Triaxial mechanical test device and method capable of simulating formation condition of deep-buried artificial frozen soil

A technology of triaxial mechanics and artificial frozen soil, which is applied in the direction of applying stable tension/pressure to test material strength, measuring devices, earth cube drilling and mining, etc., which can solve the problem of long test time, expensive test machine time, and inability to carry out efficiently Problems such as mechanical tests of deep-buried artificial frozen soil samples, to improve test accuracy and prevent freezing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

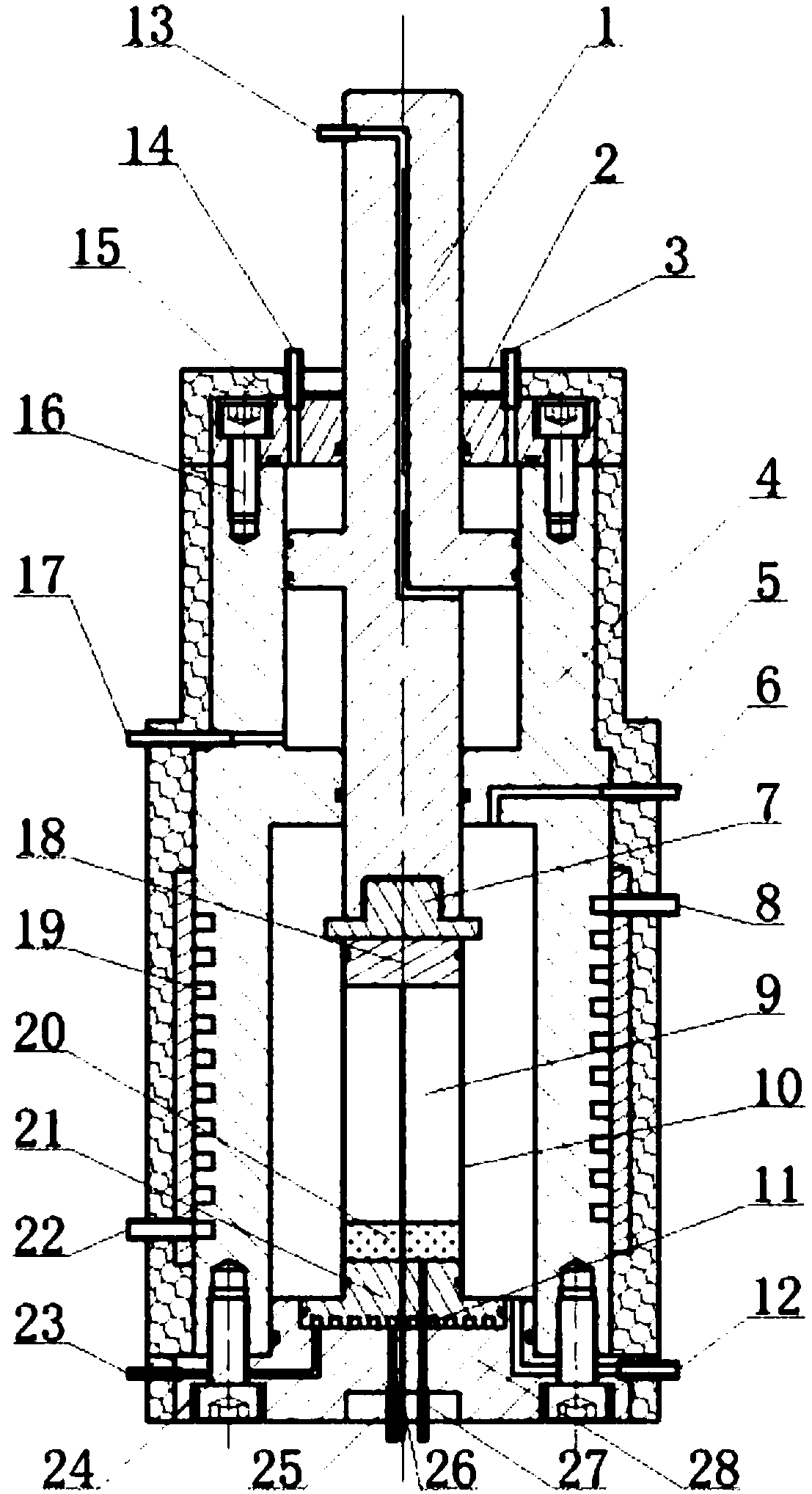

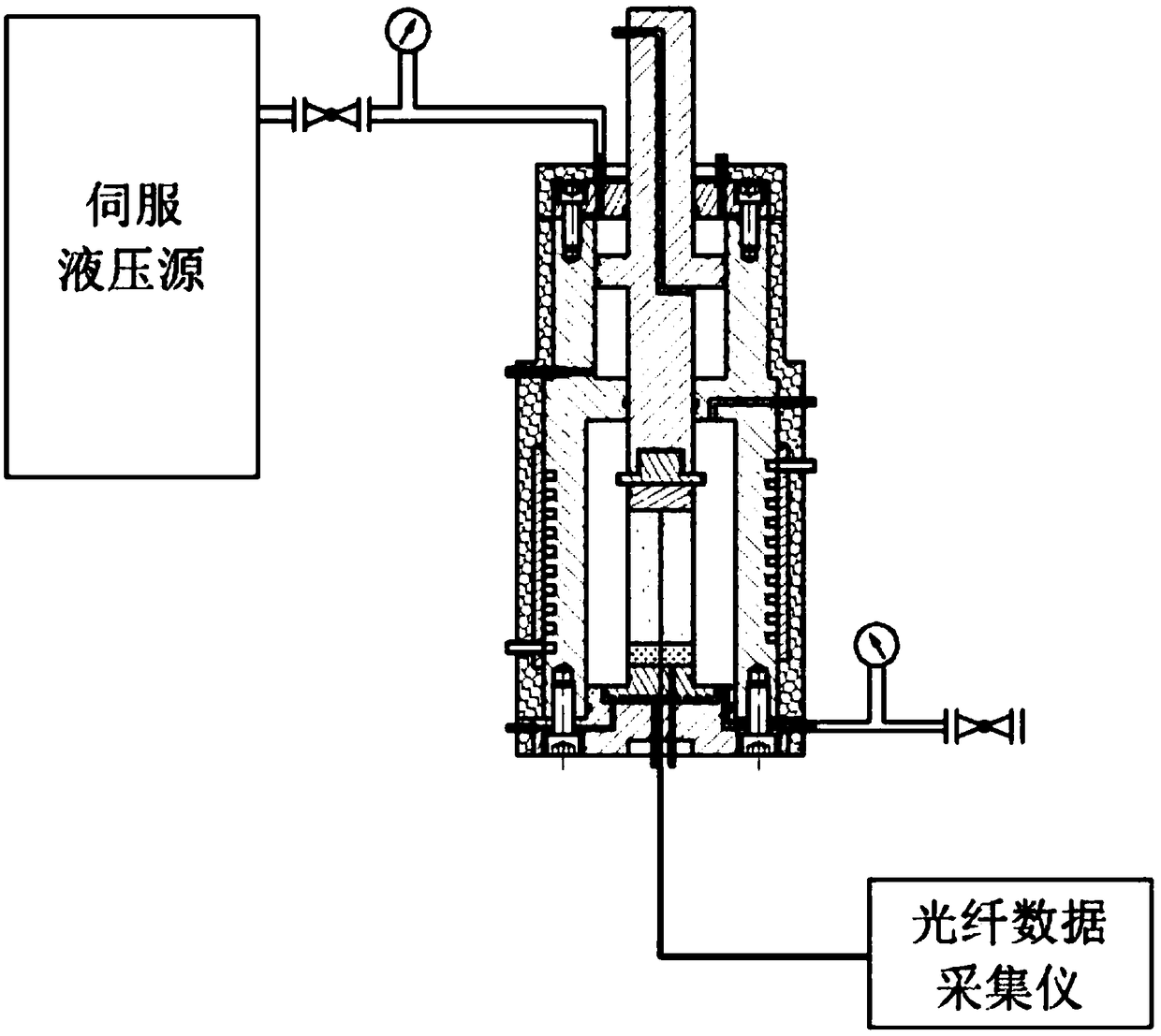

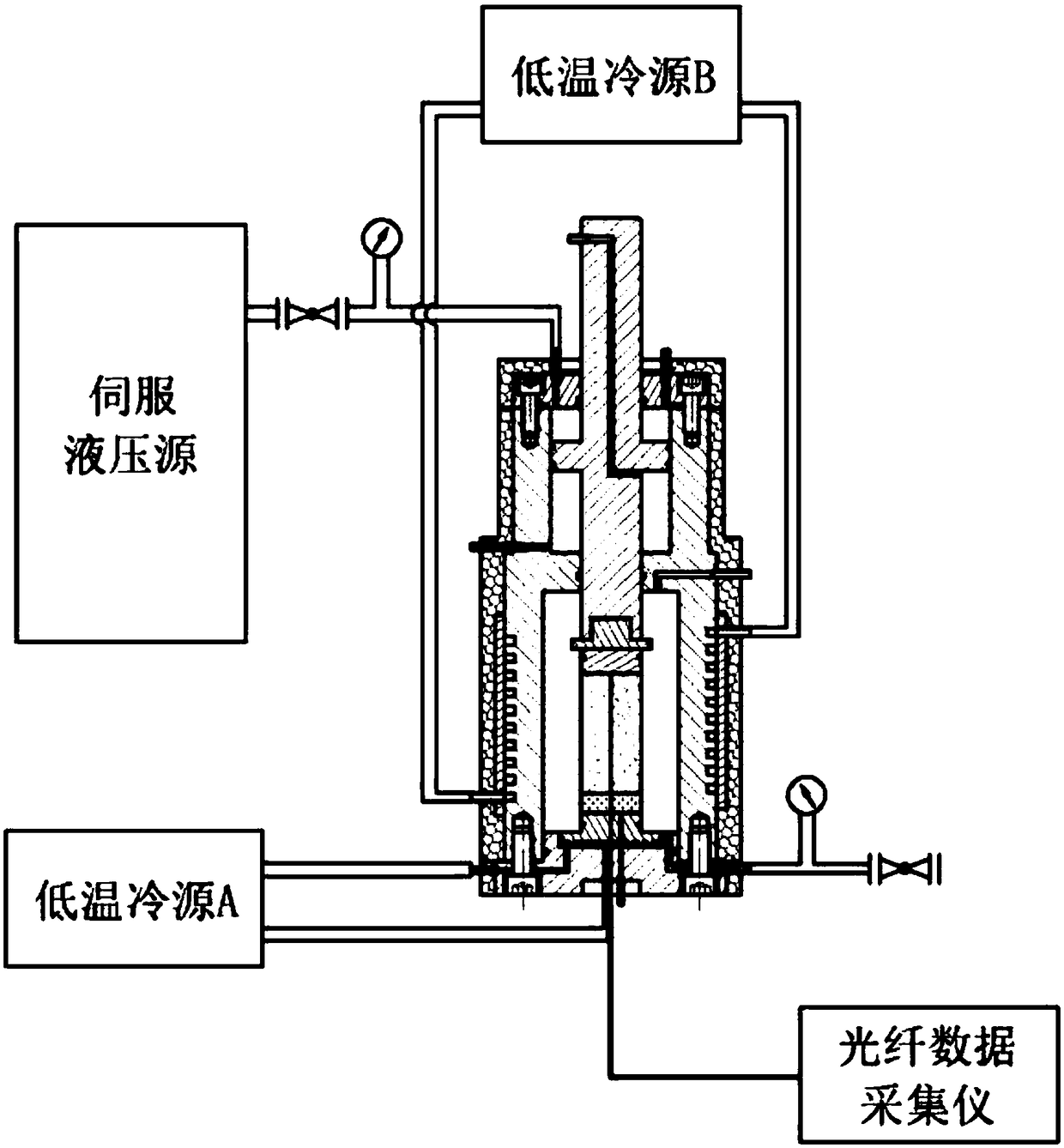

[0038] Such as figure 1 As shown, the triaxial mechanical test device capable of simulating the formation conditions of deep-buried artificial frozen soil of the present invention is mainly composed of a main body loading system, a freezing system and a sample testing system;

[0039] The main body loading system includes a chassis 28, a pressure bearing cylinder 4, a flange 15, a sample base 21, an axial pressure piston rod 1, a piston end 7, an axial pressure loading chamber inlet pipe 14, and an axial pressure loading chamber exhaust Pipe 3, the inlet pipe 17 of the axial pressure balance chamber, the exhaust pipe 13 of the axial pressure balance chamber, the liquid inlet pipe 12 of the confining pressure chamber, the exhaust pipe 6 of the confining pressure chamber and the external existing servo control hydraulic source; the flange plate 15, The pressure-bearing cylinder 4 and the chassis 28 constitute a pressure-bearing shell; the pressure-bearing shell is covered with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com