Precast beam and column connecting device and manufacturing method thereof

A beam-column connection and connector technology, which is applied in construction, building structure and other directions, can solve the problems of lack of safe and reliable precast concrete components on-site connection method, long maintenance time, shortening the construction time of the main project, etc., and is conducive to noise control. , Shorten the construction period, and is conducive to the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

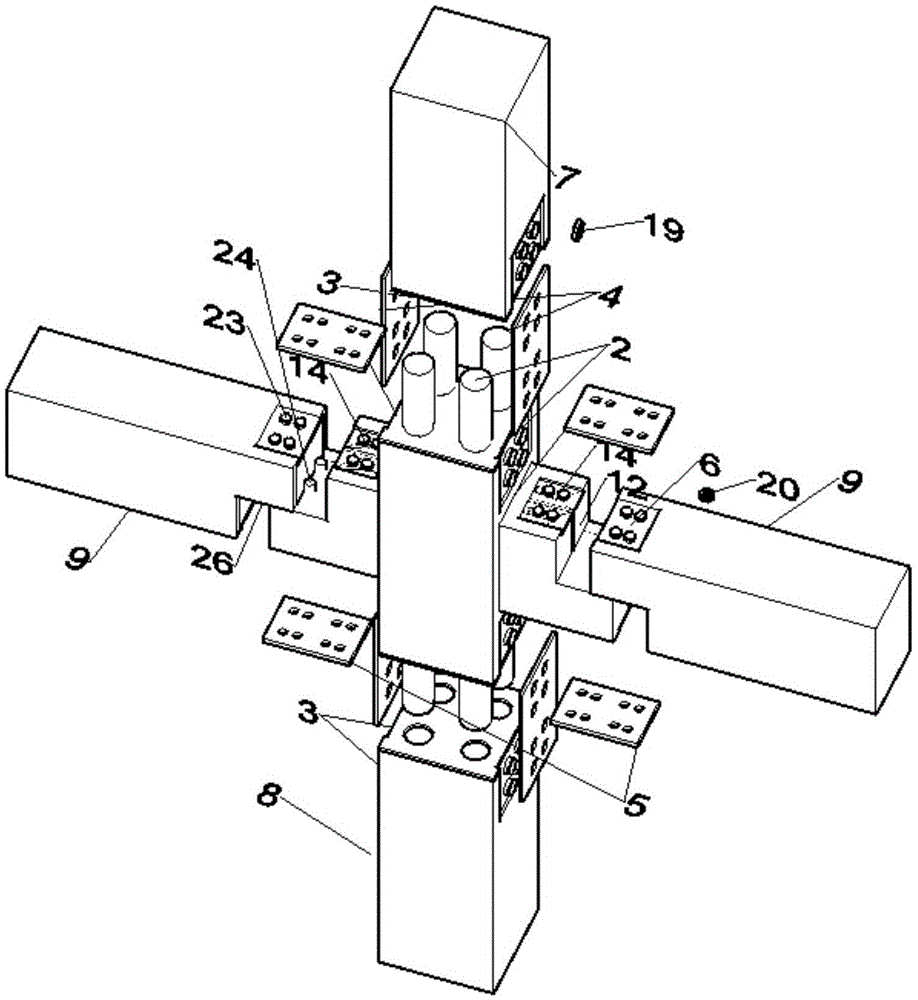

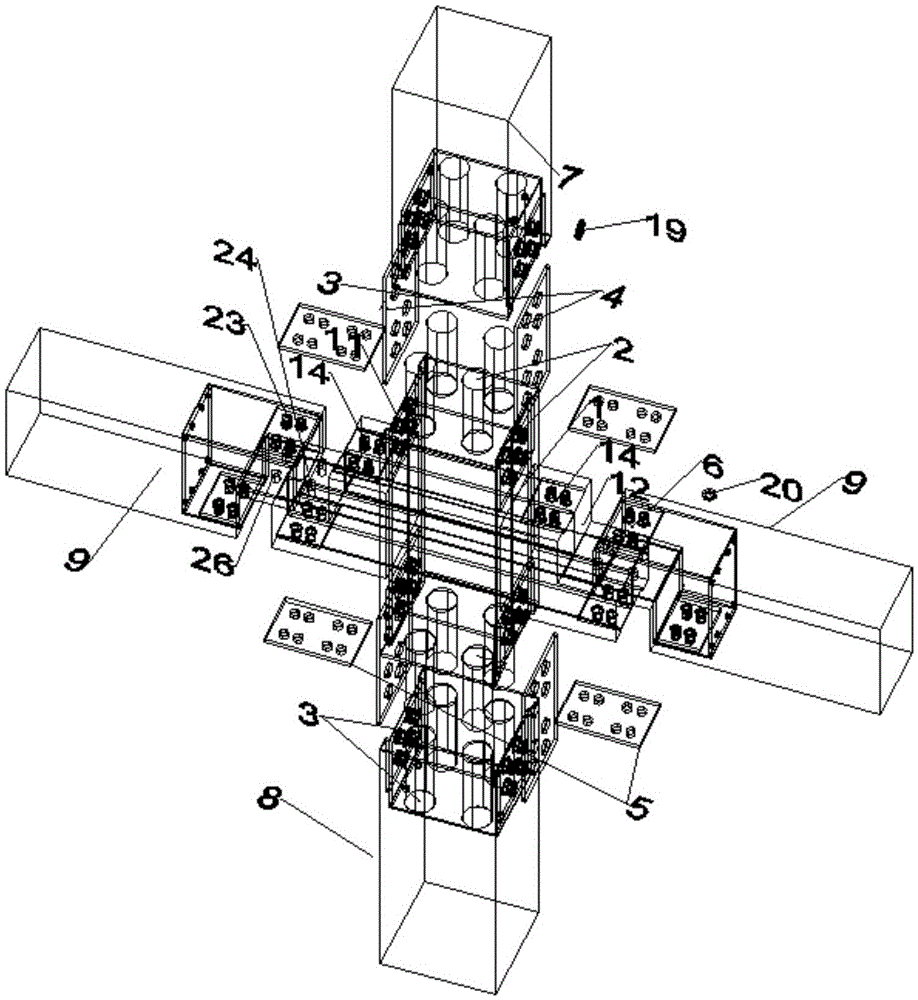

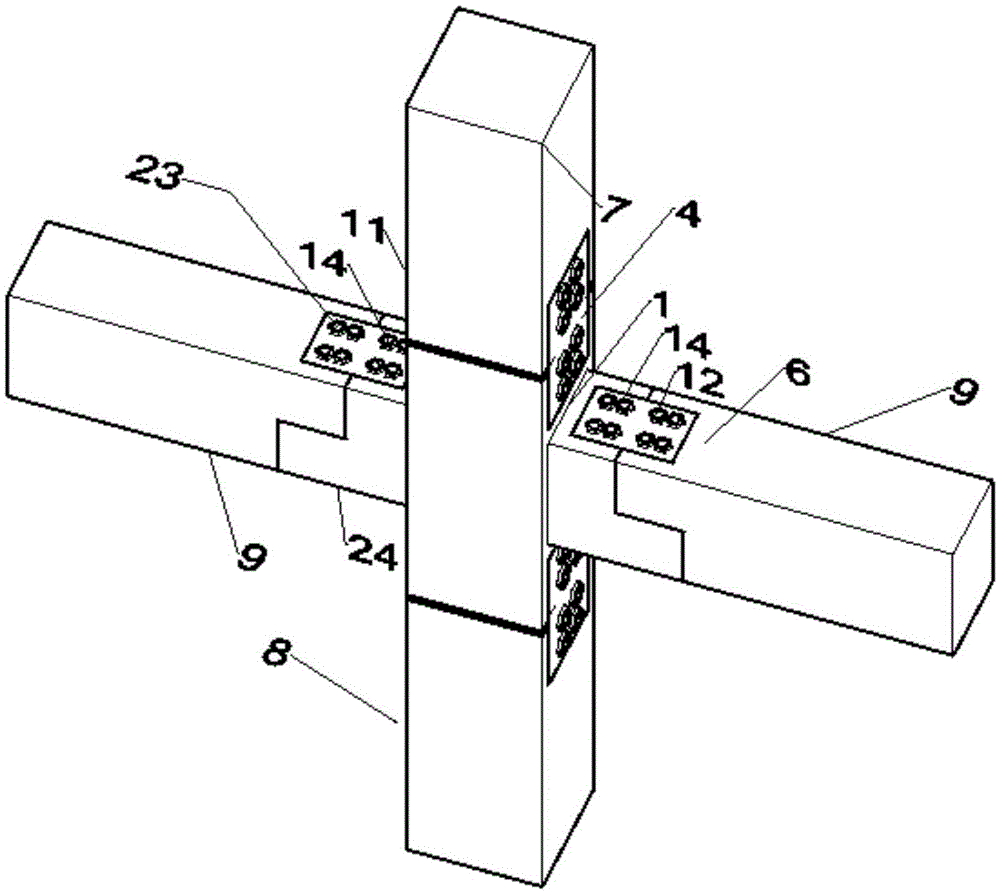

[0034] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0035] In the existing technology, most of the concrete frame connection nodes are cast-in-situ or prefabricated wet connections. The cumbersome binding of steel bars affects the construction progress, the quality of on-site construction cannot be guaranteed, and the wet construction will have negative impacts on the surrounding environment and residents. The invention provides a prefabricated beam-column connection device, which is a new type of prefabricated frame dry connection node, without the need for concrete pouring and steel bar binding at the construction site, which is convenient for construction, quick in operation, shortens the construction period, and is benef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com