Reinforced concrete foundation for mounting assembled tower crane

A reinforced concrete and prefabricated technology, applied in the direction of infrastructure engineering, construction, etc., can solve problems such as costly manual smashing or blasting, affecting engineering construction, and difficult to deal with, so as to ensure safety and physical and mental health, keep clean and hygienic, The effect of high reuse rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

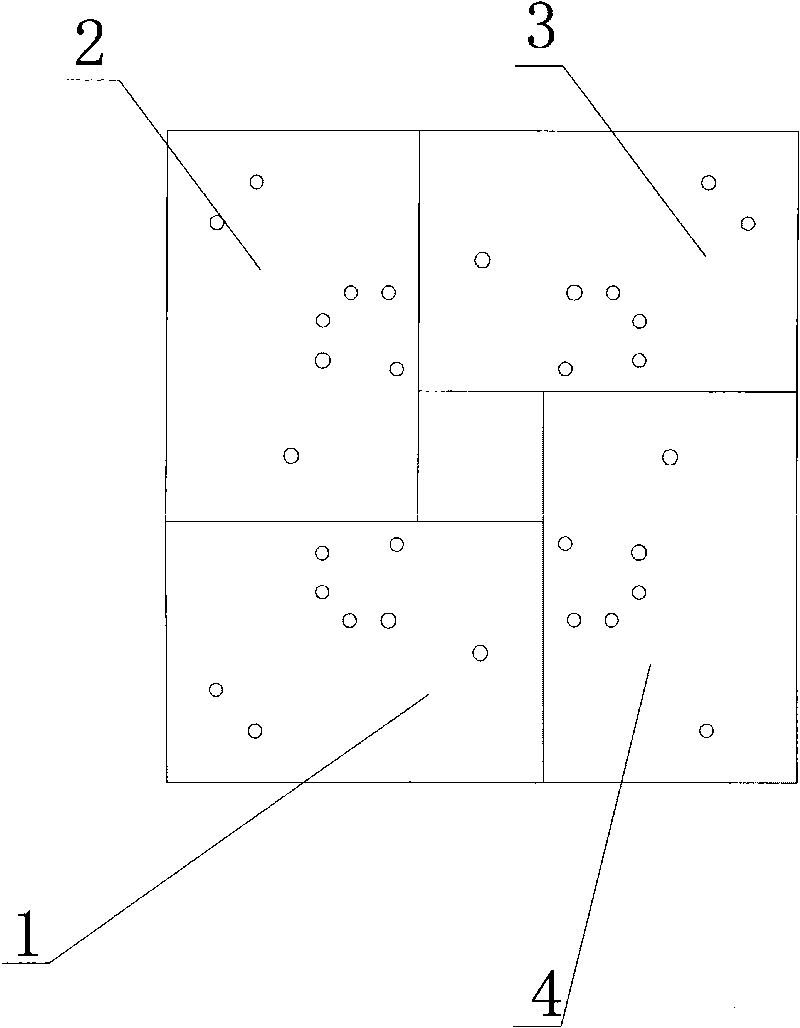

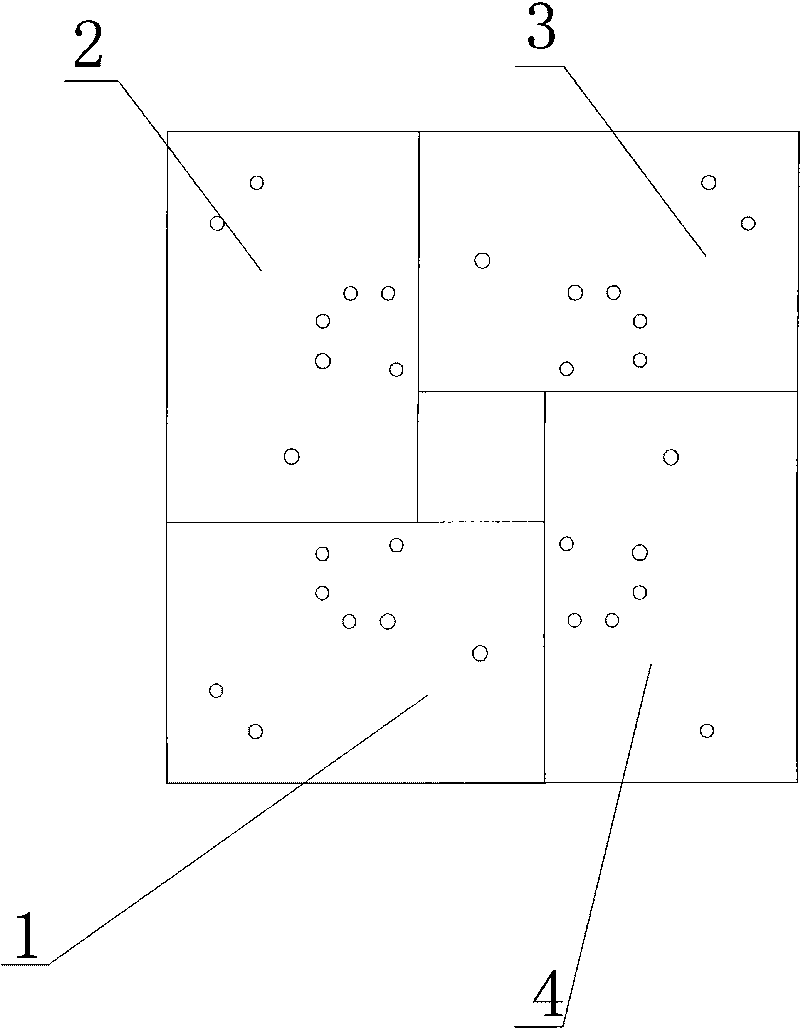

[0022] figure 1 Provided is a schematic plan view of the lower structure of a prefabricated tower crane installed with a reinforced concrete foundation of the present invention, 8 rectangular reinforced concrete blocks with the same shape and size, wherein rectangular reinforced concrete block 1, rectangular reinforced concrete block 2, and rectangular reinforced concrete blocks The concrete block 3 and the rectangular parallelepiped reinforced concrete block 4 form a "back" shape on the same plane.

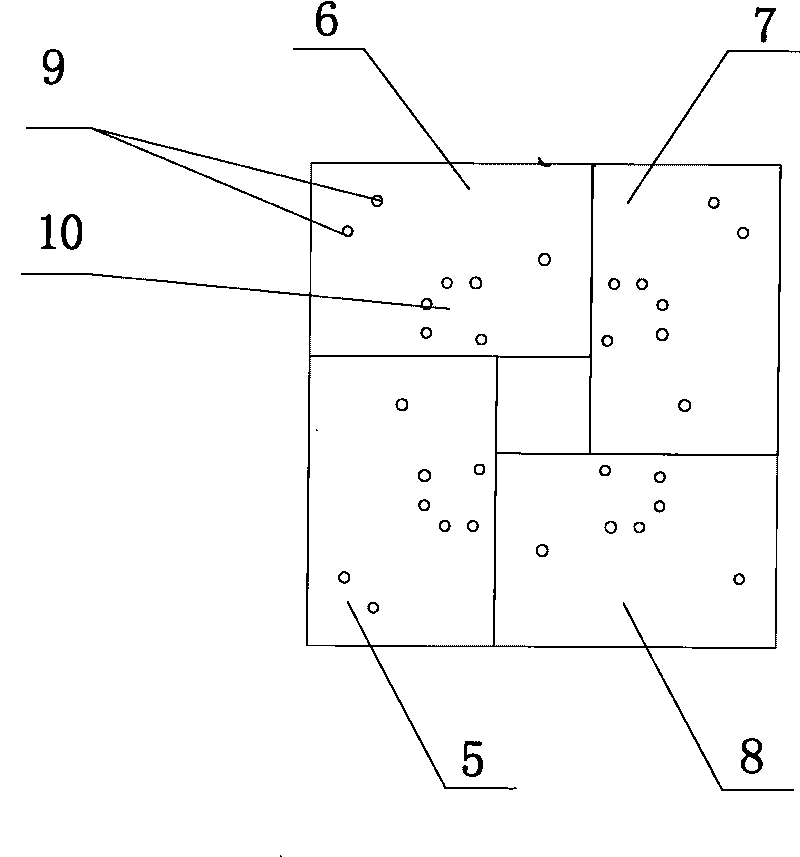

[0023] figure 2 Provided is a schematic plan view of the superstructure of a prefabricated tower crane installed with reinforced concrete foundations of the present invention, cuboid reinforced concrete block 5, cuboid reinforced concrete block 6, cuboid reinforced concrete block 7, and cuboid reinforced concrete block 8 are also surrounded on the same plane. Into the shape of "back". Two "back" shapes are stacked up and down together, wherein, the upper rectangular reinforced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com