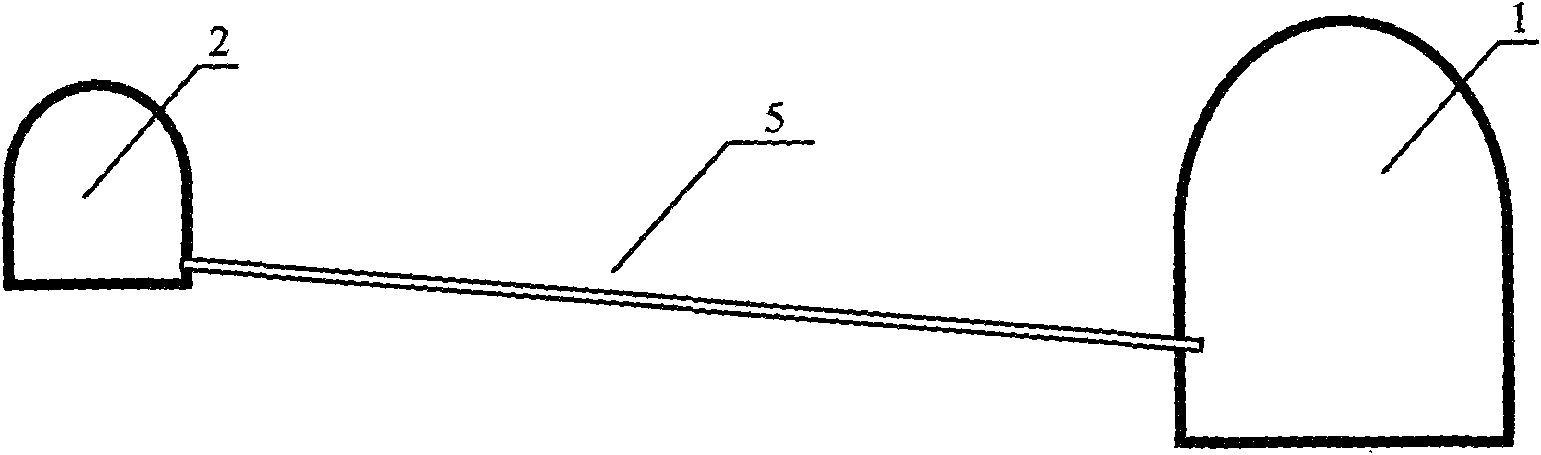

[0030] In this example, a rockburst in-situ test was carried out on the excavation process of a tunnel with a depth of 2370m. The layout of the tunnel and monitoring boreholes is as follows: Figure 4 As shown, the diameter of test tunnel 1 is 7.5×8.0m, and the specific steps and methods are as follows:

[0031] (1) A test branch tunnel 2 parallel to the test tunnel 1 was excavated at a distance of 25m from the side of the test tunnel 1, and the floor of the test branch tunnel 2 was 1.5m higher than the floor of the test tunnel 1;

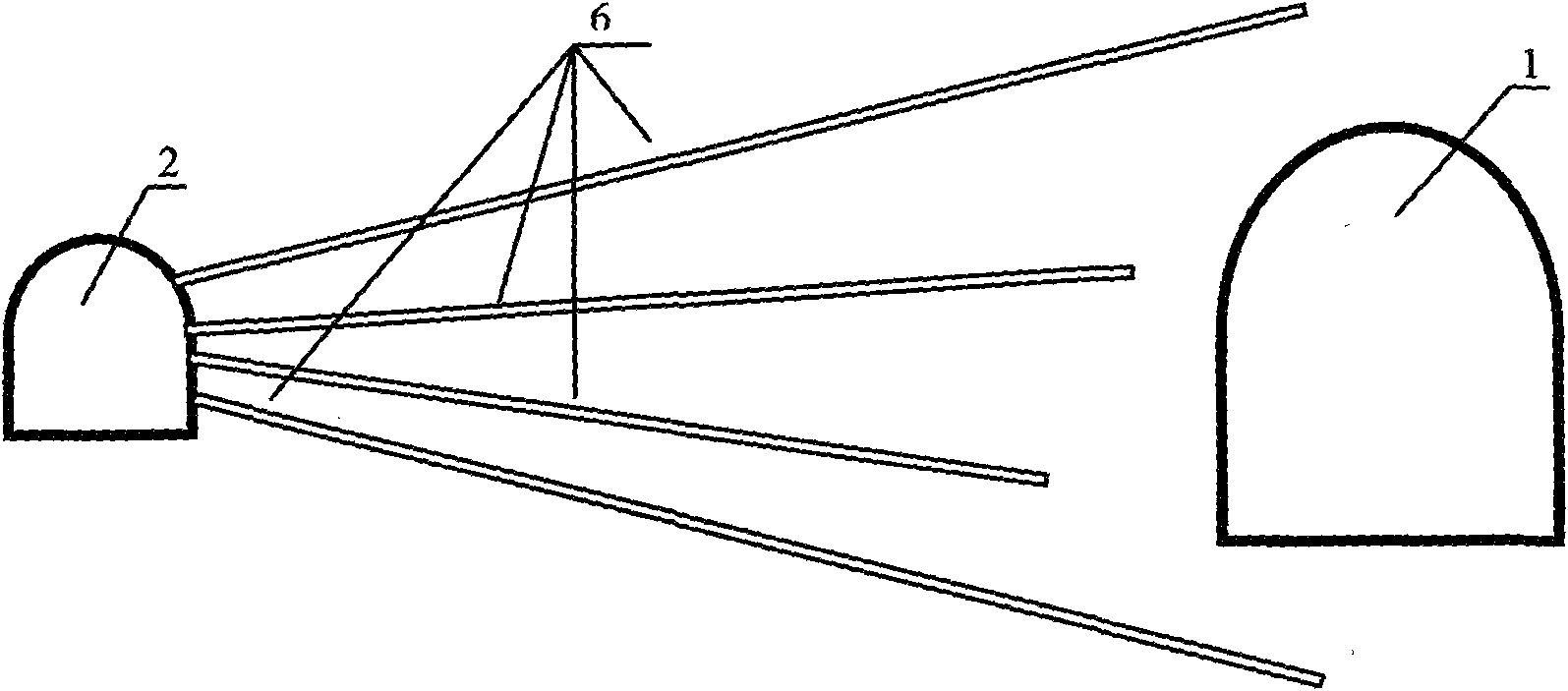

[0032] (2) Select Figure 4 The monitoring section is arranged in the area of 4.0m in the excavation direction of the test tunnel 1 shown, and the test branch hole 2 is drilled in the direction of the test tunnel 1, and a series of test holes with a downward slope of 2° are arranged, that is, the sliding micrometer hole 3 and the digital camera hole 4 and acoustic wave holes 5, and radially distributed microseismic test holes 6. The bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com